Preparation method of active carbon composite material capable of magnetic separation in liquid

A composite material, activated carbon technology, applied in solid separation, magnetic separation, chemical instruments and methods, etc., can solve the problems of screen blockage, activated carbon loss, separation difficulty, etc., to reduce load, improve adsorption performance, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

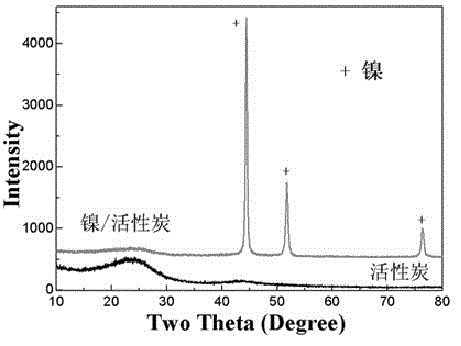

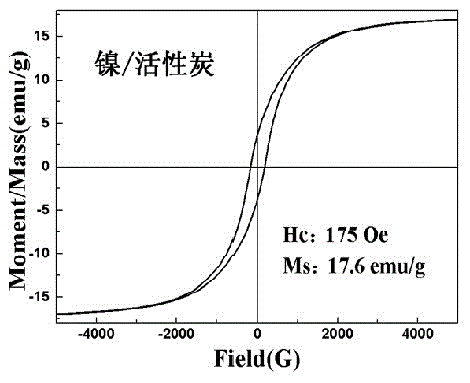

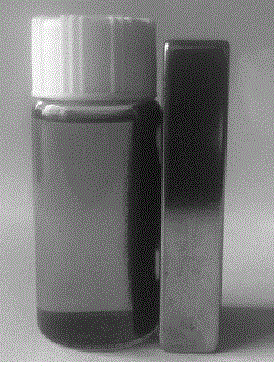

[0008] Specific embodiment 1: first activated carbon is pulverized into activated carbon granules, and after utilizing 200 mesh sieves to screen; Adopt strong alkali (sodium hydroxide, potassium hydroxide etc.) to carry out surface modification to activated carbon granules under heating condition, fully wash (pH = 7) and dry. Take 4 parts of activated carbon, 1 part of nickel chloride and 4 parts of CTAB (cetyltrimethylammonium bromide) and dissolve them in a mixed solution of 20 parts of deionized water and 15 parts of alcohol, and stir magnetically for 12 hours. Then add 4 parts of N dropwise 2 h 4 ·H 2 O (hydrazine hydrate) as a reducing agent, stirred for 40 min to form a stable Ni(OH) 2 microemulsion, and then transplant the above solution into a polytetrafluoroethylene-lined reactor, and conduct hydrothermal treatment at a constant temperature of 150° C. for 6 hours. After magnetic separation (the magnetic field on the surface of the magnet is about 2000G), washing (...

specific Embodiment approach 2

[0009] Specific embodiment 2: first activated carbon is pulverized into activated carbon granules, and after utilizing 200 mesh sieves to screen; Adopt strong alkali (sodium hydroxide, potassium hydroxide etc.) to carry out surface modification to activated carbon granules under heating condition, fully wash (pH = 7) and dry. Take 4 parts of activated carbon and 2 parts of nickel sulfate and dissolve them in a mixed solution of 20 parts of deionized water and 20 parts of alcohol, and stir magnetically for 12 hours; while stirring, add 6 parts of N 2 h 4 ·H 2 O (hydrazine hydrate), after stirring for 30 minutes, put it in a kettle, heat it in constant temperature water at 130 ° C for 2 hours, after magnetic separation, wash it with deionized water and absolute ethanol until neutral, and under the protection of 3% argon-hydrogen mixed gas, Heat treatment at 180°C for 4 hours to obtain a magnetically separable activated carbon composite material supported by ferromagnetic nicke...

specific Embodiment approach 3

[0010] Specific embodiment 3: first activated carbon is pulverized into activated carbon particles, and after utilizing 200 mesh sieves to screen; adopt strong alkali (sodium hydroxide, potassium hydroxide etc.) to carry out surface modification to activated carbon particles under heating condition, fully wash (pH = 7) and dry. Take 4 parts of activated carbon, 1 part of nickel nitrate and 4 parts of CTAB (cetyltrimethylammonium bromide) and dissolve them in a mixed solution of 20 parts of deionized water and 15 parts of alcohol, and stir magnetically for 12 hours. Then add 4 parts of N dropwise 2 h 4 ·H 2 O (hydrazine hydrate) as a reducing agent, stirred for 60 min to form a stable Ni(OH) 2 microemulsion, and then transplant the above solution into a polytetrafluoroethylene-lined reactor, and conduct hydrothermal treatment at a constant temperature of 120° C. for 6 hours. After magnetic separation, washing and drying, under the protection of 3% argon-hydrogen mixed gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com