Progressive die for manufacturing automobile seat hinge and method of progressive die

A car seat and hinge technology, which is applied in the field of continuous molds, can solve the problems of unsuitable lower hinges on the inner side of car seats, etc., and achieve the effects of overall structural design and arrangement, convenient and reliable use, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0061] The hinge finished product of the present invention is illustrated by taking the lower hinge inside the car seat as an example.

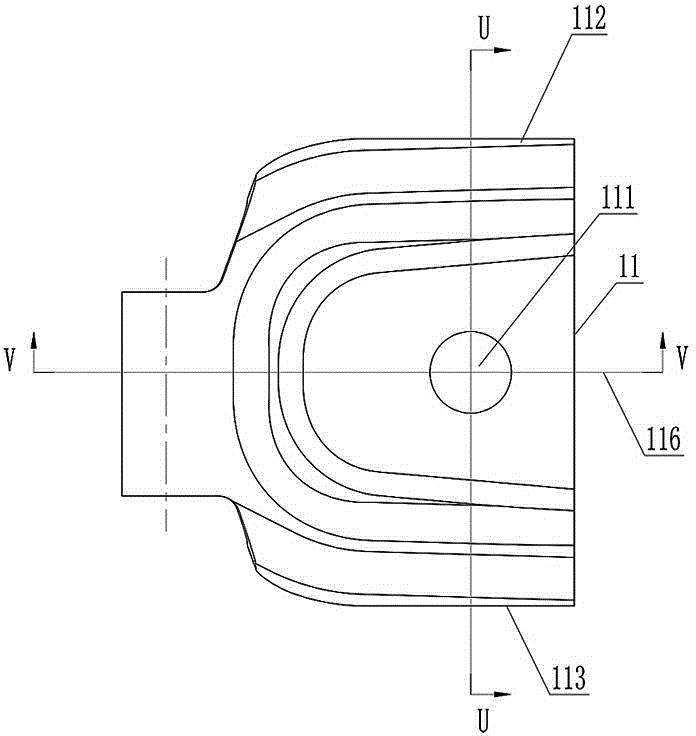

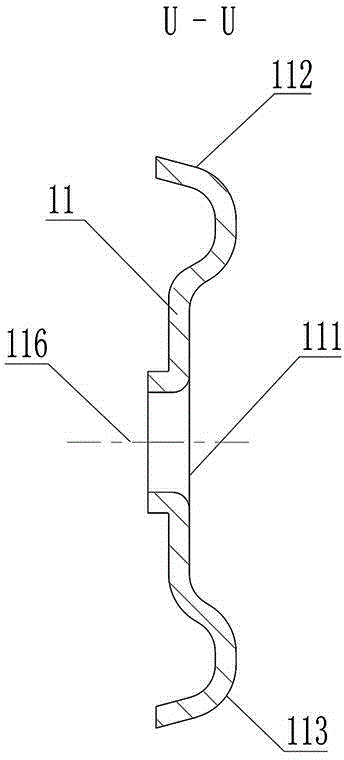

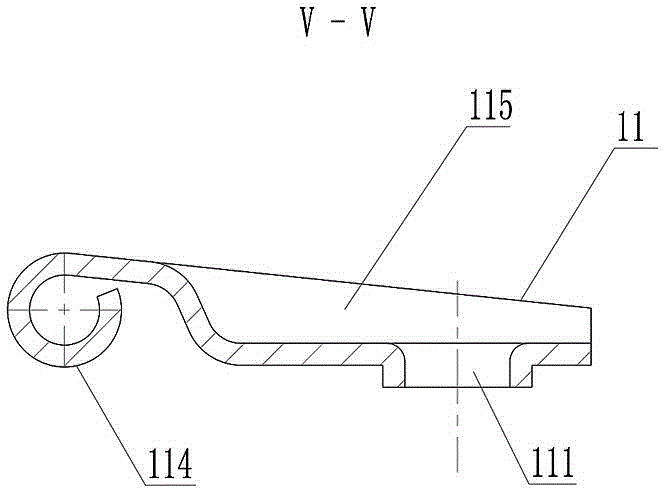

[0062] see Figure 1 ~ Figure 3 , which is the structure and shape of hinge one 11 in the finished hinge of the present invention, which hinge one 11 includes hinge one turning hole 111, hinge one first folding edge 112, hinge one second folding edge 113, hinge one roll Ring 114 and hinge-indented 115; hinge-turning hole 111 is opened on hinge-indented 115, and hinge-first folded edge 112 and hinge-second folded edge 113 are symmetrically distributed on hinge-turned-out hole 111 center line 116 sides.

[0063] see Figure 1 to Figure 6 , which is the structure and shape of the second hinge 12 in the finished hinge of the present invention. This hinge two 12 comprises hinge two turning holes 121, hinge two first fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com