A kind of preparation method of helical asymmetric supercapacitor

A supercapacitor, helix-shaped technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of complex manufacturing process and difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

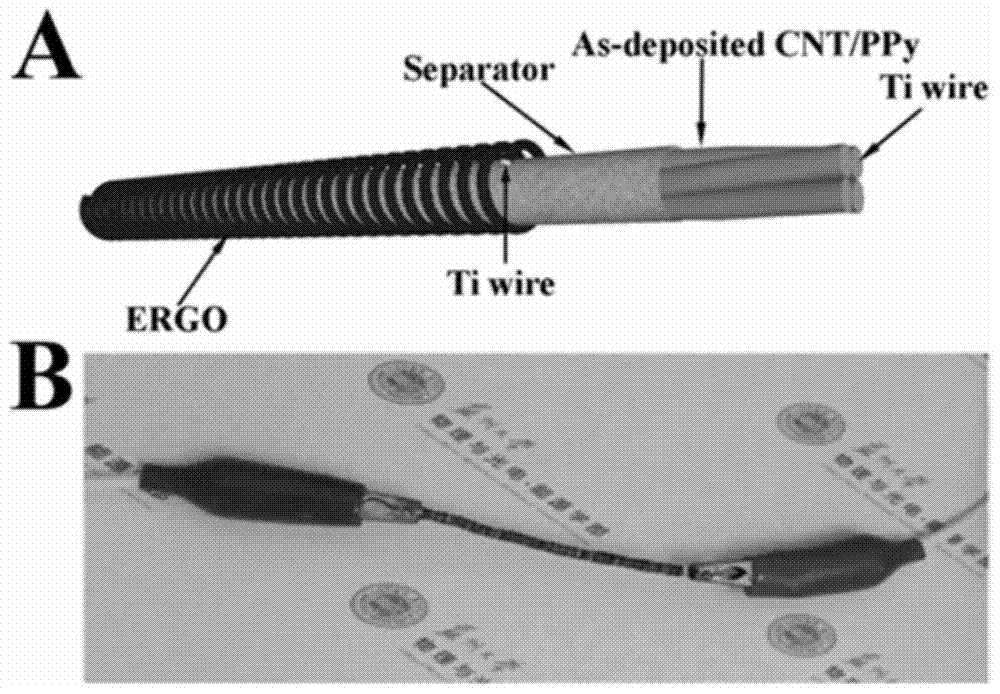

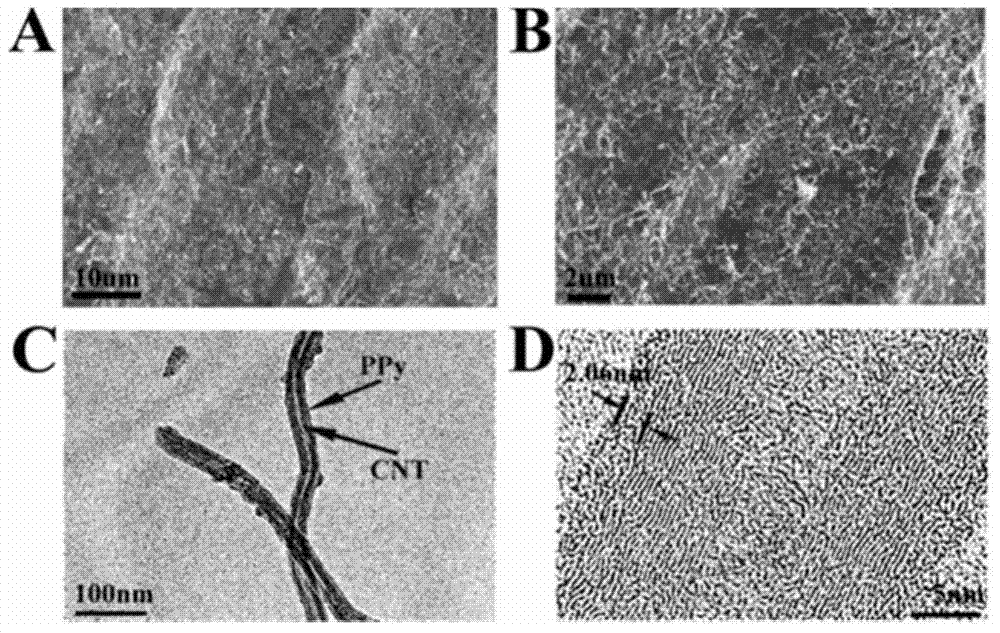

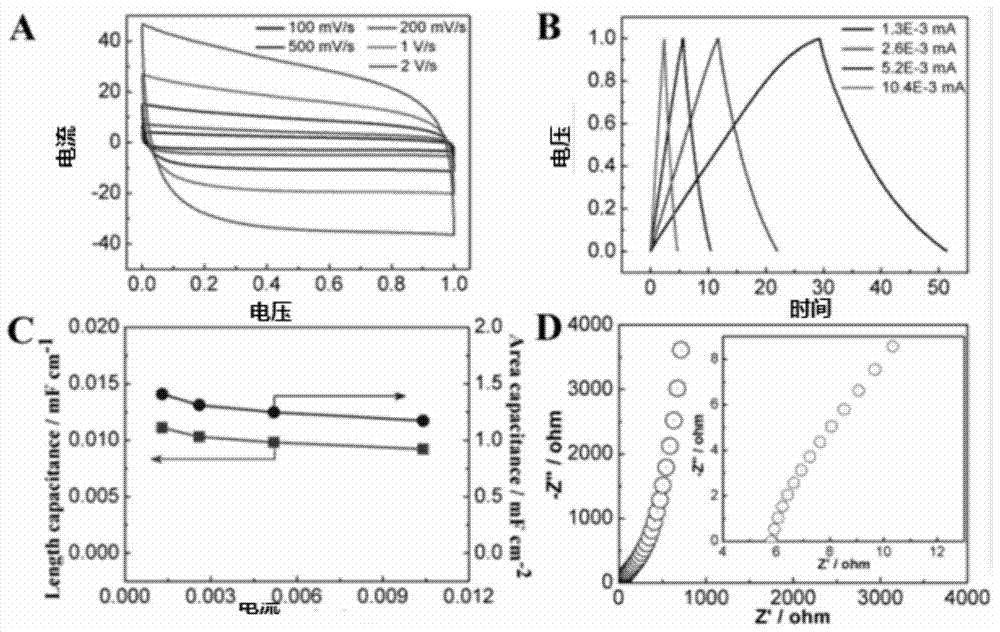

[0030] A method for preparing a helical asymmetric supercapacitor of the present invention comprises the following steps: (a) preparation of a positive electrode (1) dissolving the purchased titanium wire in acetone, 5% dilute hydrochloric acid solution, deionized water and Ultrasonic treatment in absolute ethanol for 30-60min to clean; (2) take 100ml of deionized water, add 100-200mg of carbon nanotubes and ultrasonically for 30-60min to obtain a mixed solution; (3) in the obtained carbon nanotubes Add pyrrole monomer and FeCl to the suspension 2 , slowly drop 5ml of H in 20min 2 o 2 In situ polymerization with rapid agitation. (4) Put the titanium wire into the solution as the base of the positive electrode, and the carbon paper as the negative electrode, and carry out electrophoretic deposition at a DC voltage of 5V for a period of time. (b) preparation of negative electrode material (1) adopt improved Hummer method to oxidize natural graphite powder and make graphene ox...

Embodiment 1

[0034] The present embodiment provides a method for preparing a helical asymmetric supercapacitor, which comprises the following steps:

