Preparation method of a transparent and fast-response flexible electrochromic film

A fast-response, flexible electrical technology, applied in the plating of superimposed layers, ion implantation plating, coating, etc., can solve the problems of harsh test conditions, fractured substrate, separation, etc., to achieve short response time, wide discoloration range, Strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

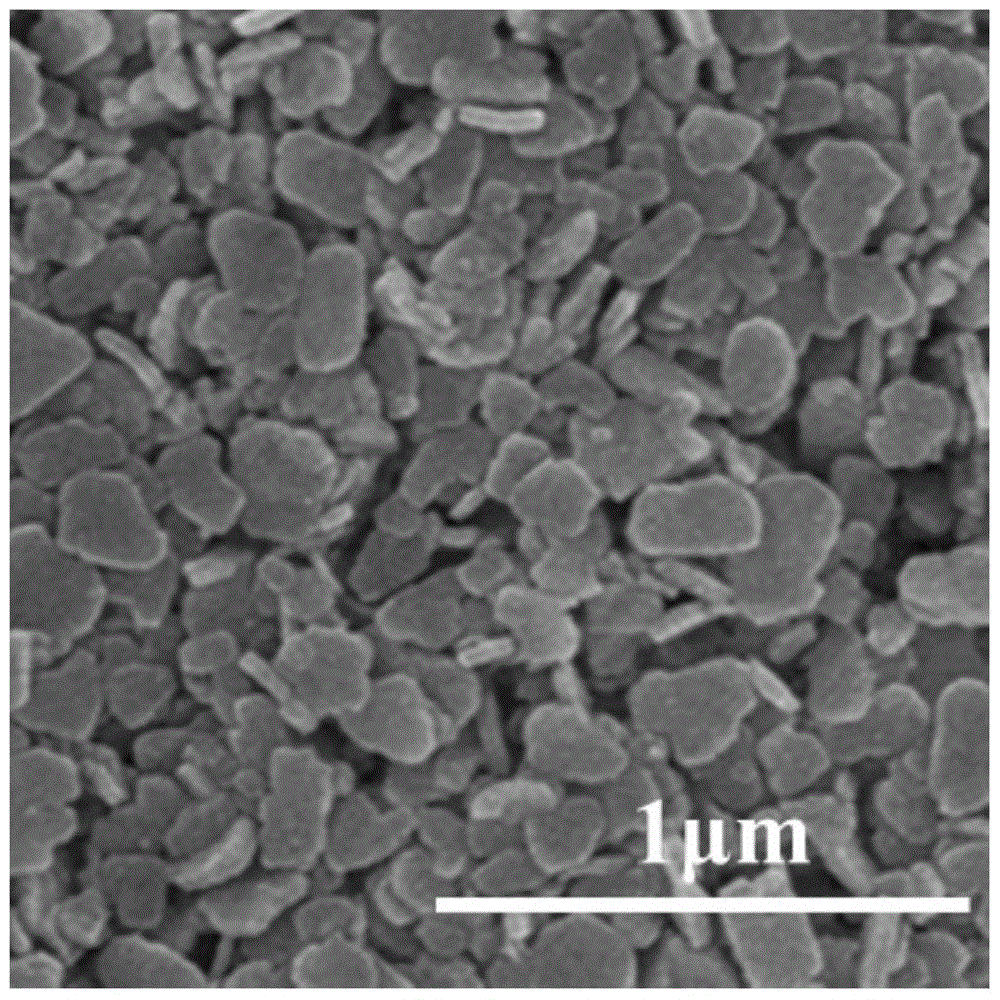

[0036] Specific Embodiment 1: This embodiment is based on the preparation method of a transparent fast-response flexible electrochromic film is completed according to the following steps:

[0037] 1. Ultrasonically clean the flexible substrate in acetone, methanol and ultrapure water for 20-30 minutes respectively, and then dry it at a temperature of 40°C-60°C for 10h-15h to obtain a clean flexible substrate;

[0038]The flexible substrate described in step 1 is a PET substrate covered with EVA glue with a thickness of 20nm to 100nm;

[0039] 2. Prepare the Ag layer: Sputter an Ag deposition layer with a thickness of 10nm to 50nm on the surface of the EVA glue on a clean flexible substrate by magnetron sputtering to obtain a PET substrate with an Ag layer deposited on the surface;

