Large-ring-gear externally-expanded type efficient gear shaping clamp

A high-efficiency, gear-shaping technology, which is applied in the direction of gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of poor clamping stability of manual clamps, unsuitable mass production, and poor processing accuracy of parts, etc., to achieve clamping The process is stable and reliable, the clamping force is constant, and the effect of preventing iron filings from accumulating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

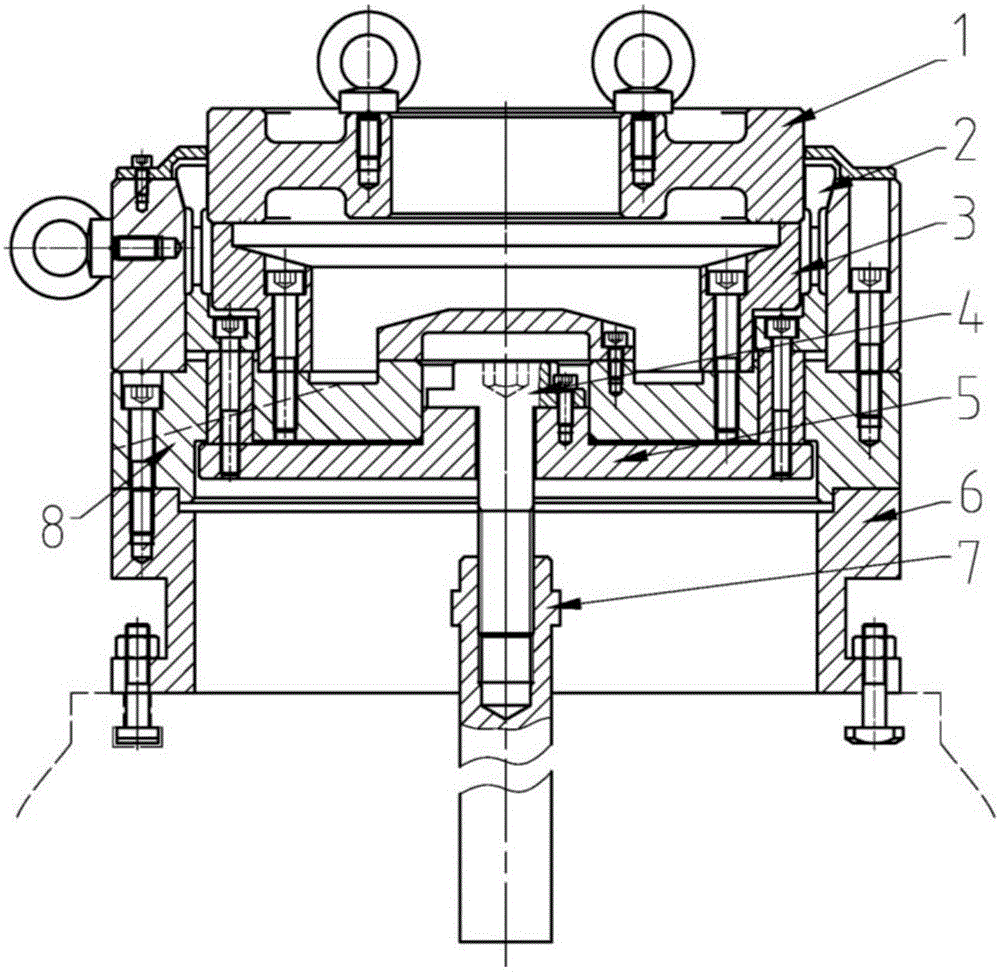

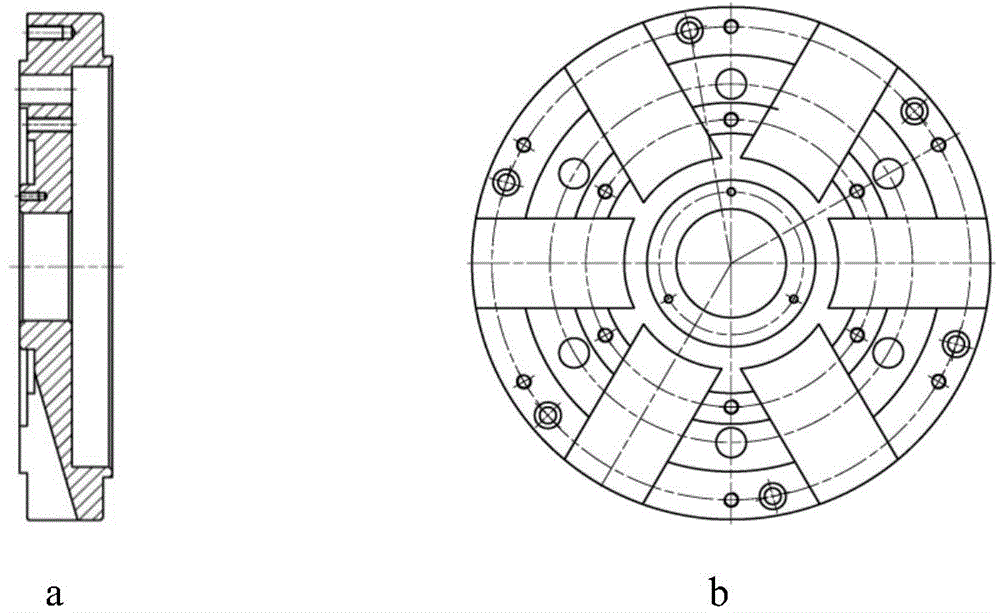

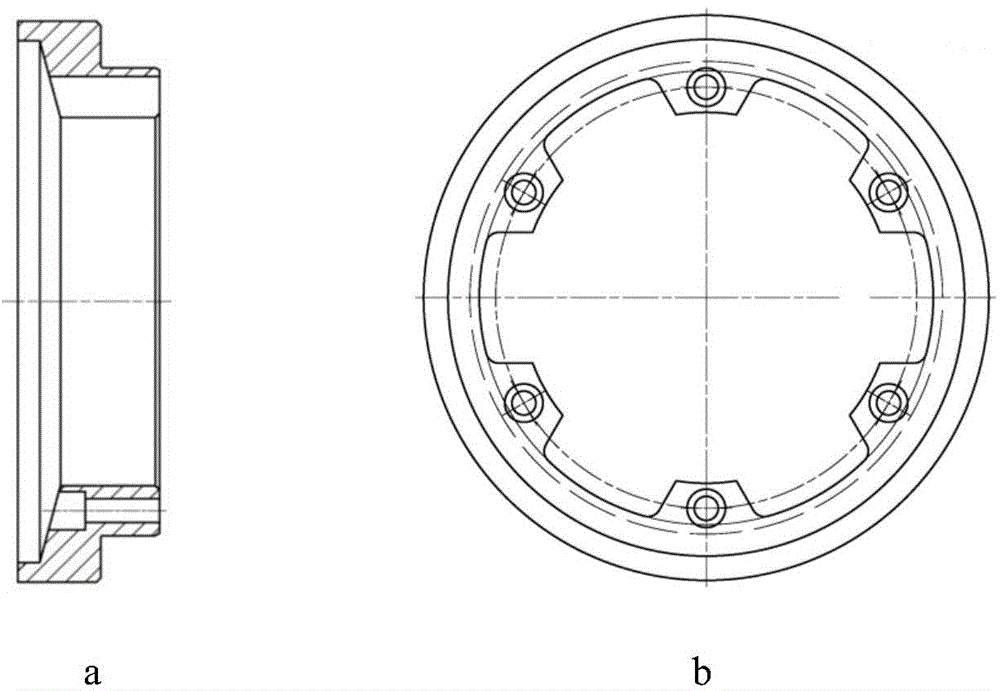

[0023] see Figure 1 to Figure 6 , the present invention includes a base 6, and a body 8 installed on the base 6, the inner side of the body 8 is sequentially installed with a connection plate 5, an expansion sleeve 2 and a support 3; the base 6 is fixedly connected with the machine tool workbench. The middle part of the connection disc 5 is equipped with a pull rod 4, and the pull rod 4 passes through the connection disc 5 downwards and is screwed into the connection rod 7 installed on the sliding piston of the machine tool. The pull rod 4 is fixed on the connection plate 5 by screws. The support 3 is a petal-shaped tooth structure, and is matched with the upper chute of the body 8 to prevent the accumulation of iron filings from affecting the processing.

[0024] When in use, fasten the connecting rod 7 to the sliding piston of the machine tool first, then connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com