Sinking device and method for well point drawdown pipe of liquid soil layer

A downwater pipe and well point technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of low efficiency of well point downpipe settlement and failure of well point downpipe settlement, etc., and achieves rapid settling, convenient operation and practicality , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Settling device for well point downpipe in fluid soil layer.

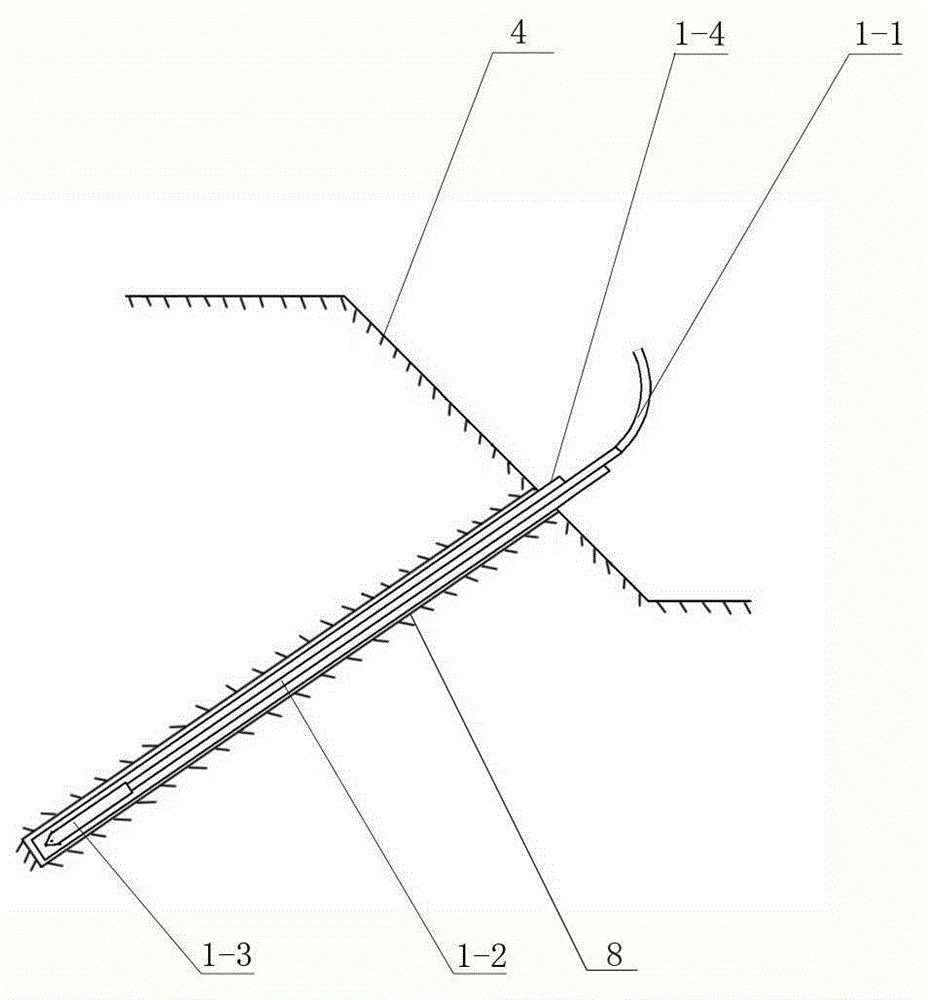

[0031] Such as figure 1 with Image 6 As shown, the settling device of the present invention includes a punching device and a pipe-burying device. The punching device and the buried pipe device are all used in conjunction with the well point downwater pipe 5, and its size is all matched with the size specification of the well point downwater pipe 5. The punching device includes a punching gun 1-2, the rear end of the punching gun 1-2 is connected with a water belt 1-1, the other end of the water belt 1-1 is connected with a high-pressure water pump, and the front end of the punching gun 1-2 is equipped with a punching gun The head 1-3, the front end of the punching gun head 1-3 is tapered, which facilitates the insertion of the punching gun 1-2 in the well hole 8. The outside of the punching gun 1-2 is covered with a casing pipe 1-4. One end of the casing tube 1-4 near the surface of the ba...

Embodiment 2

[0034] Embodiment 2: The settlement method of the well point downwater pipe in the fluid soil layer.

