An improved two-inlet concentration gradient generator and its design method

A technology of concentration gradient and generator, which is applied in the application field to achieve the effect of low requirements, improved accuracy and improved resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

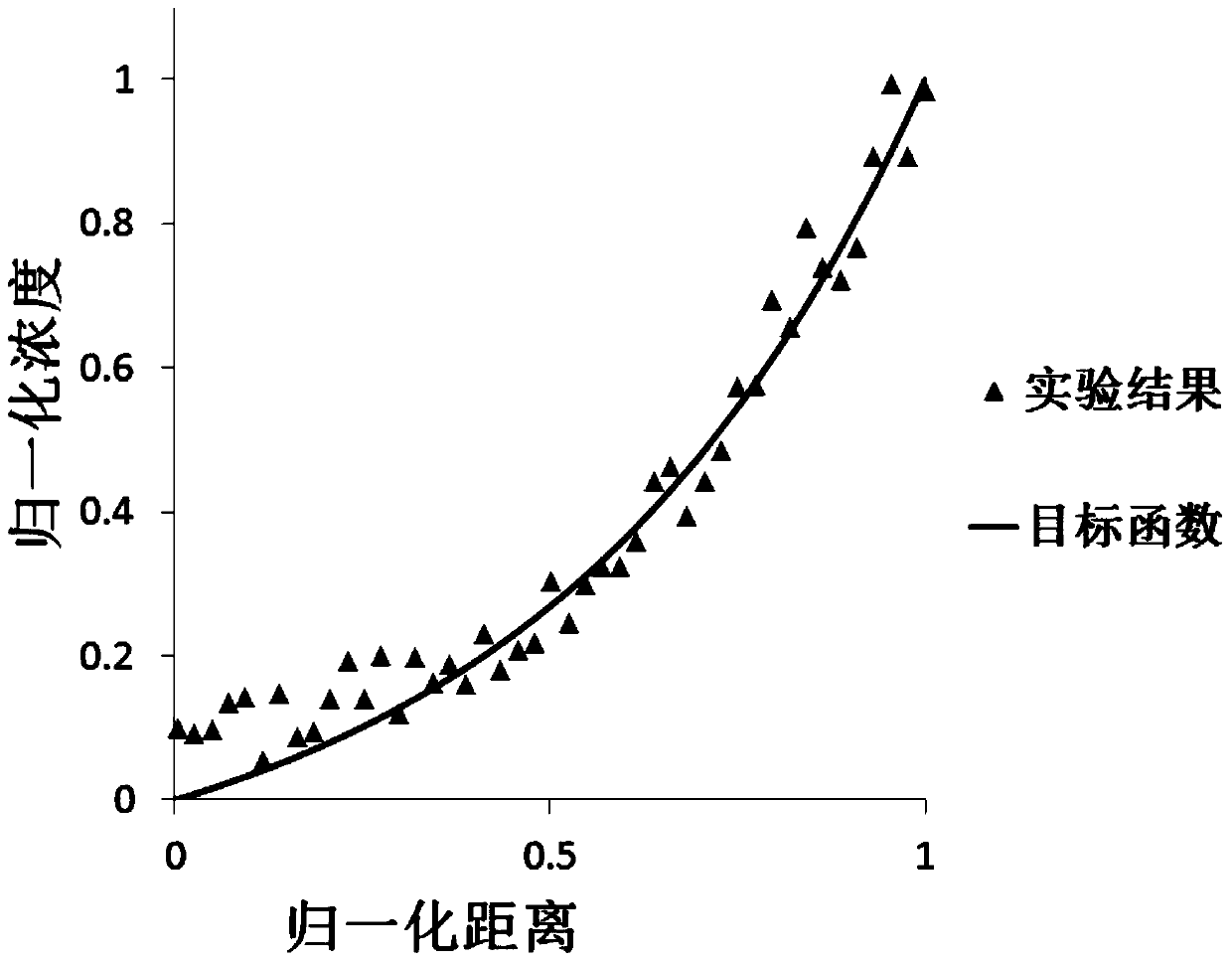

[0031] Embodiment 1: quadratic function y=x 2 Design of Concentration Gradient Generator

[0032] (1) The objective function itself has been normalized, that is, f(x)=x 2 . Take the resolution as 0.5, then according to α=0.5≥max{f((j+1) / 2 N-1 )-f(j / 2 N-1 )}, get N≥4, take N=4, then there are 4 levels in total, and there are 8 splitter plates in the 4th level.

[0033] (2) The width of the main channel of the concentration gradient generator is 400 μm. According to the principle of uniform distribution of the final distribution plate, the distances between the 8 distribution plates of the fourth level and the wall of the main channel can be calculated as 44.4, 88.9, 133.3, 177.8, 222.2, 266.7, 311.1, and 355.6 μm.

