Printing ink composition with water-soluble solvent, application of printing ink composition, and printed circuit board

An ink composition, water-soluble technology, applied in the directions of printed circuit parts, inks, applications, etc., can solve the problems that the degree of improvement needs to be improved, and the problems such as ink overflow have not been solved, and achieve good solder heat resistance and good heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

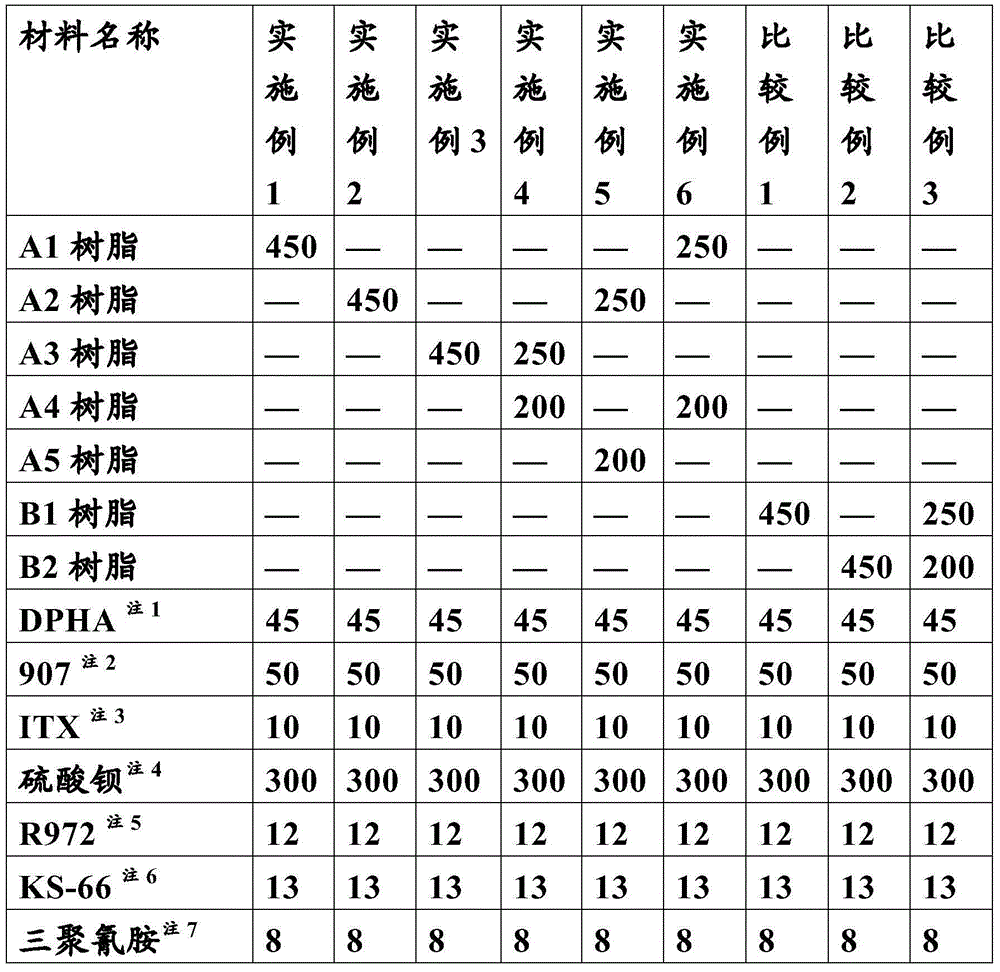

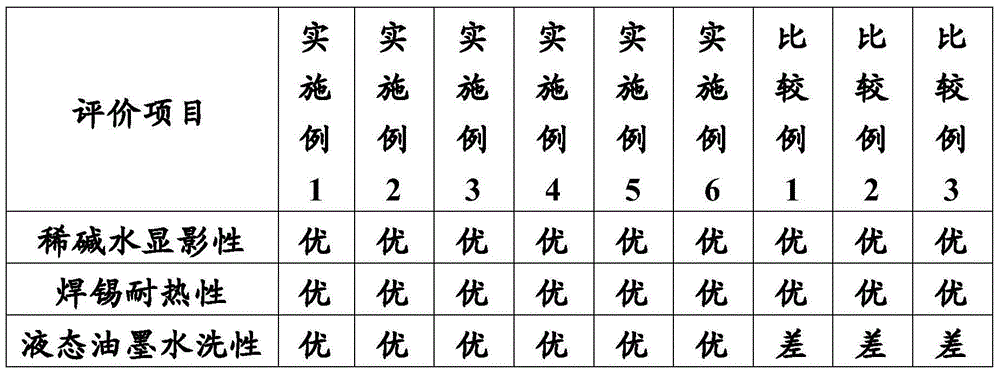

Examples

Synthetic example 1

[0085] Add 203 grams of o-cresol novolac epoxy resin (Shandong Shengquan 704M, epoxy equivalent 203), 0.5 grams of hydroquinone, and 250 grams of diethylene glycol ethyl ether acetate (water-soluble solvent) into a three-necked flask, stir, and heat Heat and dissolve at 100°C to 110°C for 1 hour. After ensuring complete dissolution, cool down to 90°C, add a solution of 72 grams of acrylic acid and 3 grams of N,N dimethylbenzylamine dropwise, and finish the drop within three hours. The temperature is controlled during the process 90-100°C, after the dropwise addition, raise the temperature to 105°C to 110°C for 12 hours, the measured acid value is less than 10mgKOH / g, the temperature of the material is lowered to 90°C, add 100 grams of tetrahydrophthalic anhydride, and keep at 90-95°C for 4 hour, detect with infrared spectrometer, 1780cm-1 peak disappears, stop reaction, temperature is lowered to room temperature, obtains tea brown resin solution, resin viscosity is 260dPa.s / 25 ...

Synthetic example 2

