A kind of porcelain brick and its production method and production line

A production method and technology of porcelain tiles, applied in the field of porcelain tiles, can solve the problems of thin decorative patterns on the surface of porcelain tiles and easy wear and tear, and achieve rich color textures, good wear resistance, durability and layering strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

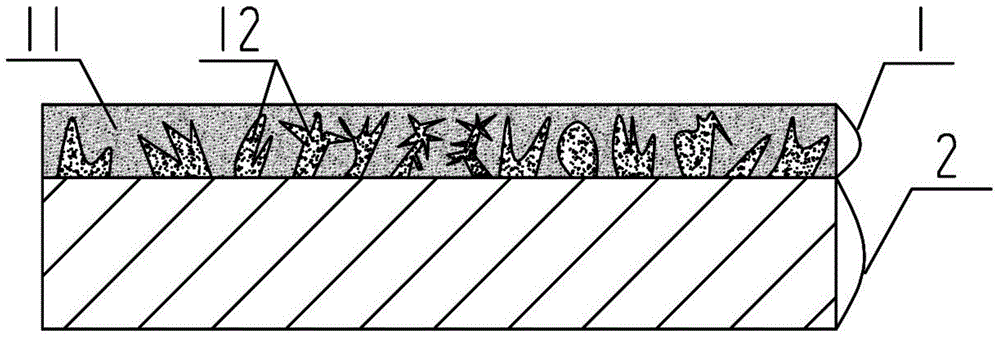

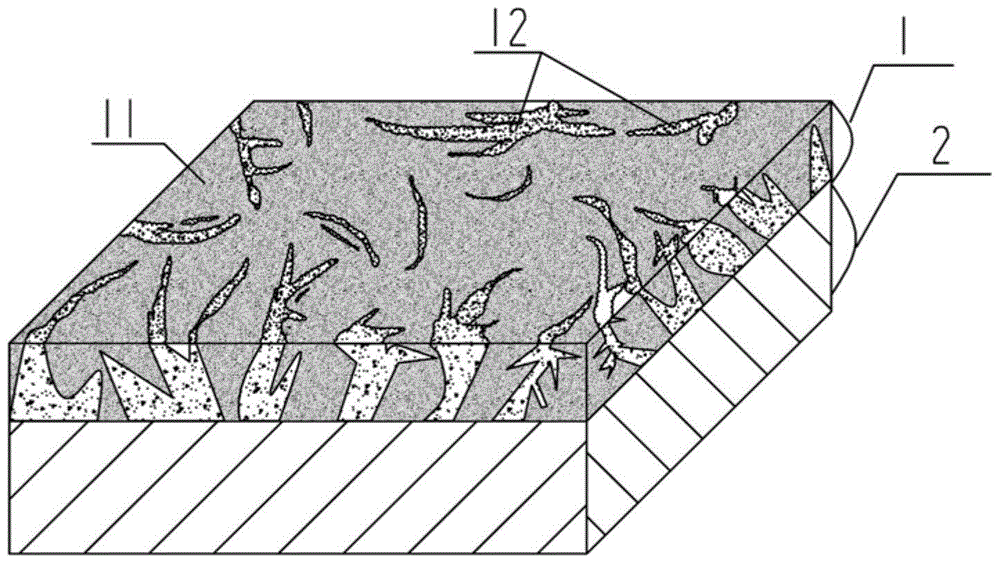

[0044] combine figure 1 , 2 , 3 and Figure 6 , a production method of a porcelain tile is described, the steps are as follows:

[0045] 1) Preparation of fabric pre-pressed layer: choose ordinary polished brick body powder, carry out ball milling and mixing, spray drying according to the preparation process of ordinary porcelain tile fabric, and lay a common fabric layer through the first material distributing device 61, and the fabric layer is pre-pressed Device 62 (belt rolling device) is pressed and formed to form a fabric pre-pressed layer 1 with a thickness of 4mm, and the bulk density of the fabric pre-pressed layer 1 is 0.9g / cm 3 ;

[0046] 2) Inkjet printing: Use the inkjet printing system 63 to print the penetrating ink on the fabric prepress layer 1 in step 1) according to the pattern requirements, and the penetrating effect formed after the ink seeps down and the original ceramic powder cloth effect are interlaced and superimposed, wherein the printing The pen...

Embodiment 2

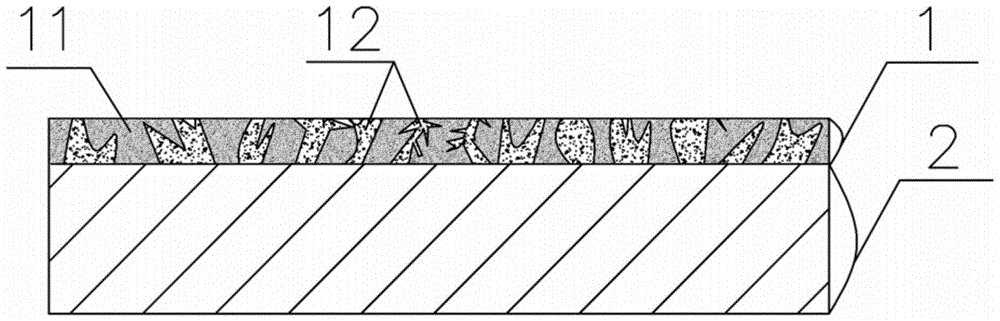

[0057] A method for producing porcelain tiles, the steps are as follows:

[0058] 1) Preparation of the fabric pre-pressed layer: select ordinary polished brick body powder to carry out ball milling, mixing and spray drying according to the preparation process of ordinary porcelain tile fabrics, and lay the first ordinary fabric layer through the first material distribution device 61, the fabric layer Pressed and formed by the pre-pressing device 62 to form a fabric pre-pressed layer 1 with a thickness of 7 mm and a bulk density of 1.1 g / cm 3 ;

[0059] 2) Inkjet printing: use the inkjet printing system 63 to print the penetrating ink on the pre-pressed layer of the fabric described in step 1) according to the pattern requirements. The ink is a combined aqueous solution of ferrous chloride, potassium chromate and nickel acetate.

[0060] 3) Secondary distributing: through the second distributing device 64, the ordinary porcelain tile body powder is laid on the ink printing s...

Embodiment 3

[0068] A method for producing porcelain tiles, the steps are as follows:

[0069] 1) Preparation of the fabric pre-pressed layer: select ordinary polished brick body powder to carry out ball milling, mixing and spray drying according to the preparation process of ordinary porcelain tile fabrics, and lay the first ordinary fabric layer through the first material distribution device 61, the fabric layer Pressed and formed by the pre-pressing device 62 to form a fabric pre-pressed layer with a thickness of 6mm and a bulk density of 1.0g / cm 3 ;

[0070] 2) Inkjet printing: use the inkjet printing system 63 to print the penetrating ink on the pre-pressed layer of the fabric described in step 1) according to the pattern requirements, and the penetrating effect formed after the ink seeps down and the original ceramic powder cloth effect are interlaced and superimposed, wherein the printing The penetrating ink is a combined aqueous solution of nickel acetate, zirconium hypochlorite a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com