[0035] The settling method of the present invention adopts the settling device described in embodiment 1, and the specific steps of the settling method are:

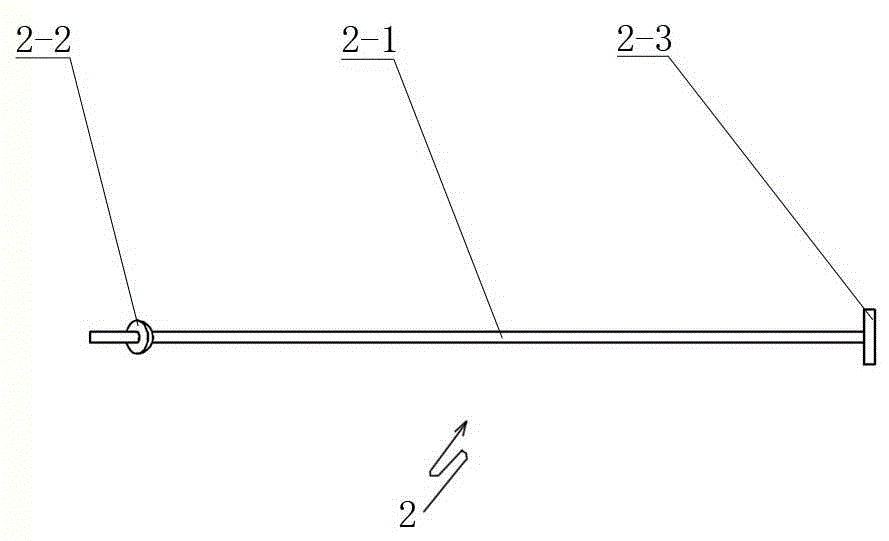

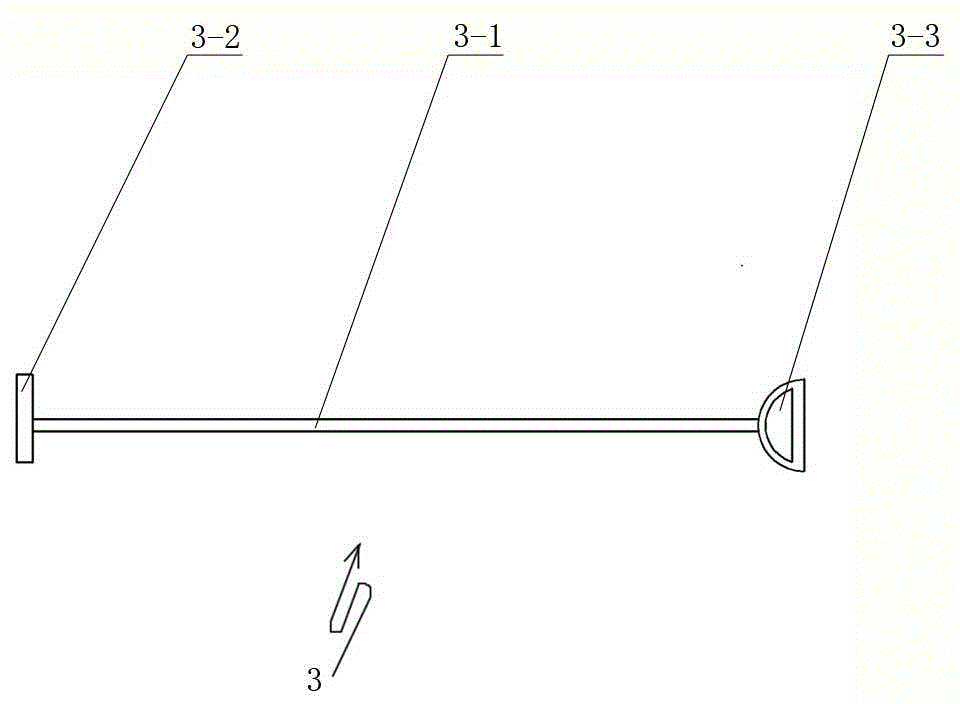

[0036] (1) if figure 1 , figure 2 , image 3 , Figure 4 with Figure 7 Shown, make matching casing pipe 1-4, punching gun 1-2, push rod 2 and push plate 3 according to the size specification of the well point downcomer 5 to be set. Its dimensional coordination has been briefly explained in Embodiment 1, that is: the inner diameter of the protective tube 1-4 is greater than the outer diameter of the punch head 1-3 gun body, and the outer diameter of the protective tube 1-4 is equal to the pre-designed The inner diameter of a good well hole 8; the diameter of the connecting rod 2-1 is less than the inner diameter of the well point downwater pipe 5; the contact surface of the push rod head 2-2 and the well point dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com