Erasable neutral ink and preparation method thereof

A neutral ink, rubbing technology, applied in the direction of ink, household appliances, applications, etc., can solve the problem of lack of rubbing performance and rubbing ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

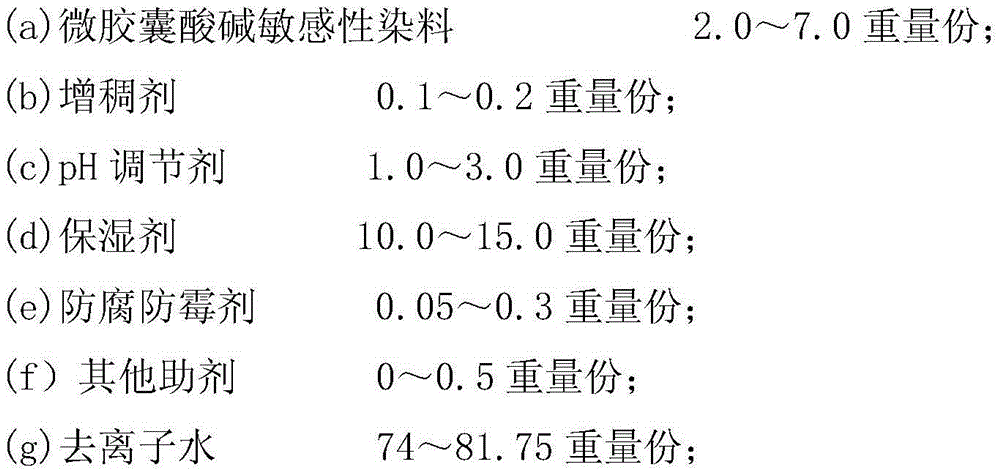

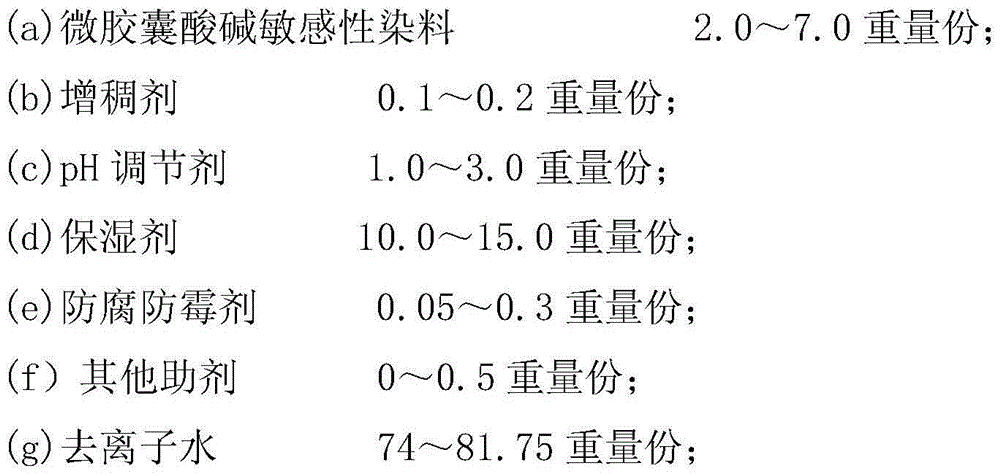

[0077] The invention provides a kind of preparation method of described erasable neutral ink, comprises the steps:

[0078] (a) The neutral ink component of component (A) is prepared according to the following steps:

[0079] Moisturizing agent, anti-mildew preservative, auxiliary agent, pH regulator, and microcapsule acid-base sensitive dye are added into the water in sequence.

[0080] After stirring well, add the thickener, stir well again, filter and defoam;

[0081] (b) A wipe liquid component providing component (B).

[0082] In a specific embodiment of the present invention, the thickener is preformed into a colloid, and then the method is used to prepare neutral ink.

[0083] Unless otherwise specified, various raw materials of the present invention can be obtained commercially; or prepared according to conventional methods in the art. Unless otherwise defined or stated, all professional and scientific terms used herein have the same meanings as those familiar to th...

preparation Embodiment 1

[0088] Table 1 can wipe neutral ink embodiment 1

[0089] type

components

dye

Microencapsulated Acid Blue 93

pH regulator

thickener

Modified bentonite

[0090] moisturizer

Antiseptic and antifungal agent

Rocima623 (Rohm and Haas)

water

Deionized water

Auxiliary

Tween-20

[0091] Add 81 grams of water, 10 grams of humectant, 0.5 grams of additives, 2 grams of pH regulators, 0.3 grams of anti-corrosion and anti-mold agents, and 3 grams of dyes into the reaction kettle with paddle stirring, and stir evenly; then stir at a low speed Slowly add the prefabricated colloid with a thickener content of 0.15 g, and after the addition, increase the speed and stir evenly. Finally, filter and defoam to get the finished product.

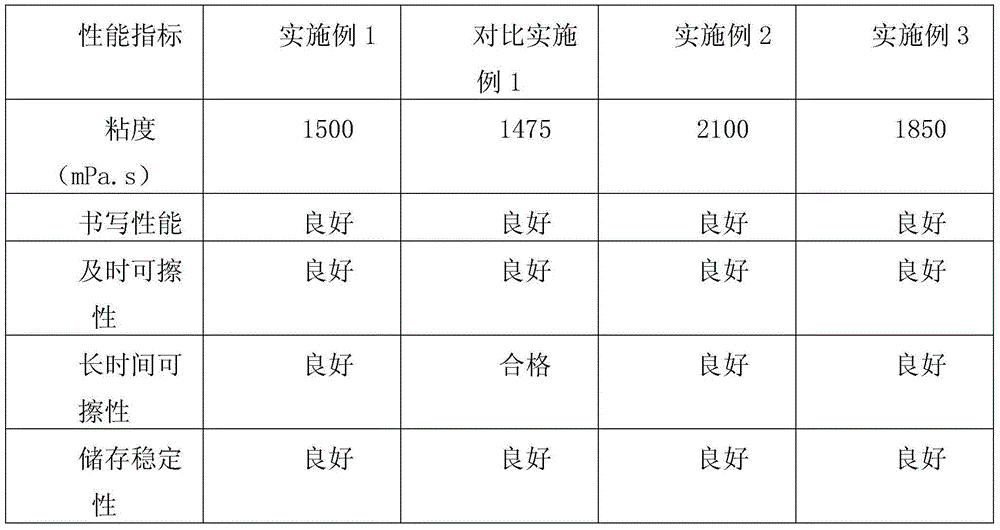

[0092] The obtained erasable neutral ink product has good writing performance, good timely erasability and long-term erasability.

preparation Embodiment 2

[0094] Table 2 can wipe neutral ink embodiment 2

[0095] type

components

dye

Microencapsulated Direct Yellow 4

pH regulator

thickener

Antiseptic and antifungal agent

Proxel XL2 (United Kingdom Colloids Limited)

water

Deionized water

Auxiliary

Tween 80

[0096] Add 80 grams of water, 10 grams of humectant, 0.5 grams of additives, 3 grams of PH regulators, 0.3 grams of anti-corrosion and anti-mold agents, and 3 grams of dyes into the reaction kettle with paddle stirring, and stir evenly; then stir at a low speed Slowly add the prefabricated colloid with a thickener content of 0.15 g, and after the addition, increase the speed and stir evenly. Finally, filter and defoam to get the finished product.

[0097] The obtained erasable neutral ink product has good writing performance, good timely erasability and long-term erasability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com