High flow and overpressure resistant hyperfiltration membrane with laminar hole structure and method of preparing the same

An ultrafiltration membrane and high-flux technology, applied in the field of membrane separation, can solve the problems of membrane pollution resistance, temperature resistance, solvent resistance, pore size uniformity, mechanical stability, permeation flux and pressure resistance, etc. high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Polysulfone-Fe with layered pore structure 3 o 4 Preparation method of flat ultrafiltration membrane

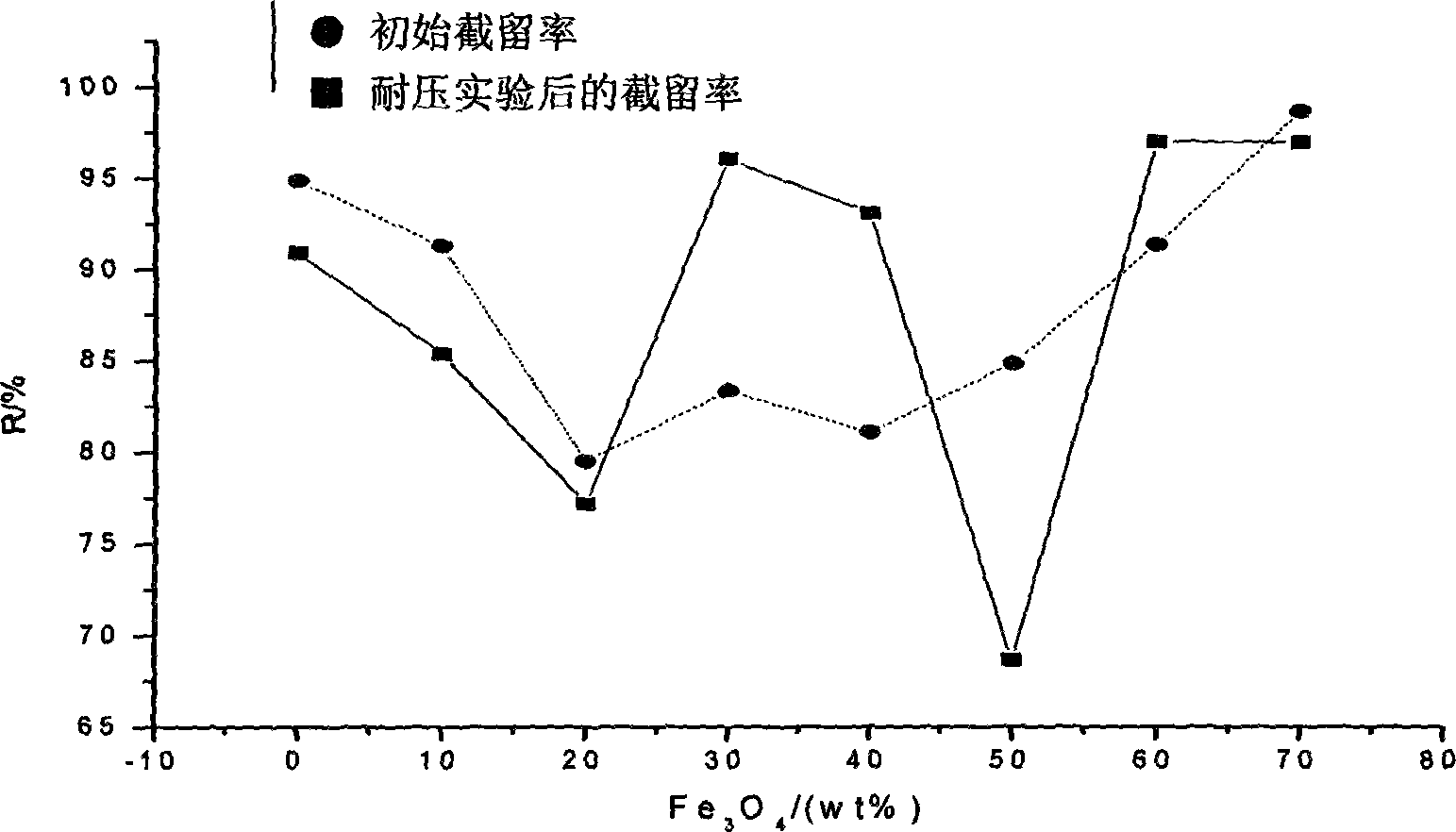

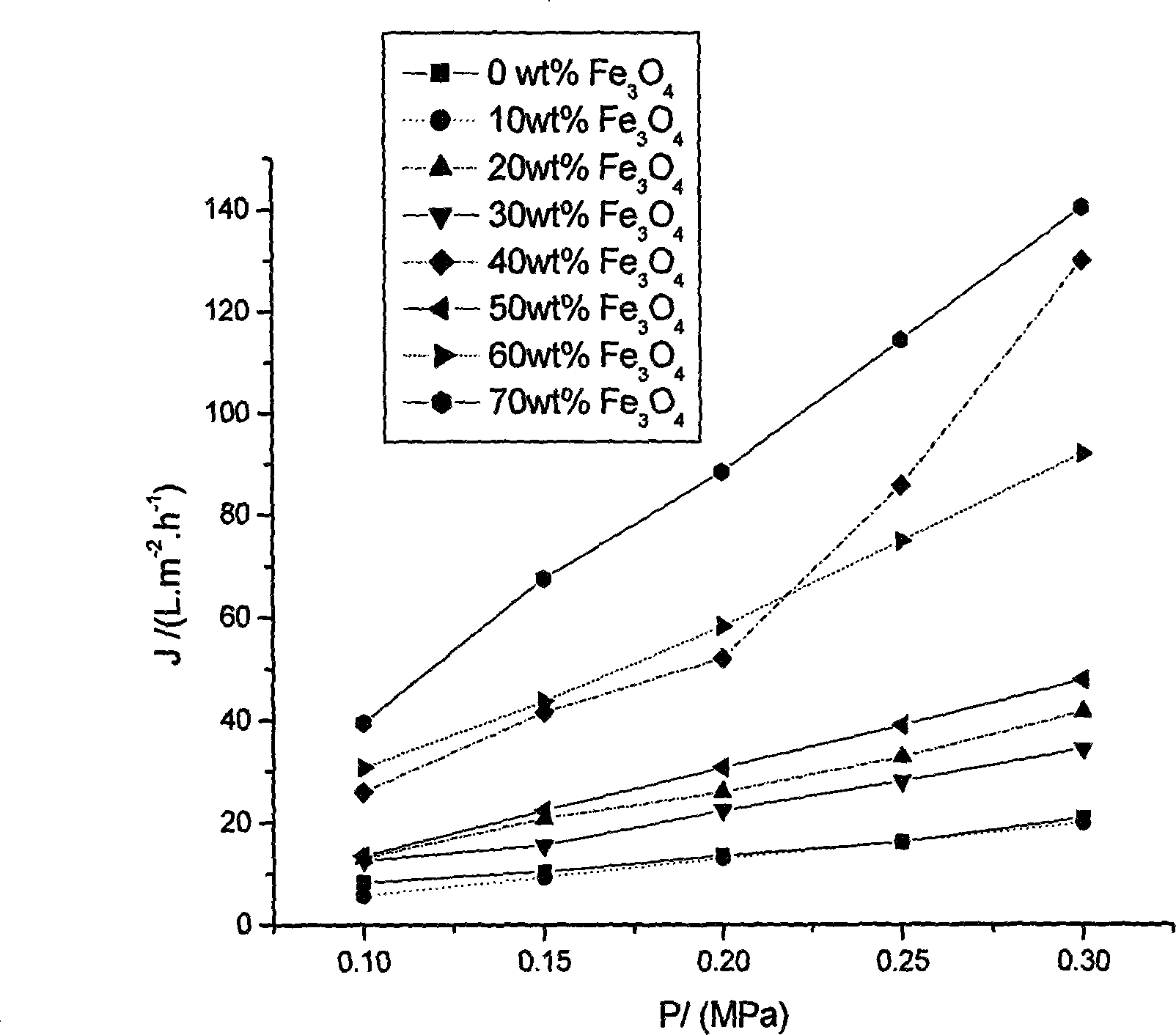

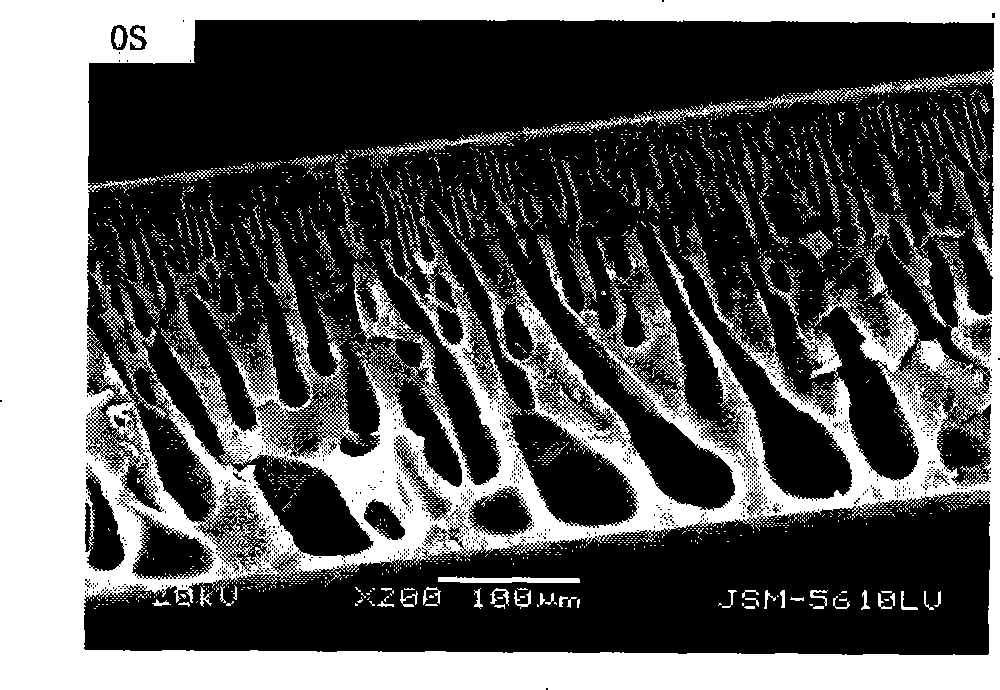

[0037] Take 100g of N,N-dimethylacetamide (DMAC) and put them in 8 iodine measuring bottles, respectively add 5.0g of polyvinylpyrrolidone (PVP) to them, and wait for it to fully dissolve; weigh 0.0g, 3.1g , 7.0g, 12.0g, 18.7g, 28.0g, 42.0g and 65.3g ferric oxide (Fe 3 o 4 ), and mixed evenly with 28.0g polysulfone (PSf) respectively, added to the above-mentioned 8 iodine measuring bottles, shaked quickly, shaked and dissolved evenly at 55-60°C, and defoamed. Scrape the film on the glass plate, evaporate