Variable-color heat transfer printing ink and preparation method thereof

A color-changing and ink technology, which is applied in ink, household utensils, applications, etc., can solve the problems of thermal transfer inks such as non-changeable color, unstable connection, easy to fall off, etc., to achieve bright colors, wide range of use, and clarity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

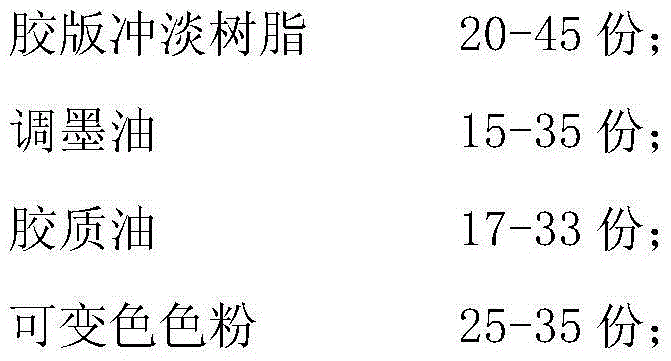

[0027] A color-changing sublimation thermal transfer ink, comprising the following components:

[0028]

[0029] Wherein, the composition and parts by weight of variable color toner are as follows:

[0030]

[0031]

[0032] The preparation method of the above-mentioned color-changing sublimation thermal transfer printing ink, the steps are as follows:

[0033] (1) Dilute the offset resin, varnish, and colloidal oil in sequence according to a certain proportion, and mix and stir in a conventional method;

[0034] (2) Add the above-mentioned stirring solution to the color-changing toner, and mix and stir in a conventional method; and process the above-mentioned mixed mixture with a three-roll mill according to the known technology in the industry to form a color-changing sublimation thermal transfer ink.

Embodiment 2

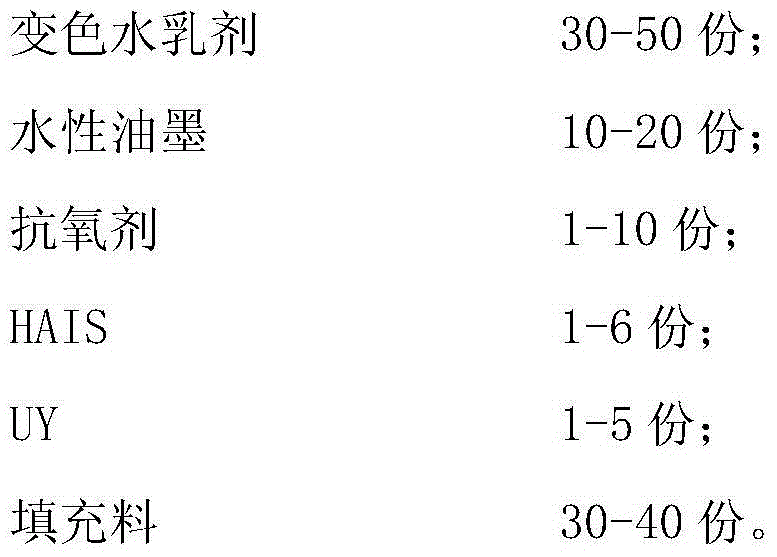

[0036] A color-changing sublimation thermal transfer ink, comprising the following components:

[0037]

[0038] Wherein, the composition and parts by weight of variable color toner are as follows:

[0039]

[0040] The preparation method of the above-mentioned color-changing sublimation thermal transfer printing ink, the steps are as follows:

[0041] (1) Dilute the offset resin, varnish, and colloidal oil in sequence according to a certain proportion, and mix and stir in a conventional method;

[0042] (2) Add the above-mentioned stirring solution to the color-changing toner, and mix and stir in a conventional method; and process the above-mentioned mixed mixture with a three-roll mill according to the known technology in the industry to form a color-changing sublimation thermal transfer ink.

Embodiment 3

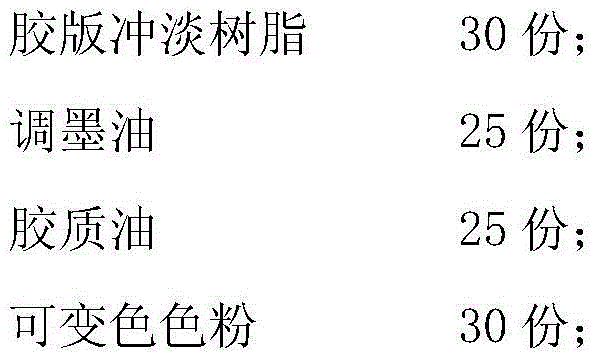

[0044] A color-changing sublimation thermal transfer ink, comprising the following components:

[0045]

[0046] Wherein, the composition and parts by weight of variable color toner are as follows:

[0047]

[0048] The preparation method of the above-mentioned color-changing sublimation thermal transfer printing ink, the steps are as follows:

[0049] (1) Dilute the offset resin, varnish, and colloidal oil in sequence according to a certain proportion, and mix and stir in a conventional method;

[0050] (2) Add the above-mentioned stirring liquid to the color-changing toner, and mix and stir in a conventional method; and process the above-mentioned mixed mixture with a three-roll mill according to the known technology in the industry to form a color-changing sublimation thermal transfer ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com