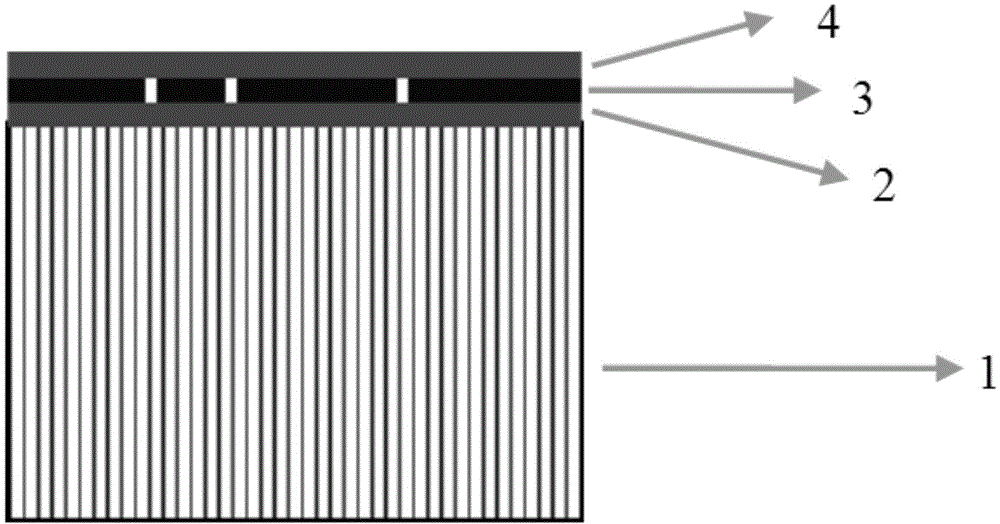

Multilayer gas separation composite membrane and preparation method thereof

A technology of gas separation and composite membrane, which is applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc. It can solve the problems of pore seepage and hard-to-separate cortex, so as to improve permeation flux, have good industrialization prospects, and suppress pore The effect of seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

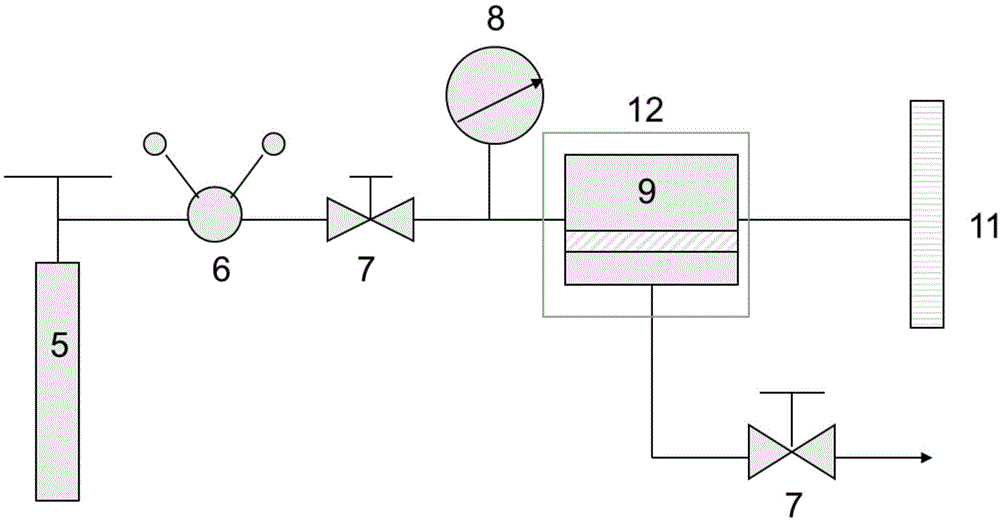

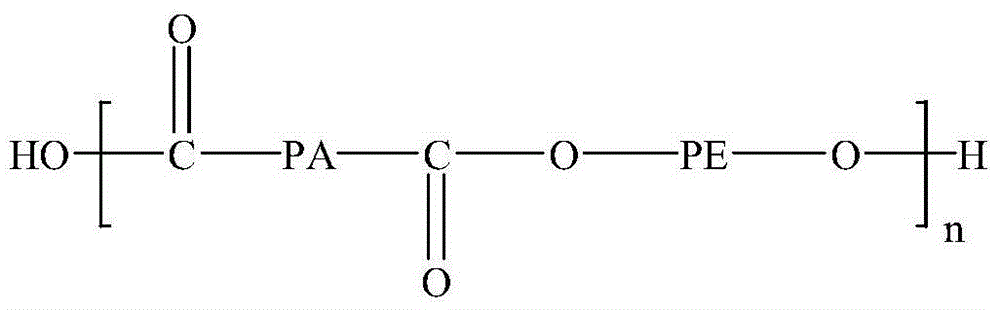

Embodiment 1

[0047] Prepare Pebax1074 (Pebax1074, model: 1074, French Arkema Company) n-butanol solution, heated and stirred to obtain a uniform transparent solution. After standing for defoaming, the coating liquid was coated on the surface of the polysulfone porous membrane by combining dip coating and wet coating, and the PSF / Pebax1074 composite membrane was obtained after desolventization. The separation performance of the membrane was tested, and the experimental results are listed in Table 1.

[0048] The experimental result of table 1 embodiment 1

[0049]

Embodiment 2

[0051] Prepare Pebax1074 n-butanol solutions with 1% and 3% mass concentrations respectively, and heat and stir to obtain a homogeneous transparent solution. After standing for defoaming, dip coating was used to coat the PDMS surface of composite membrane PSF / PDMS with coating liquid, and PSF / PDMS / Pebax1074 composite membrane was obtained after solvent removal. The separation performance of the membrane was tested, and the experimental results are listed in Table 2.

[0052] The experimental result of table 2 embodiment 2

[0053]

Embodiment 3

[0055] Prepare a Pebax1074 n-butanol solution with a mass concentration of 1%, heat and stir evenly, add different masses of GTA, and continue heating and stirring to obtain Pebax1074-GTA coating solutions with different mass ratio concentrations. After static defoaming, the PDMS surface of the PSF / PDMS composite membrane was coated by dip coating method, and the PSF / PDMS / Pebax1074-GTA multilayer composite membrane was obtained after the solvent was removed. The separation performance of the membrane was tested, and the experimental results are listed in Table 3.

[0056] The experimental result of table 3 embodiment 3

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com