Numerically-controlled drilling and chamfering machine

A technology of chamfering machine and CNC slide table, which is applied in boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc. Problems such as low operation efficiency, to achieve the effect of saving manpower handling, preventing oil cylinder wall strain, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

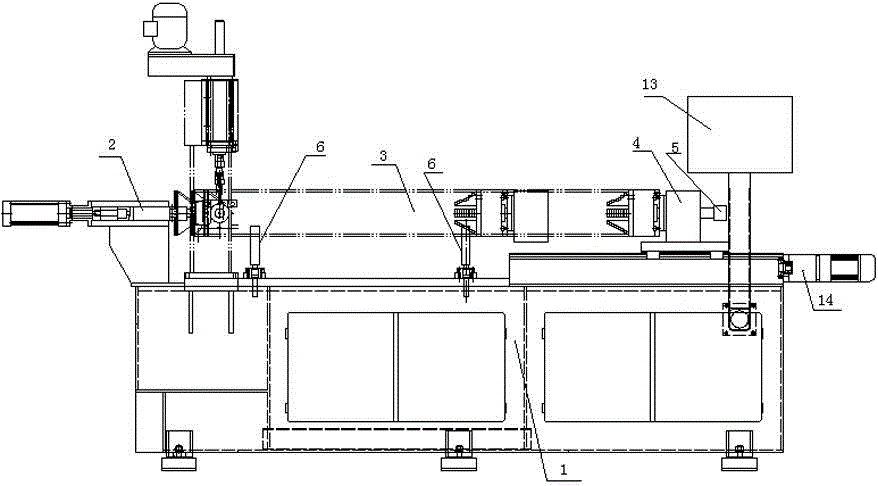

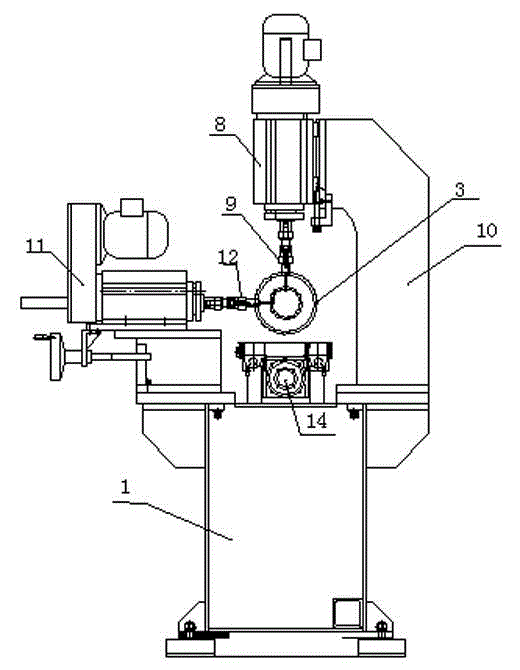

[0019] The present invention as figure 1 , 2 shown.

[0020] The CNC drilling and chamfering machine includes a working platform 1, an electric control system 13 is provided on the side of the working platform 1, a bracket 6 is provided in the middle of the working platform 1, a positioning and tightening device 2 is provided at one end of the working platform 12, and a positioning and tightening device 2 is provided at the other end. Servomotor 5 is provided with indexing plate 7, and indexing plate 7 is provided with tightening device two correspondingly; The working platform 1 outside positioning tightening device one 2 is provided with two drill floors through support arm 10, namely drill floor one 11 And drill floor two 8, two drill floors are provided with drill jacket two 9 and drill floor one 11 respectively.

[0021] Below the servo motor 5 and the index plate 7, a numerical control slide table 14 is arranged.

[0022] The positioning tightening device-2 is a pneum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com