Spiral or helical counterflow heat exchanger

A technology of heat exchangers and exchangers, applied in the direction of indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problem that flat and corrugated double-sided enamelled steel plates are not suitable for partition walls, and cannot be spiral or Helical winding and other problems to achieve the effects of simplified production, low cost, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

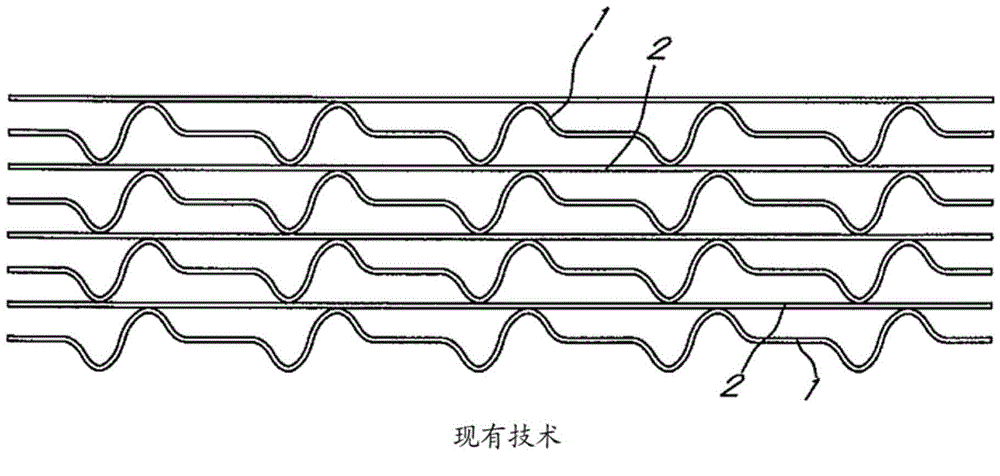

[0046] figure 1 Schematically shows a cross-section of a plurality of corrugated double-sided enamelled steel sheets, used in prior art housings for regenerative heat exchangers. In this case, cold-rolled corrugated steel sheets 1 painted on both sides alternate with flat double-sided enamelled steel sheets 2 .

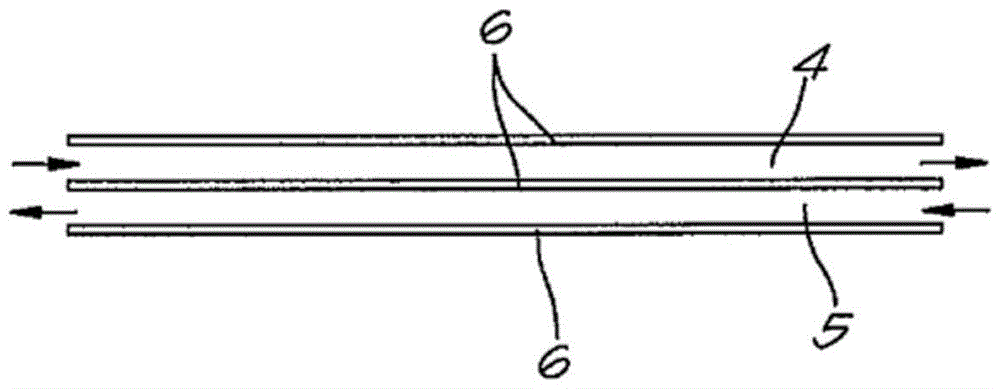

[0047] figure 2 Schematically shows a cross-section of the simplest counterflow heat exchanger 3 according to the invention, comprising two chambers 4, 5 separated from each other by a flat thin double-sided enamelled steel plate 6, at two different temperatures Fluid flows through the two chambers 4, 5 in opposite directions.

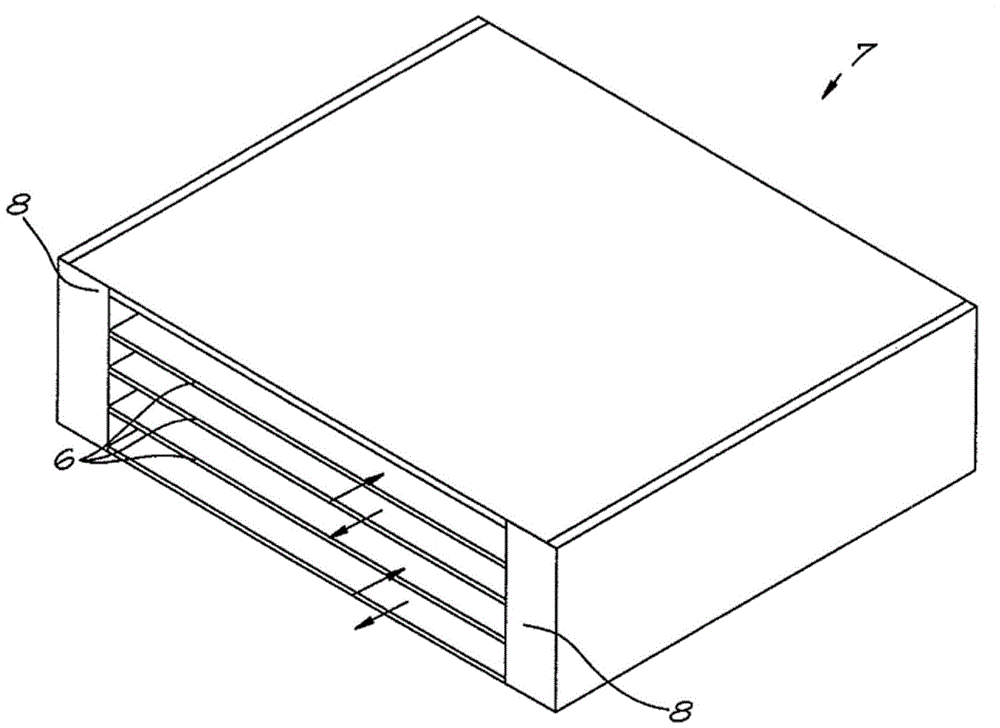

[0048] image 3 A perspective view is schematically shown of a counterflow heat exchanger 7 comprising a stack of flat double-sided enamelled steel sheets 6 , the edges of which are held on corrosion-resistant partitions 8 .

[0049] Figure 4 show image 3 variant, whereby a stack of flat double-sided enamelled steel sheets 6 is separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com