in the air (humidity less than 50%, temperature 20°C) for about 5 seconds, put it in a horizontal magnetic field (magnetic field strength 1000-1500 Gauss) and continue to evaporate for 25 seconds, put it in water under the action of the magnetic field After gelling for 15 minutes, take out the membrane and soak it in distilled water for 24 hours to obtai...

Embodiment 2

[0043] Get 80ml dimethylacetamide (DMAC) and 20ml N-methylpyrrolidone and place in the iodine measuring bottle, add 13.0g polyethylene glycol respectively thereinto, and wait for it to fully dissolve; Weigh 70.0g magnetic carbon nanotubes, 5.0 Mix 5.0 g of polysulfone and 5.0 g of polyethersulfone into the above-mentioned iodine measuring bottle, shake quickly, dissolve evenly with ultrasonic vibration at 55-60°C, and then defoam. Scratch the film on the non-woven fabric, evaporate in the air (humidity less than 60%, temperature 22°C) for 3 seconds, put it in a horizontal magnetic field (magnetic field strength 3000-4500 Gauss) and continue to evaporate for 12 seconds, and put it in water under the action of the magnetic field After gelling for 15 minutes, the membrane was taken out and soaked in distilled water for 24 hours to obtain a magnetized membrane, and its pure water permeation flux was measured to be 813L.m -2 .h -1 (25°C, 0.4MPa), the rejection rate to bovine serum...

Embodiment 3

[0045] Take 150ml of dimethylacetamide (DMAC) and place it in an iodine measuring bottle, add 10.0g of polyethylene glycol and 3.0g of polyvinylpyrrolidone to it, and wait for it to fully dissolve; weigh 30.0g of Fe 3 o 4 , 10.0 g of magnetic carbon nanotubes, and 5.0 g of polysulfone were mixed and added to the above-mentioned iodine flask, shaken up quickly, dissolved evenly by ultrasonic vibration at 55-60° C., and defoamed. Coating film on polyester non-woven fabric, immediately put it in a horizontal magnetic field (magnetic field strength 6300-7200 gauss), evaporate in air (humidity less than 60%, temperature 25 ℃) environment for 30s, and then put distilled water under the action of magnetic field After gelling for 25 minutes, the membrane was taken out and soaked in distilled water for 24 hours. The pure water permeation flux of the membrane was measured to be 1190L.m -2 .h -1 (25°C, 0.3MPa), the rejection rate of bovine serum albumin is 97.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com