Aeration pipe, aeration disc and immersion etching machine

A technology for aeration tubes and aeration discs, applied in the field of aeration discs, immersion etching machines, and aeration tubes, can solve problems such as weak air flow at the edge of aeration discs and affect the surface quality of glass substrates, and achieve a strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

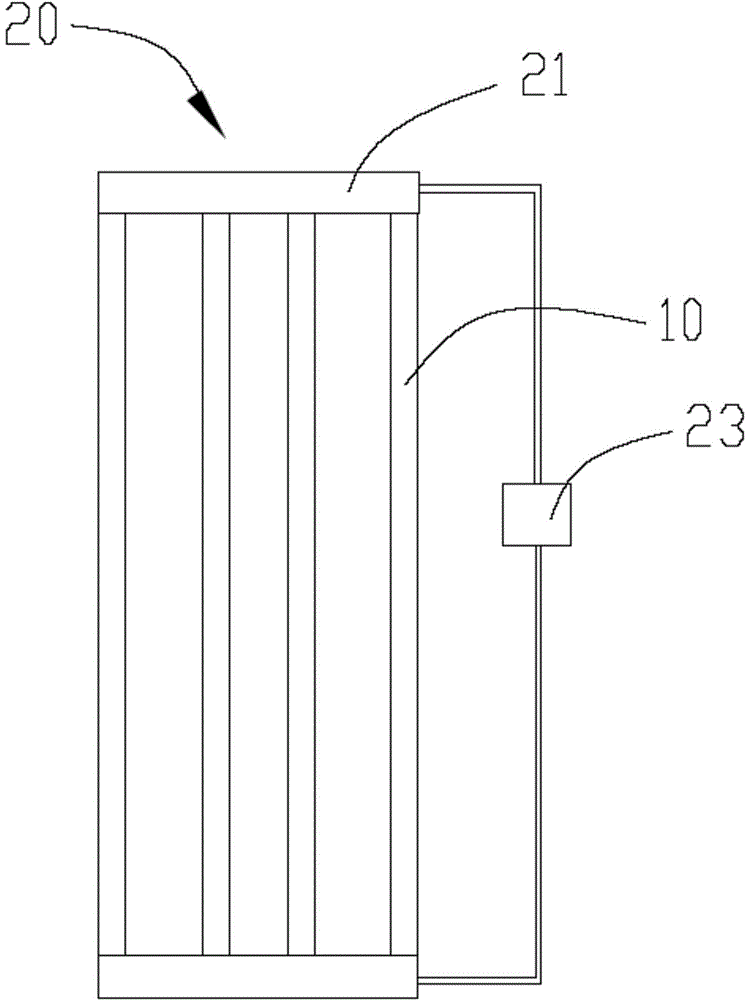

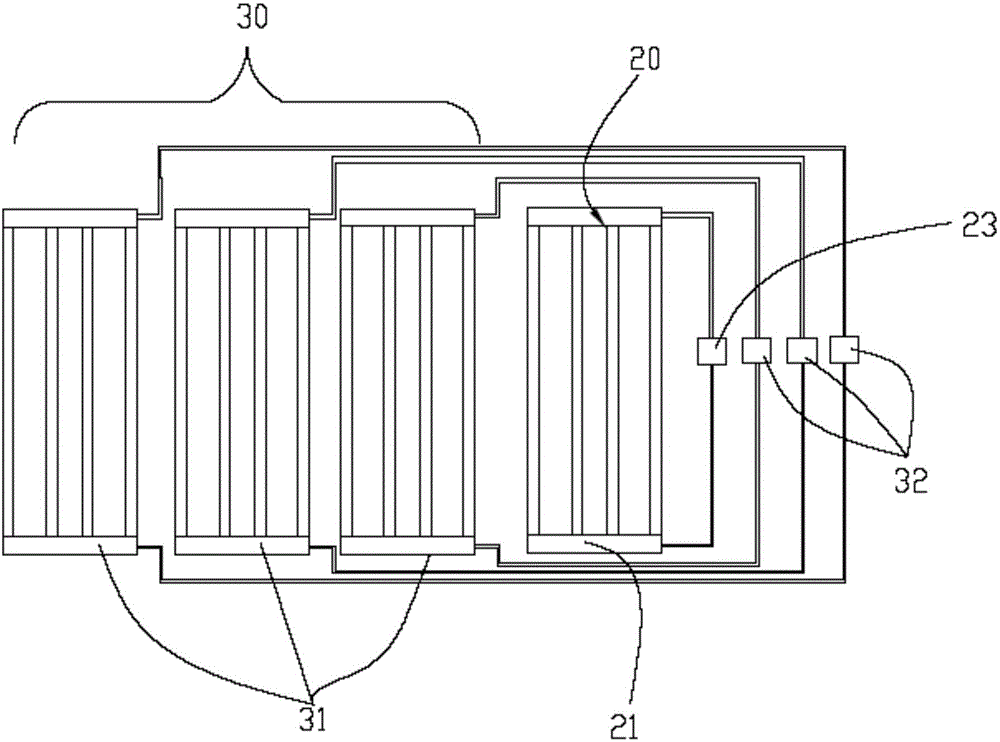

[0022] A preferred embodiment of the present invention provides an aeration tube and an aeration pan. The aeration pan is used to provide air pressure for the etching liquid when the immersion spray etching machine etches the glass substrate of the liquid crystal display.

