Method for preparing polycrystalline aluminum oxide hard coating

A polycrystalline alumina, hard coating technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problem of poor mechanical properties of coatings, no application of grown oxide hard coatings, etc. problems, to achieve the effect of high hardness, good industrial application prospects, and simple and feasible technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

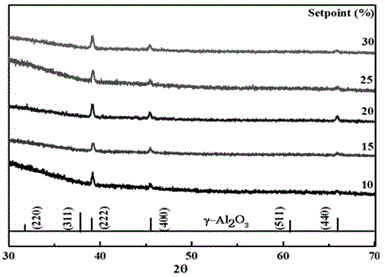

Image

Examples

Embodiment 1

[0023] Embodiment 1 Realize the present invention according to the following steps:

[0024] (1) Clamp the cleaned workpiece on the workpiece rack, turn on the vacuum system, and vacuum it. When the vacuum degree is higher than 5×10 -3 Pa, start heating and degassing, the temperature is controlled at 300 °C; the workpiece holder keeps rotating at 3 rpm, when the vacuum degree is 5×10 -3 At Pa, enter Ar gas, turn on the bias power supply, and perform glow cleaning on the workpiece. The vacuum is kept at 0.5 Pa, the bias voltage is 800V, and the glow time is 20 minutes;

[0025] (2) After glow cleaning, adjust the vacuum to 3×10 -1 Pa, turn on the unipolar pulse power supply (constant power mode) to sputter the aluminum target, bombard the workpiece for 5 minutes to form an aluminum metal bottom layer with a thickness of about 10 nm, keep the bias voltage at 600 V, and the duty cycle is 60%;

[0026](3) After the bombardment is completed, the bias voltage drops to 100V, the d...

Embodiment 2

[0028] Embodiment 2 realizes the present invention according to the following steps:

[0029] (1) Clamp the cleaned workpiece on the workpiece rack, turn on the vacuum system, and vacuum it. When the vacuum degree is higher than 5×10 -3 Pa, start heating and degassing, the temperature is controlled at 300 °C; the workpiece holder keeps rotating at 3 rpm, when the vacuum degree is 5×10 -3 At Pa, enter Ar gas, turn on the bias power supply, and perform glow cleaning on the workpiece. The vacuum is kept at 0.5 Pa, the bias voltage is 800V, and the glow time is 20 minutes;

[0030] (2) After glow cleaning, adjust the vacuum to 3×10 -1 Pa, turn on the unipolar pulse power supply (constant power mode) to sputter the aluminum target, bombard the workpiece for 5 minutes to form an aluminum metal bottom layer with a thickness of about 10 nm, keep the bias voltage at 600 V, and the duty cycle is 60%;

[0031] (3) After the bombardment is completed, the bias voltage is reduced to 100V...

Embodiment 3

[0033] Embodiment 3 realizes the present invention according to the following steps:

[0034] (1) Clamp the cleaned workpiece on the workpiece rack, turn on the vacuum system, and vacuum it. When the vacuum degree is higher than 5×10 -3 Pa, start heating and degassing, the temperature is controlled at 300 °C; the workpiece holder keeps rotating at 3 rpm, when the vacuum degree is 5×10 -3 At Pa, enter Ar gas, turn on the bias power supply, and perform glow cleaning on the workpiece. The vacuum is kept at 0.5 Pa, the bias voltage is 800V, and the glow time is 20 minutes;

[0035] (2) After glow cleaning, adjust the vacuum to 3×10 -1 Pa, turn on the unipolar pulse power supply (constant power mode) to sputter the aluminum target, bombard the workpiece with a thickness of about 10 nanometers of aluminum metal bottom layer for 5 minutes, keep the bias voltage at 600 V, and the duty cycle is 60%;

[0036] (3) After the bombardment is completed, the bias voltage is reduced to 100V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com