Lithium titanate composite material and preparation method thereof

A composite material, lithium titanate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low electronic conductivity of lithium titanate, difficulty in processing lithium titanate powder, and high cost of preparation process, and achieves easy processing. The effect of sieve, low production cost and high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A preparation method for a lithium titanate composite material, comprising the steps of:

[0069] (1) According to the stoichiometric ratio of Li:Ti=0.816:1, Ti:Al=4.94:0.06 and C:Ti=0.088:1, 620g lithium carbonate, 1588g titanium dioxide, 90g aluminum nitrate nonahydrate, lemon monohydrate Mix 400g of acid and 1600mL of deionized water, and ball mill for 3 hours to form a uniform slurry with good fluidity;

[0070] (2) Dry the slurry under ventilated conditions at 100-130°C, and crush the dried block for 5 minutes to obtain a precursor; the precursor is a white powder;

[0071] (3) Under the protection of an inert atmosphere, the precursor powder was calcined at 800°C for 6 hours and pulverized for 2 minutes to obtain Particle A;

[0072](4) Under the protection of an inert atmosphere, calcinate the particle A at 750°C for 3 hours, and pulverize it for 1 minute.

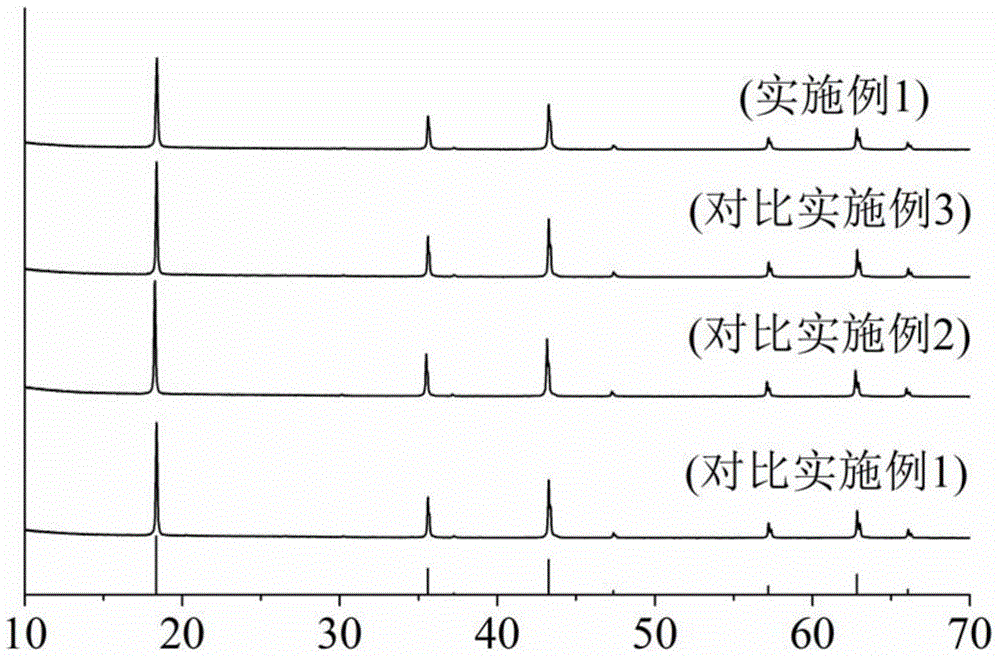

[0073] The lithium titanate composite material prepared by this preparation method is designated as samp...

Embodiment 2

[0092] A preparation method of a lithium titanate composite material, which includes steps (1) to (4); the steps (2) to (4) are the same as in Example 1, and the step (1) is: according to Li:Ti=0.832:1 , Ti:Al=4.94:0.06 and C:Ti is the stoichiometric ratio of 0.088:1, lithium carbonate 632g, titanium dioxide 1588g, aluminum nitrate nonahydrate 90g, citric acid monohydrate 400g and deionized water 1600mL are mixed, ball milled for 3 hours, a uniform slurry with good fluidity is formed; after step (4), the lithium titanate composite material is obtained.

[0093] The lithium titanate composite material prepared by this preparation method is designated as sample 2. After testing, sample 2 is mainly Li 4 Ti 4.94 Al 0.06 o 12 / nano-carbon composite material, but its pH value is slightly higher than 11.7, and its 0.1C reversible capacity is 159.1mAh / g (the first efficiency is 93.3%), as shown in Table 4.

Embodiment 3

[0103] A preparation method of a lithium titanate composite material, which includes steps (1) to (4); the steps (2) to (4) are the same as in Example 1, and the step (1) is: according to Li:Ti=0.816:1 , Ti:Al=4.94:0.06 and C:Ti is the stoichiometric ratio of 0.018:1, lithium carbonate 620g, titanium dioxide 1588g, aluminum nitrate nonahydrate 90g, citric acid monohydrate 80g and deionized water 1600mL are mixed, ball milled for 3 hours, a uniform slurry with good fluidity is formed; after step (4), the lithium titanate composite material is obtained.

[0104] The lithium titanate composite material prepared by this preparation method is designated as sample 3. After testing, sample 3 is Li 4 Ti 4.94 Al 0.06 o 12 / Nano-carbon composite material, the XRD spectrum does not appear impurity phase, the electronic conductivity of the powder is 0.36S / m, and its 0.1C reversible capacity is 156.4mAh / g (the first efficiency is 96.2%), as shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com