Film casting liquid for PVDF flat membrane and preparing method for PVDF flat membrane

A technology of casting liquid and flat film, applied in the field of water treatment, can solve the problems of low surface strength, scratched hard particles, easy to be scratched, etc., and achieve the effect of high surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

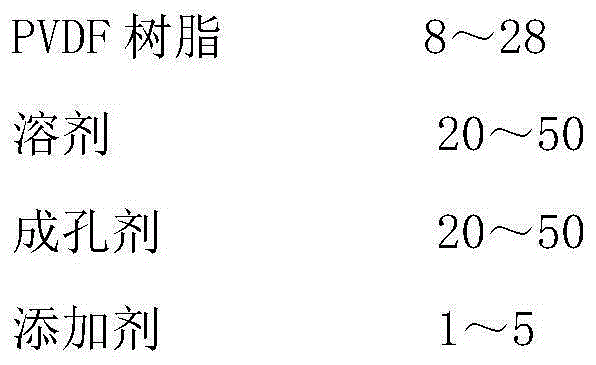

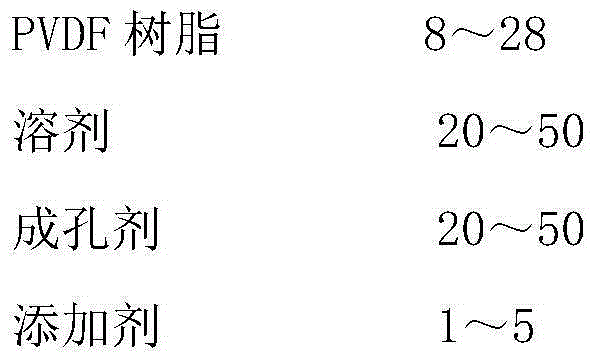

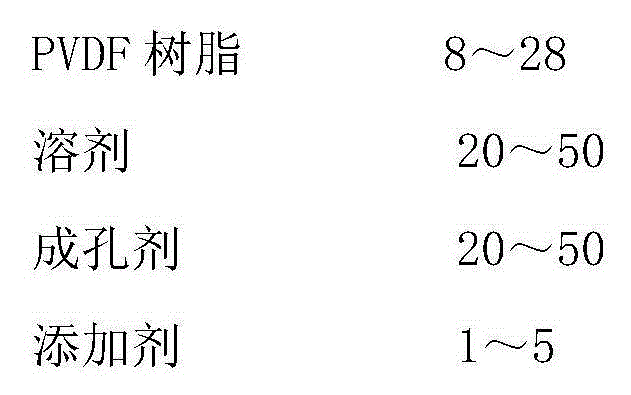

Method used

Image

Examples

Embodiment 1

[0030] PVDF resin: solvent: pore-forming agent: additive is 20:35:40:5, stirred and mixed at 110 degrees Celsius to form a uniform casting solution, in which the solvent is dimethylacetamide, and the pore-forming agent is diethylene diacetate Alcohol monomethyl ether, the additive is a mixture of polyethylene glycol and polyvinylpyrrolidone with a weight ratio of 2:3.

[0031] Cool the casting solution to 80 degrees and degas for 6 hours, scrape it evenly on the PET non-woven fabric, and cool it at room temperature for 2 minutes, so that the surface temperature of the casting solution is less than 40 degrees, then put it in distilled water and wash it for 10 minutes before taking it out The temperature of the distilled water is 29 degrees Celsius, the pore diameter of the flat membrane is measured to be 0.03 micron, and the pure water flux under 1BAR pressure is 800LMH. After being rinsed with pure water for 60 minutes under 6BAR, the surface of the membrane was as good as new...

Embodiment 2

[0033] PVDF resin: solvent: pore forming agent: additive is 18:42:35:5, stirred and mixed at 100 degrees Celsius to form a uniform casting solution, in which the solvent is dimethylacetamide and dimethylformamide by weight The mixture with a ratio of 22:20, the pore forming agent is a mixture of diethylene glycol monomethyl ether and ethylene glycol monomethyl ether with a weight ratio of 20:15, and the additive is polyethylene glycol and polyvinylpyrrolidone with a weight ratio of 1:4 mixture.

[0034] Cool the casting solution to 60 degrees and degas it for 6 hours, scrape it evenly on the PET non-woven fabric, and cool it at room temperature for 2 minutes to make its surface temperature less than 30 degrees Celsius, then put it in distilled water and wash it for 10 minutes before taking it out. A PVDF flat membrane with uniform surface was obtained, the temperature of distilled water was 19 degrees Celsius, the pore diameter of the flat membrane was determined to be 0.05 mi...

Embodiment 3

[0036]PVDF resin: solvent: pore-forming agent: the ratio of additives is 8:45:45:2, stir and mix at 80 degrees Celsius to form a uniform casting solution, in which the solvent is dimethylformamide, and the pore-forming agent is ethylene glycol Alcohol monomethyl ether, the additive is polyethylene glycol.

[0037] Cool the casting solution to 40 degrees and degas it for 6 hours, scrape it evenly on the PET non-woven fabric, cool it at room temperature for 2 minutes, so that its surface temperature is less than 20 degrees Celsius, then put it in distilled water and wash it for 10 minutes before taking it out. Obtain a PVDF flat membrane with a uniform surface, the temperature of distilled water is 9 degrees Celsius, the pore diameter of the flat membrane is measured to be 0.1 micron, and the pure water flux under 1BAR pressure is 4000LMH. After being rinsed with pure water for 60 minutes under 6BAR, the surface of the membrane was as good as new without any damage, showing very...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com