Permanent magnet cavity structure robust design method capable of reducing iron loss of built-in permanent magnet motor

A permanent magnet motor and permanent magnet technology, which is applied to the shape/style/structure of the magnetic circuit, the rotating parts of the magnetic circuit, and the manufacture of the stator/rotor body. , to achieve the effect of reducing harmonic components, electromagnetic torque fluctuation and cogging torque, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

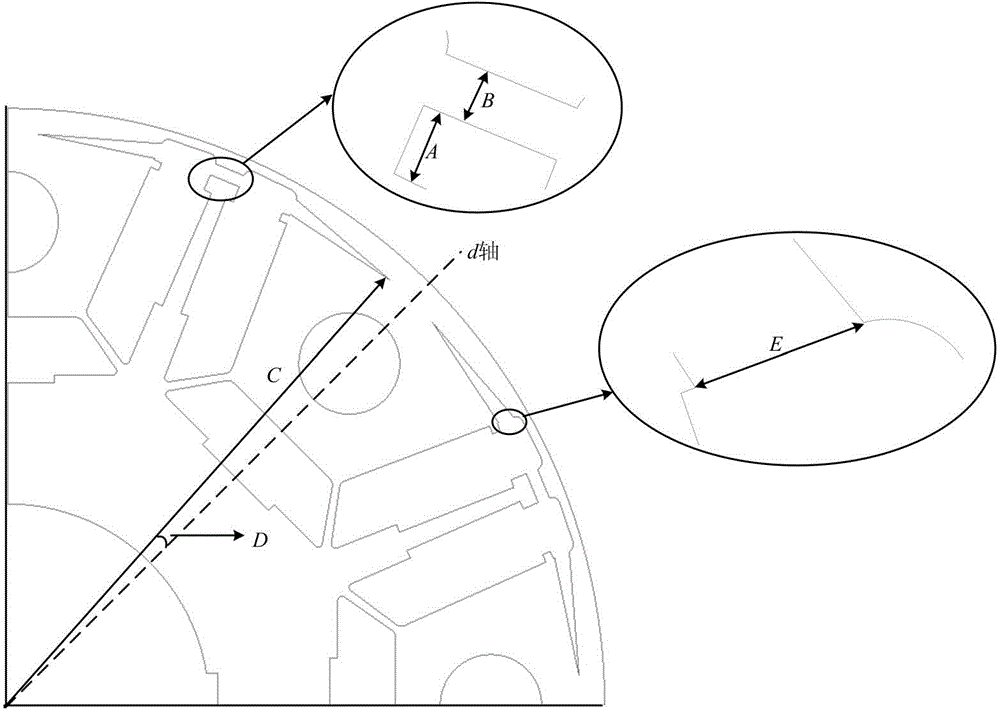

[0025] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Taking a built-in permanent magnet motor as an example, the robustness design of the permanent magnet cavity structure to reduce the iron loss of the built-in permanent magnet motor is carried out. The parameters of the motor are shown in Table 1.

[0026] Table 1 Inner rotor motor parameters

[0027] parameters

the symbol

value

unit

Rated speed

n N

1800

r / min

Rated torque

T N

960

N m

Number of pole pairs

P

4

--

Number of slots

Q

48

--

Rotor air gap radius

R ra

148.2

mm

air gap length

δ

1.8

mm

R sy

232.5

mm

core length

l

210

mm

permanent magnet residual flux density

B r

1.19

T

[0028] Permanent magnet relative perme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com