Pressure-bearing plugging agent for offshore drilling fluid and application method thereof

A technology of marine drilling and plugging agent, applied in the field of temporary plugging agent, can solve the problems of oil and gas layer pollution, drilling fluid loss, etc., and achieve the effects of good viscosity improvement, anti-permeability performance, and excellent shear dilution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

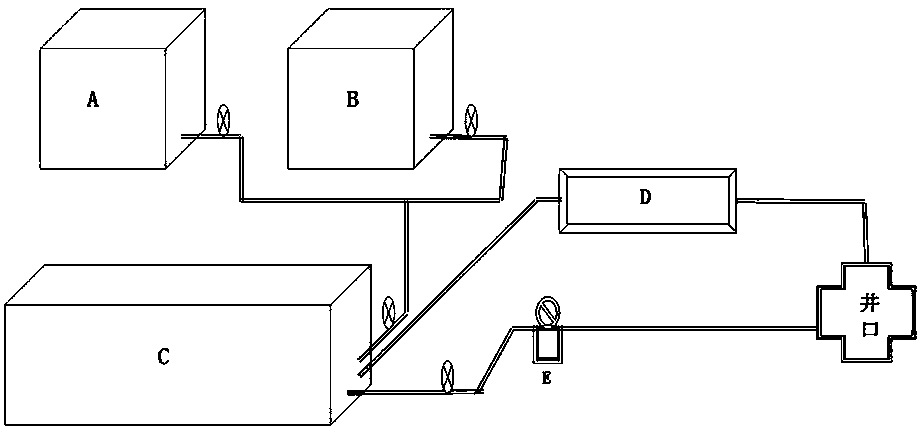

Image

Examples

Embodiment 1

[0024] A pressure-bearing plugging agent for marine drilling fluid, which consists of the following components: 1500g of aluminum ore powder, 1000g of sodium soil, 2500g of fly ash, 2500g of wood fiber powder, 1000g of composite salt-resistant polymer, 1500g of furfural slag powder, The joint agent is 100g; after stirring for 40 minutes, it is the finished product.

Embodiment 2

[0026] A pressure-bearing plugging agent for marine drilling fluid, which consists of the following components: 1000g of aluminum ore powder, 2000g of sodium soil, 2500g of fly ash, 2000g of wood fiber powder, 1000g of composite salt-resistant polymer, 1500g of furfural slag powder, The joint agent is 100g; after stirring for 40 minutes, it is the finished product.

Embodiment 3

[0028] A pressure-bearing plugging agent for marine drilling fluid, which consists of the following components: 1000g of aluminum ore powder, 1000g of sodium soil, 2500g of fly ash, 2500g of wood fiber powder, 1000g of composite salt-resistant polymer, 1000g of furfural slag powder, The joint agent is 100g; after stirring for 40 minutes, it is the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com