A modular cabinet unit and combined cabinet

A modular and cabinet technology, applied in the direction of rack/frame structure, etc., can solve the problems of heavy design workload, low internal and external pressure bearing of the cabinet, high price, etc., to reduce workload, improve electronic equipment, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

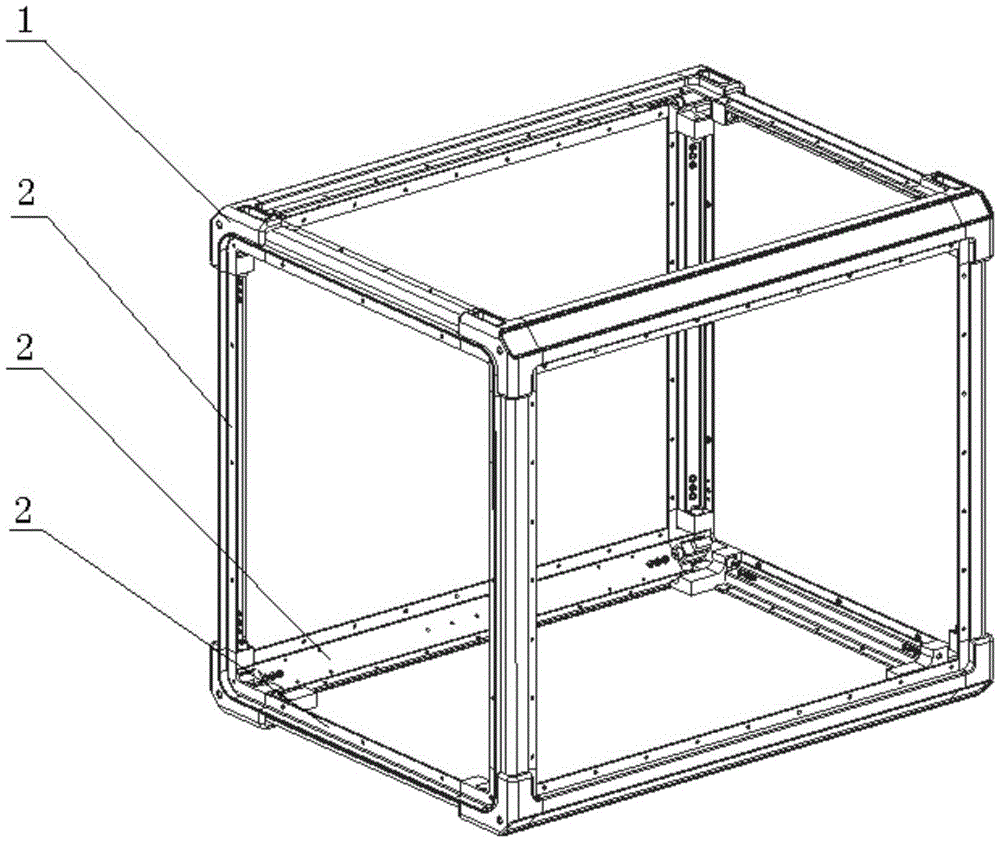

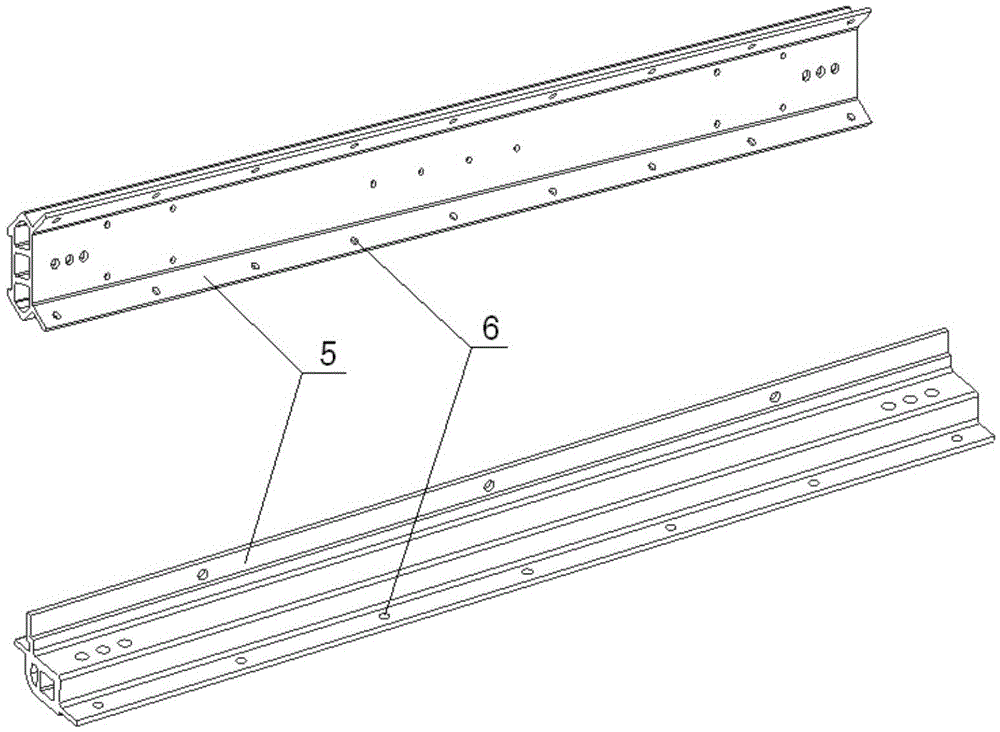

[0022] In the present invention, the corner block 1 and the beam 2 are spliced into a cabinet frame as the main body of the cabinet to perform functions such as force bearing, positioning and installation. A complete cabinet unit consists of eight corner blocks 1 and twelve beams 2 . The corner block 1 and the beam 