[0087]Add 210 grams of Kunshan Nanya o-cresol novolac epoxy resin NPCN-704 (epoxy equivalent 210, softening point 70-80°C) and 250 grams of dipropylene glycol methyl ether ether acetate (water-soluble solvent) into a three-necked flask, stir and heat Heat and dissolve at 100°C to 110°C for 1 hour. After ensuring complete dissolution, cool down to 90°C, add 72 grams of acrylic acid, 0.3 grams of hydroquinone, and 1.8 grams of triphenylphosphine, heat to 100-120°C, and react for 15 hours , the acid value is less than 5mgKOH / g, add 100 grams of tetrahydrophthalic anhydride, control the temperature at 90 to 100 ° C for 4 hours, detect with an infrared spectrometer, the 1780cm-1 peak disappears, stop the reaction, and obtain a light yellow resin solution with a viscosity of 300dPa. s / 25 ℃, solid content 60%, the resin of acid value 60mgKOH / g, number average molecular weight is 2336, and resin code is A2 (wherein the mass percent that contains water-soluble organic solvent is 40%, ba...

Synthetic example 3

[0089] Add 210 grams of Kunshan Nanya o-cresol novolac epoxy resin NPCN-704 (epoxy equivalent 210, softening point 70-80°C) and 250 grams of 1,4-butyrolactone (water-soluble solvent) into a three-necked flask, stir and heat Heat and dissolve at 100°C to 110°C for 1 hour. After ensuring complete dissolution, cool down to 90°C, add 72 grams of acrylic acid, 0.3 grams of hydroquinone, and 1.8 grams of triphenylphosphine, heat to 100-120°C, and react for 15 hours , the acid value is less than 5mgKOH / g, add 100 grams of tetrahydrophthalic anhydride, control the temperature at 90 to 100 ° C for 4 hours, detect with an infrared spectrometer, the 1780cm-1 peak disappears, stop the reaction, and obtain a light yellow resin solution with a viscosity of 300dPa. s / 25 ℃, solid content 60%, the resin of acid value 60mgKOH / g, number average molecular weight is 1987, and resin code is A3 (wherein the mass percent that contains water-soluble organic solvent is 40%, based on the gross weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com