Novel probe body and machining method thereof

A processing method and probe body tube technology, applied in the direction of instruments, measuring heat, measuring devices, etc., can solve the problem that it is difficult to ensure the perpendicularity between the columnar body and the base of the probe body, the probe body is difficult to meet the design parameter requirements, and the influence of the probe Body tube stability and other issues, to achieve the effect of good processing effect, good angle requirements, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

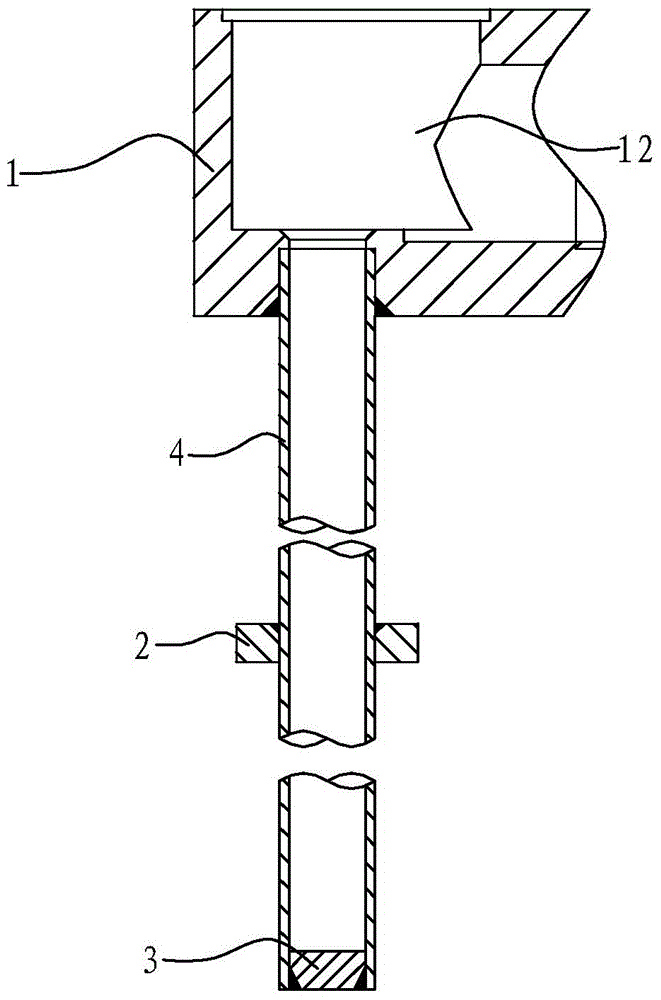

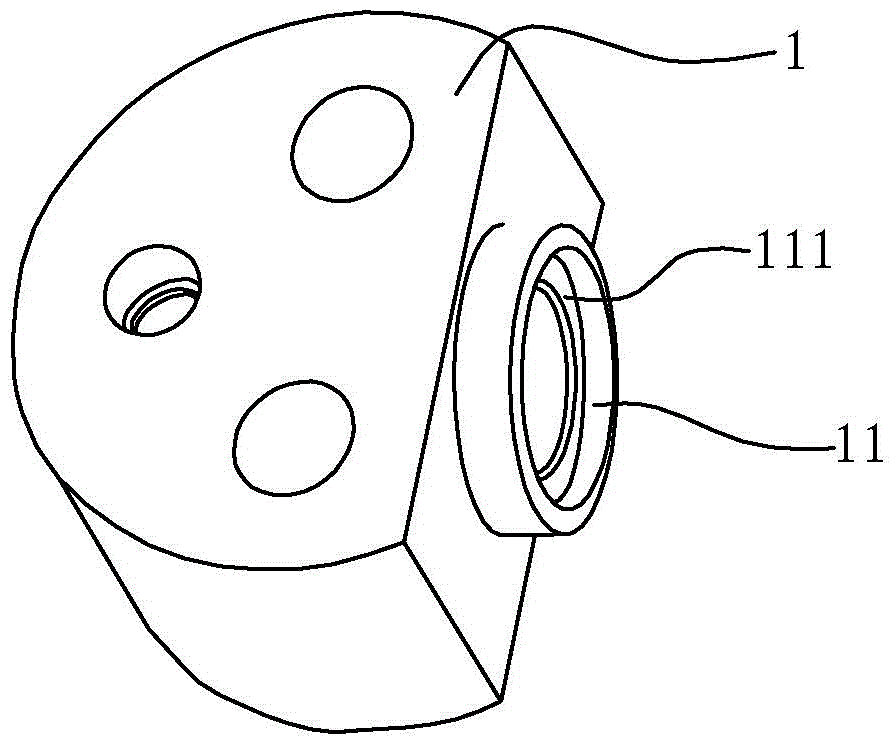

[0028] Such as Figure 1 to Figure 6 As shown, the novel probe body in this embodiment includes a probe body base 1 , a probe body tube 4 , a step body 2 and a plug 3 .

