A method for producing ferrite pre-sintered material by using steelmaking dry dust removal fine ash

A technology for ferrite pre-sintered material and dry dust removal, which is applied in the field of producing ferrite pre-sintered material by using steel-making dry dust removal fine ash, can solve the problems of difficulty in utilization, low added value, aggravated environmental pollution, etc. The effect of low cost, simple process and rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

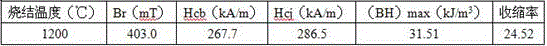

Image

Examples

Embodiment 1

[0023] Embodiment 1: Utilize the method for preparing ferrite pre-sintered material by using steelmaking dedusting fine ash, the specific process steps are:

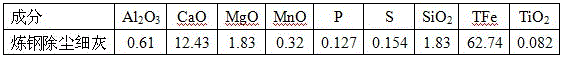

[0024] (1) Select 10kg of steelmaking dust removal fine ash, the chemical composition of steelmaking dust removal fine ash is shown in Table 1:

[0025] Table 1 Main chemical composition of steelmaking dust removal fine ash (%)

[0026]

[0027] Carry out ball milling in ball mill for 24h, and sieve with vibrating sieve, particle size D 50 =8.46µm.

[0028] (2) Slurry, stir and disperse the screened dedusted fine ash with tap water. The mass ratio of the amount of water added to the raw material of fine ash is 1.4:1. After stirring, the slurry is magnetically separated by a magnetic separator with a magnetic induction of 0.08T .

[0029] (3) Granulate the dust-removed fine ash after the above magnetic separation in a spray dryer, the air inlet temperature is 210°C, the speed of the peristaltic pump is 60mL / h, and t...

Embodiment 2

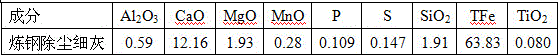

[0038] (1) Select 10kg of steelmaking dust removal fine ash, the chemical composition of steelmaking dust removal fine ash is shown in Table 4:

[0039] Table 4 Main chemical composition of steelmaking dust removal fine ash (%)

[0040]

[0041] Carry out ball milling in ball mill for 24h, and sieve with vibrating sieve, particle size D 50 =9.15µm.

[0042] (2) Slurry, stir and disperse the screened dedusted fine ash with tap water. The mass ratio of the amount of water added to the fine ash raw material is 1.8:1. After stirring, the slurry is magnetically separated by a magnetic separator with a magnetic induction of 0.1T .

[0043] (3) Granulate the dust-removed fine ash after the above magnetic separation in a spray dryer, the air inlet temperature is 230°C, the speed of the peristaltic pump is 65mL / h, and the rotation frequency of the fan is 55H Z .

[0044] (4) The above-mentioned dry and granulated materials were roasted and oxidized in a carbon tube furnace, the ma...

Embodiment 3

[0052] (1) Select 10kg of steelmaking dust removal fine ash, the chemical composition of steelmaking dust removal fine ash is shown in Table 7:

[0053] Table 7 Main chemical composition of steelmaking dust removal fine ash (%)

[0054]

[0055] Ball milling in a ball mill for 24 hours, and sieving with a vibrating sieve, particle size D 50 =9.58µm.

[0056] (2) Slurry, stir and disperse the screened dedusted fine ash with tap water. The mass ratio of the amount of water added to the raw material of fine ash is 1.1:1. After stirring, the slurry is magnetically separated by a magnetic separator with a magnetic induction of 0.05T .

[0057] (3) The above-mentioned dust-removed fine ash after magnetic separation is granulated in a spray dryer, the air inlet temperature is 200°C, the rotation speed of the peristaltic pump is 50mL / h, and the rotation frequency of the fan is 48Hz.

[0058] (4) Roast and oxidize the dry and granulated dust removal fine ash in a carbon tube furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com