Modular continuous microwave freeze-drying chamber and microwave freeze-drying equipment containing said freeze-drying chamber

A technology of microwave freeze-drying and freeze-drying chamber, which is applied in the direction of lighting and heating equipment, drying, drying machine, etc. It can solve the problems of uneven distribution of microwave field, inability to provide sufficient shear stress, and affect freeze-drying effect. Achieve the effect of ensuring the uniformity of microwave loading, satisfying the increase of output and expanding production, and solving the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

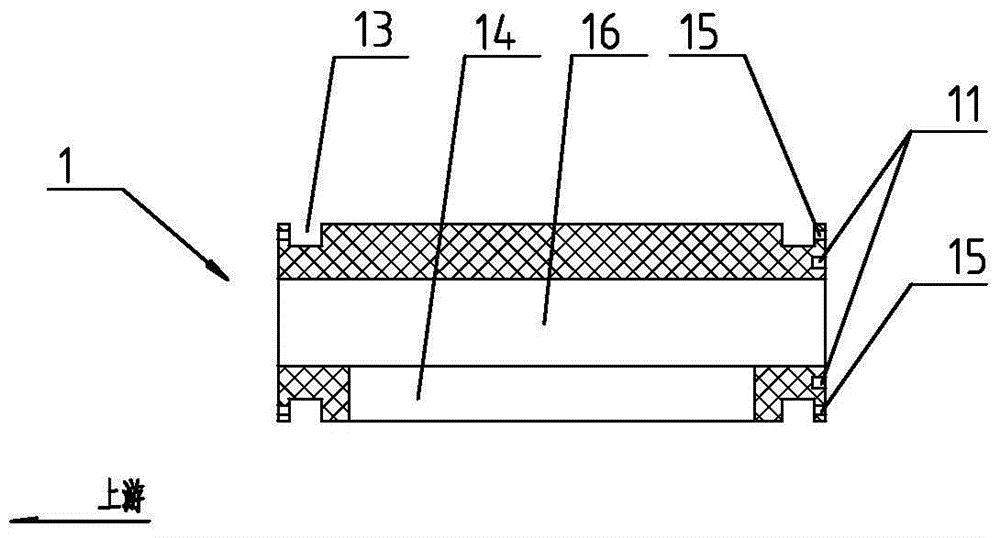

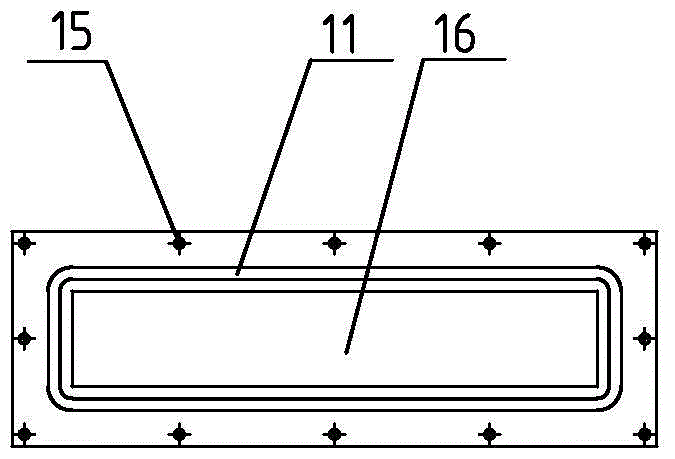

[0060] The chamber body 1 is made of high-density polyethylene (HDPE) through an injection molding process, and the microwave shielding plate 2 is made of a 3A21 aluminum alloy through a cutting process. During the freeze-drying process, affected by the heat transfer of the freeze-dried raw materials, the temperature of the chamber body 1 and the microwave shielding plate 2 drops to 10°C, and the initial temperature is calculated as normal temperature of 25°C, with a temperature difference of 15°C.

[0061] In addition, the coefficient of linear expansion of the material is:

[0062] HDPE: 180×10 -6 / ℃

[0063] 3A21: 23.2×10 -6 / ℃

[0064] According to the single-direction length of a single modular microwave vacuum chamber of 1200mm, at a temperature difference of 15°C, the size of the gap caused by the inconsistent linear expansion coefficients of the two materials is:

[0065] (1200mm×15℃×180×10 -6 / ℃-1200mm×15℃×23.2×10 -6 / ℃) / 2=1.4mm

[0066] A solid elastic sealing...

Embodiment 2

[0073] The main compartment 1 is made of HDPE, and the microwave shielding plate 2 is made of SUS304 stainless steel. During the freeze-drying process, the temperature of the chamber body 1 and the microwave shielding plate 2 drops to 5°C, the initial temperature is calculated as normal temperature of 25°C, and the temperature difference is 20°C.

[0074] The linear expansion coefficient of HDPE is: 180×10 -6 / ℃

[0075] The linear expansion coefficient of SUS304 is: 17.2×10 -6 / ℃

[0076] Calculated according to the longest single-direction length of 1500mm of a single modular microwave vacuum cavity, at a temperature difference of 20°C, the size of the gap caused by the inconsistent linear expansion coefficients of the two materials is:

[0077] (1500mm×20℃×180×10 -6 / ℃-1500mm×20℃×17.2×10 -6 / ℃) / 2=2.44mm

[0078] A solid elastic sealing ring made of rubber, a silicone sealing ring with an internal pressure of 0.1mPA filled with nitrogen, a silicone sealing ring with an...

Embodiment 3

[0082] The same materials and operating parameters as in Example 2 were used, the difference being that the effectiveness of a longer modular microwave vacuum cavity was tested, and the length of a single cavity was 3000 mm. The calculated gap size is:

[0083] (3000mm×20℃×180×10 -6 / ℃-3000mm×20℃×17.2×10 -6 / ℃) / 2=4.88mm

[0084] Obviously, due to the increase in the length of a single cavity, the gap caused by the difference in linear expansion coefficient also increases significantly, which intensifies the difficulty of cavity sealing.

[0085]The influence of the silicone seal ring filled with He gas with an internal pressure of 0.5mPA and the silicone seal ring filled with He gas with an internal pressure of 1.2mPA on the vacuum degree and air leakage rate in the chamber were tested respectively, and the results are as follows:

[0086]

[0087] It can be seen that the air-filled sealing ring can meet the airtightness requirements of the freeze-drying chamber with a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com