[0040] The parameters of the magnetron sputtering method described in step 2 are as follows: the target material is an Ag target, the sputtering type is DC sputtering, the target-base distance is 1...

specific Embodiment approach 2

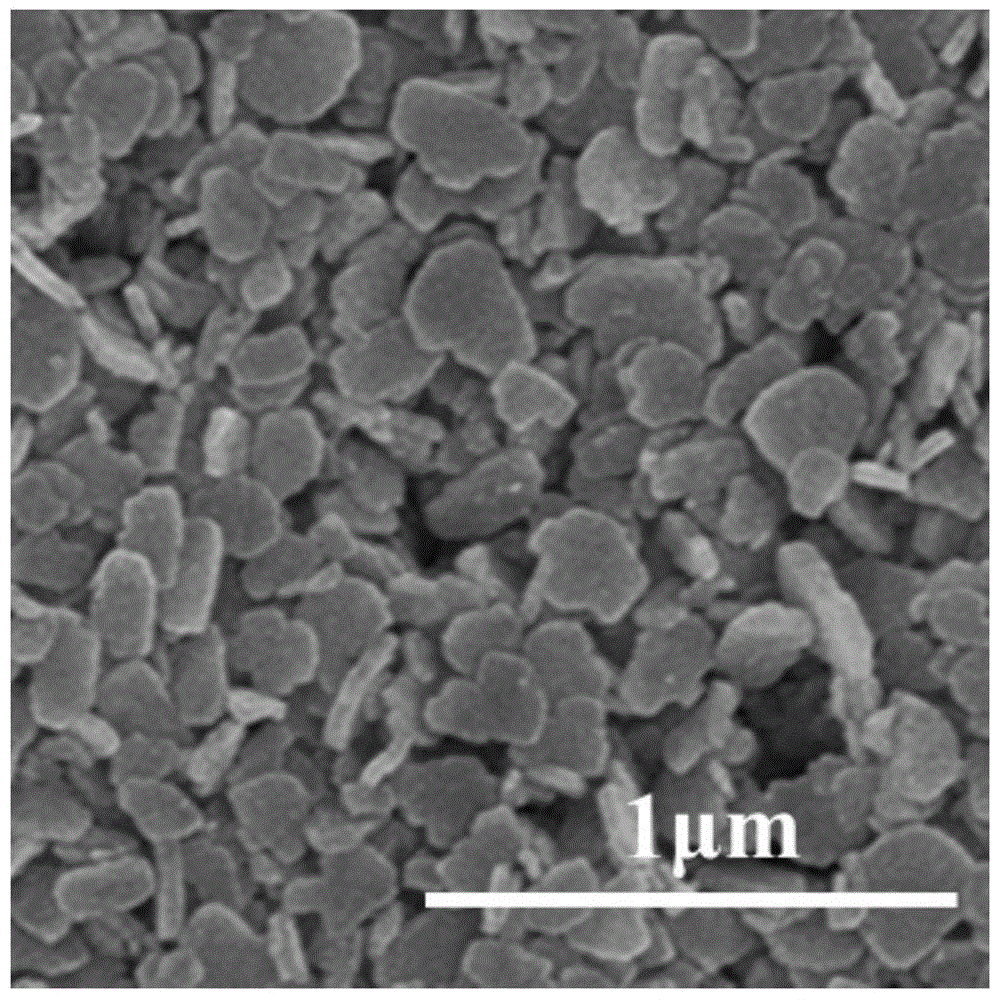

[0061] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the parameters of the magnetron sputtering method described in step 2 are as follows: the target material is an Ag target, the sputtering type is DC sputtering, and the target-based The distance is 15 cm, the gas flow is 5 sccm of argon, the deposition temperature is room temperature, the deposition pressure is 2 Pa, the sputtering power is 20 W, and the deposition time is 40 s. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0062] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the parameters of the magnetron sputtering method described in step 2 are as follows: the target material is an Ag target, and the sputtering type is DC sputtering , the target-base distance is 15cm, the gas flow rate is 5sccm argon, the deposition temperature is room temperature, the deposition pressure is 3Pa, the sputtering power is 20W, and the deposition time is 40s. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com