[0035] (a) Clean the purchased titanium wire by ultrasonic treatment for 30-60min in acetone, 5% dilute hydrochloric acid solution, deionized water and absolute ethanol respectively; take 100ml of deionized water and add 200mg of carbon nanotubes Ultrasound for 60min to obtain the mixed solution; add 0.1g pyrrole monomer and 0.01g FeCl to the obtained carbon nanotube suspension 2 , slowly drop 5ml of H in 20min 2 o 2 The in-situ polymerization reaction was carried out under rapid agitation. The titanium wire was put into the solution as the base of the positive electrode, and the carbon paper was used as the negative electrode, and the electrophoretic deposition was carried out at a DC voltage of 5V for 30min. (b) Using the improved Hummer method to oxidize natural graphite powder to obtain graphene oxide; the graphene oxide solution was ...

Embodiment 2

[0037] The present embodiment provides a method for preparing a helical asymmetric supercapacitor, which comprises the following steps:

[0038] (a) Clean the purchased titanium wire by ultrasonic treatment for 30-60min in acetone, 5% dilute hydrochloric acid solution, deionized water and absolute ethanol respectively; take 100ml of deionized water and add 100mg of carbon nanotubes Ultrasound for 60min to obtain the mixed solution; add 0.1g pyrrole monomer and 0.01g FeCl to the obtained carbon nanotube suspension 2 , slowly drop 5ml of H in 20min 2 o 2 The in-situ polymerization reaction was carried out under rapid agitation. The titanium wire was put into the solution as the base of the positive electrode, and the carbon paper was used as the negative electrode, and the electrophoretic deposition was carried out at 5V DC voltage for 60min. (b) Using the improved Hummer method to oxidize natural graphite powder to prepare graphene oxide; the graphene oxide solution was made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com