Iron phosphate comprehensive wastewater resourceful treatment device and method

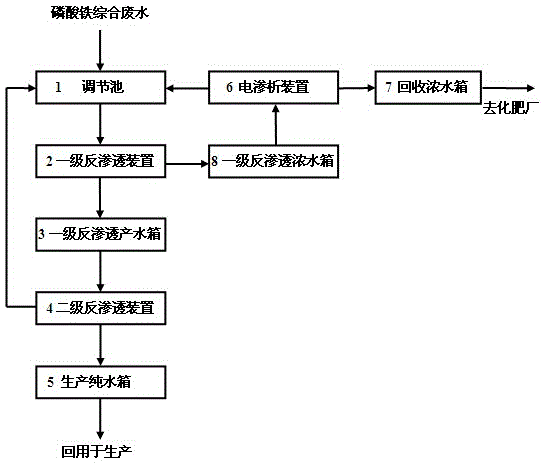

A technology that integrates wastewater and treatment methods, and is applied in the fields of natural water treatment, chemical instruments and methods, and multi-stage water/sewage treatment to achieve high-efficiency recovery, simple process flow, and good social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

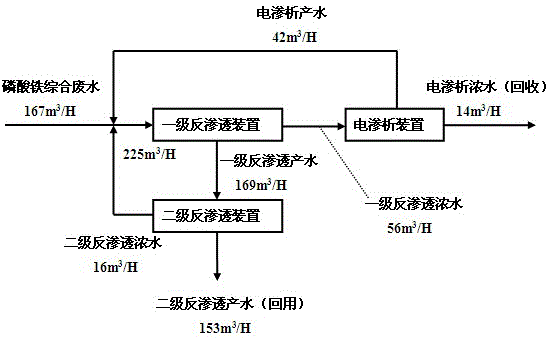

[0026] 4008m for a new energy company with an annual output of 10,000 tons of iron phosphate project 3 / D Ferric Phosphate Comprehensive Wastewater Resource Treatment Project

[0027] 1. Design water quality and quantity

[0028] (1) Design influent water quality and water quantity

[0029]

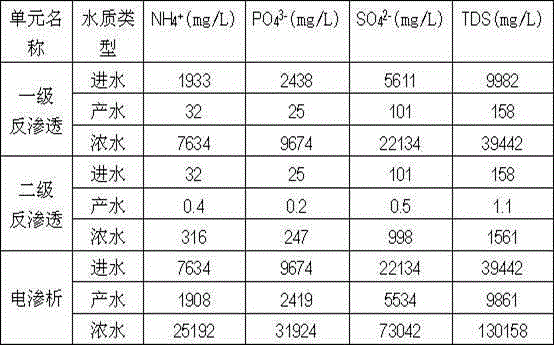

[0030] Convert to NH 4 + with PO 4 3- see table below

[0031] project NH 4 + (mg / L) PO 4 3- (mg / L) SO 4 2- (mg / L) pH Water temperature (℃) Ferric phosphate comprehensive wastewater 1933 2438 5611 2.3 25

[0032] The volume of iron phosphate comprehensive wastewater is 4008m 3 / D (167m 3 / H).

[0033] (2) Water quality and quantity for producing pure water

[0034] The water quality requirements for the production of pure water should reach conductivity ≤ 10μS / cm, TDS ≤ 4mg / L, and the production volume of pure water ≥ 3672m 3 / D (153m 3 / H).

[0035] (4) Water quality and quantity of recovered concentrated water

[0036] R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com