2 are connected by threads, welding, pins or combinations. The frame as a whole has high strength and rigidity. The effect of external forces on the cabinet. The cabinet cladding plate 8 can be freely assembled on the six sides of the frame according to specific application requirements.

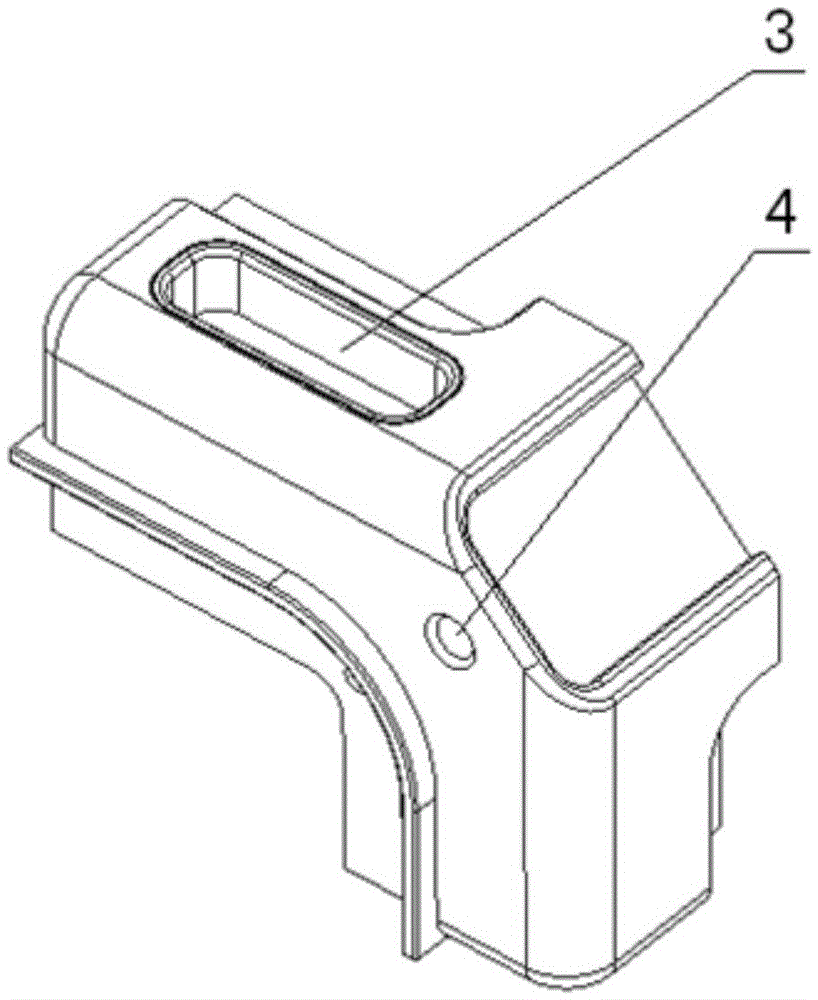

[0023] The size and shape of the corner block 1 are fixed, and a positioning groove 3 and a locking interface 4 are provided on the flat surface of the corner block 1 . When the cabinets are stacked in double or multiple layers, positioning pins can be installed on the positioning groove 3 of the corner block 1 to realize the precise stacking between the upper and lower layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com