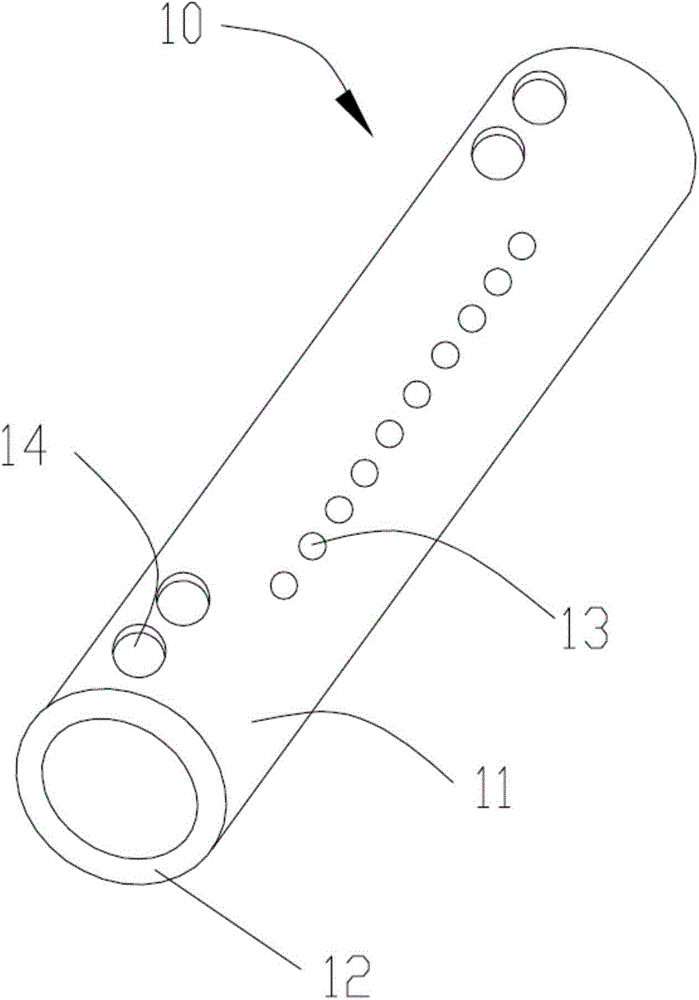

[0023] see figure 1 , the aeration tube 10 of the present invention is a hollow tube body, which includes a tube wall 11 , a cavity (not marked) surrounded by the tube wall 11 and open ends 12 located at both ends of the tube wall 11 . The pipe wall 11 is provided with several first air holes 13 arranged in a line along the axial direction. The plurality of linearly arranged first air holes 13 are at least arranged in one row. At least one second vent hole 14 is provided on the tube wall 11 near each ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com