Acetone gas sensor and preparation method thereof

A gas sensor, acetone technology, applied in the direction of material resistance, etc., to achieve the effect of simple preparation process, simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The beneficial effects of the present invention will be described in detail below in conjunction with the embodiments of the accompanying drawings, aiming at helping readers better understand the essence of the present invention, but not limiting the implementation and protection scope of the present invention.

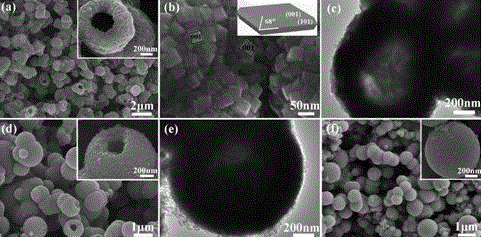

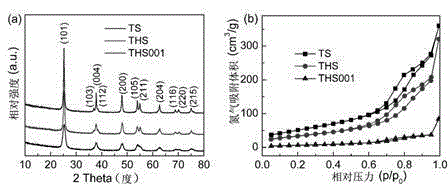

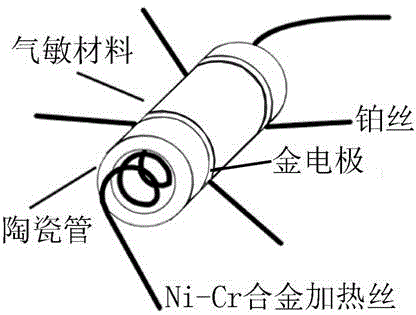

[0016] Three-dimensional hierarchical TiO with exposed high-energy {001} crystal planes was first prepared by a hydrothermal method 2 Hollow sphere material, then alumina ceramic tube coated with fork-shaped gold electrodes on the outer surface as the carrier, Ni-Cr alloy heating wire as the heating element, platinum wire to lead the electrode, and the conventional process of side-heated gas sensor device for gas sensing The material is coated, welded and aged to make a semiconductor gas sensor device, and finally the gas sensor performance test is carried out on the obtained device.

[0017] The hydrothermal method to prepare TiO with high-energy {001} facet e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com