Carbon fiber wire beam continuous metal electroplating process and carbon fiber wire beam continuous metal electroplating apparatus

A carbon fiber tow, electroplating metal technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve problems such as black core, and achieve the effect of simple method, low energy consumption and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

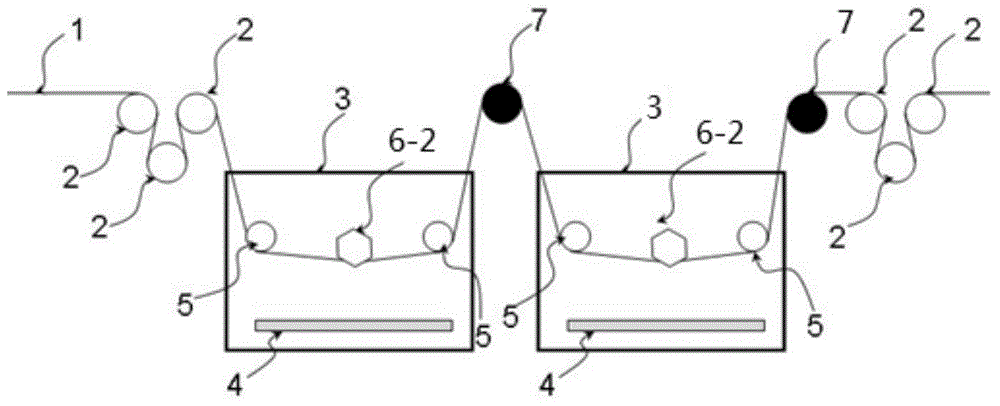

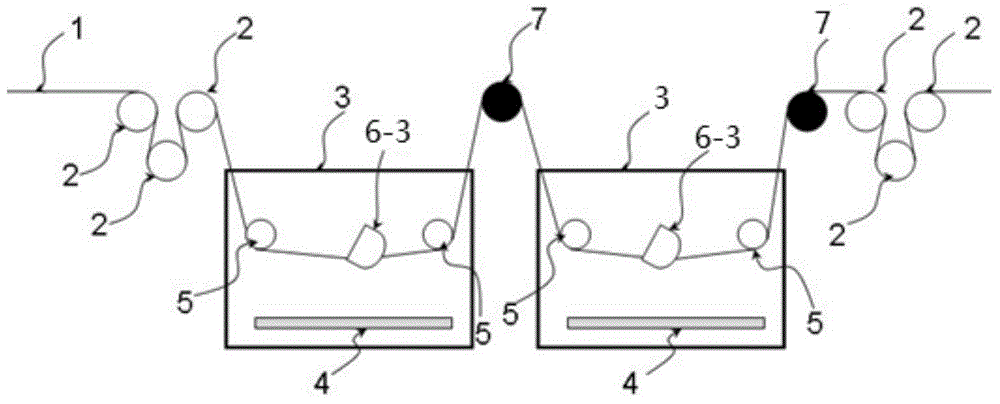

[0044]A carbon fiber tow electroplating device, which includes a transmission guide roller 2, an electroplating tank 3, an anode metal plate 4, a fixed guide roller 5, and a conductive guide roller 7. It is characterized in that there are 2-5 electroplating tanks 3, and the first Above the input end of each electroplating tank 3, there are three transmission guide rollers 2 distributed in a triangle, and an anode metal plate 4 is distributed at the bottom of each electroplating tank 3, and fixed guide rollers 5 are respectively arranged above the two ends of the anode metal plate 4. There is a non-circular guide roller above the middle of the metal plate 4, a conductive guide roller 7 is arranged above between the electroplating tanks 3, a conductive guide roller 7 is arranged above the output end of the last electroplating tank 3, and the last electroplating tank 3 There are three transmission guide rollers 2 that are triangularly distributed behind the upper conductive guide ...

Embodiment 2

[0049] Use non-circular guide rollers as elliptical transmission guide rollers 6-2, the ratio of its major axis to minor axis is 1.2; set 2 electroplating tanks, and set 2 identical elliptical guide rollers in each electroplating tank; the rest The structure of the device is the same as in Example 1. The conductive guide roller 7 is a stainless steel guide roller. The anode metal plate 5 is a Ni plate.

[0050] Polyacrylonitrile (PAN)-based high-strength 24K carbon fiber 1 with a diameter of 7 μm was heat-treated in a desizing furnace at 650 ° C for 5 minutes, and the atmosphere was argon; Sodium aqueous solution cleaning tank for cleaning, and then enter the water washing tank to wash off the residual sodium lauryl sulfate on the surface of the carbon fiber with flowing deionized water. The content of sodium lauryl sulfate in the running water is 0.29g / L; then enter 2 Continuous nickel plating in a plating tank. The formula of the electroplating solution is: NiSO 4 ·6H 2...

Embodiment 3

[0054] The non-circular guide roller is used as an elliptical transmission guide roller 6-1, and the ratio of its major axis to the minor axis is 3.0; 5 electroplating tanks are set, and an elliptical transmission guide roller 6-1 with the same structure is arranged in each electroplating tank 1; All the other device structures are the same as in Embodiment 1. The conductive guide roller 7 is a copper guide roller. The anode metal plate 5 is a Ni plate.

[0055] The polyacrylonitrile-based 24K carbon fiber 1 with a diameter of about 7 μm was heat-treated in a desizing furnace at 700 ° C for 3 minutes, and the atmosphere was argon; next, the carbon fiber tow 1 was washed in an aqueous solution containing 2.0 g / L sodium lauryl sulfate tank for cleaning, and then enter the washing tank to wash off the residual sodium lauryl sulfate on the surface of the carbon fiber with flowing deionized water. The content of sodium lauryl sulfate in the running water is detected to be 0.47g / L;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com