Coupling capacitor

A coupling capacitor and electrode technology, which is applied in the field of coupling capacitors, can solve problems such as unsatisfactory use requirements, high high-frequency loss, and poor stability, and achieve the effects of stable and reliable practicability, low high-frequency loss, and strong overcurrent capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

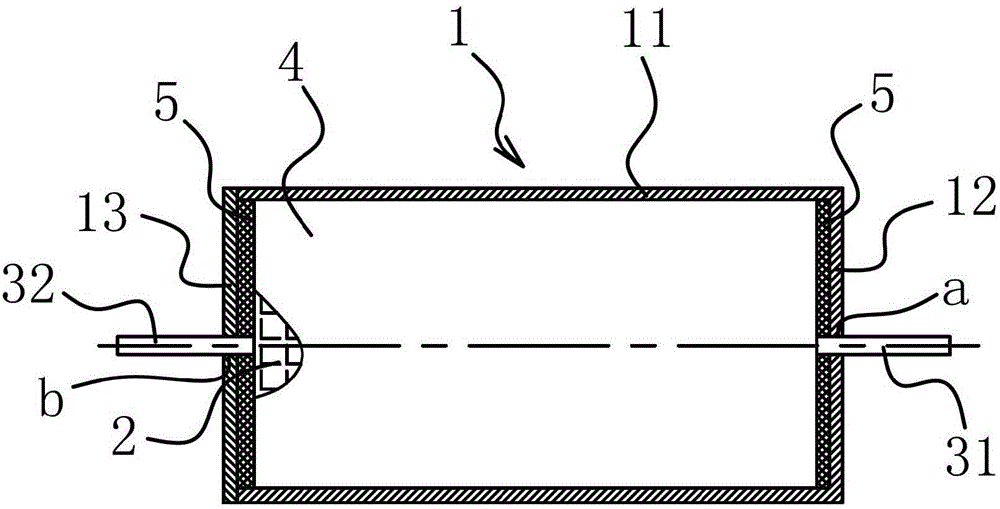

[0013] like figure 1 As shown, the coupling capacitor includes a cylindrical metal case 1, the metal case 1 is any one of oval and circular, and a winding core 2 is arranged inside the metal case 1, and the winding core 2 One end is provided with the first electrode 31 whose end extends to the outside of the winding core 2, and the other end is provided with the second electrode 32 whose end extends to the outside of the winding core 2, and the winding core 2 is provided with The Mylar tape layer 4 wrapped outside the winding core 2, the metal casing 1 is provided with a potting layer 5 between one end and the winding core 2, and between the other end and the winding core 2, The metal casing 1 includes a cylindrical body 11 with one end open, and the other end has a shell bottom 12. The cylindrical body 11 and the shell bottom 12 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com