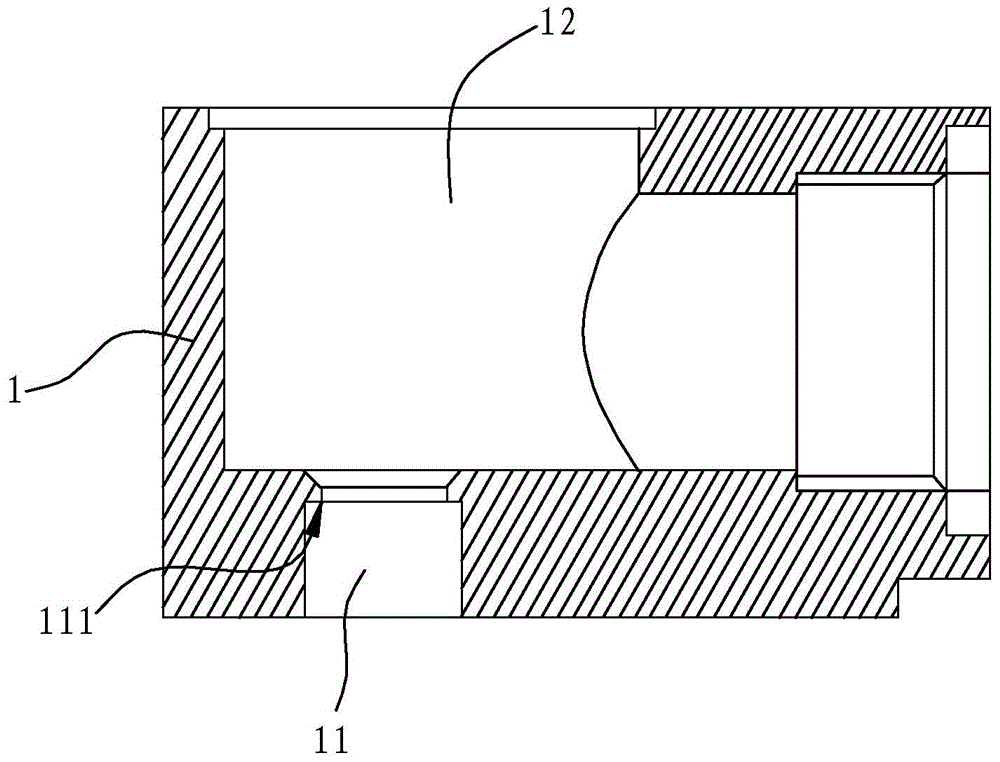

[0029] The probe body base 1 has an accommodating cavity 12 , and the probe body base 1 is also provided with a mounting hole 11 communicating with the accommodating cavity 12 , and the peripheral wall at the inner end of the mounting hole 11 has an inner shoulder 111 .

[0030] The probe body tube 4 is a hollow tube with an axial through hole, the first end of the probe body tube 4 is installed in the installation hole 11 by sealing welding, and the first end of the probe body tube 4 is against the inner The installation position of the probe body tube 4 in the installation hole 11 is limited on the shoulder 111, so as to ensure that the length of the probe body tube 4 left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com