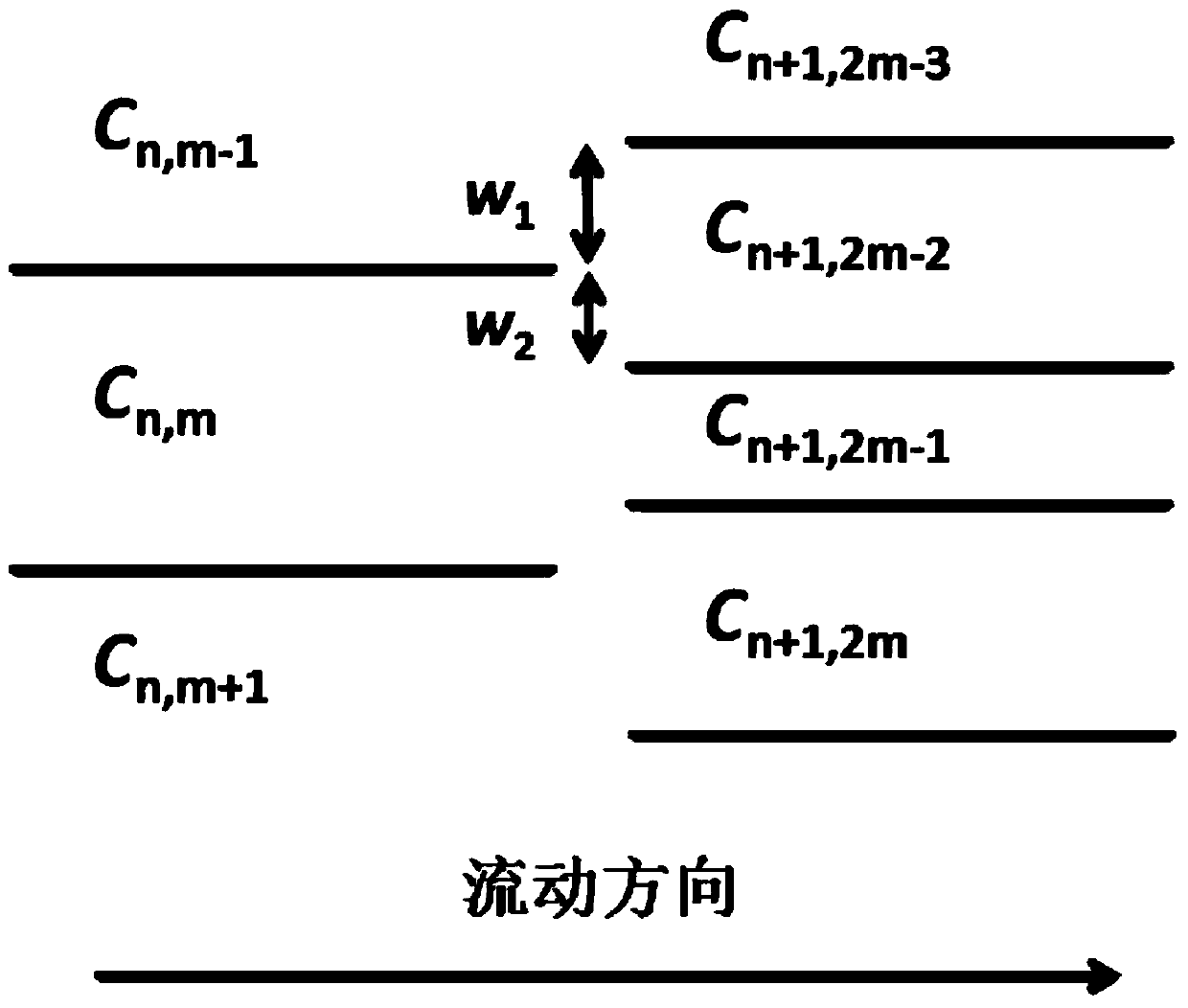

[0034] (3) According to C n,m =C n+1,2m-1 It can be seen that the concentration of the first channel of the third level C 3,1 =C 4,1 =f(0 / 2 3 )=0, the second channel concentration C 3,2 =C 4,3 =f(2 / 2 3 ) = 1 / 16. And the second channel concentration C o...

Embodiment 2

[0036] Embodiment 2: exponential function y=e 2x Design of Concentration Gradient Generator

[0037] (1) Normalize the objective function to f(x)=(e 2x -1) / (e 2 -1), take the resolution as 0.5, then according to α=0.5≥max{f((j+1) / 2 N-1 )-f(j / 2 N-1 )}, get N≥4, take N=4, then there are 4 levels in total, and there are 8 splitter plates in the 4th level.

[0038] (2) The width of the main channel of the concentration gradient generator is 400 μm. According to the principle of uniform distribution of the final distribution plate, the distances between the 8 distribution plates of the fourth stage and the wall of the main channel are calculated as 44.4, 88.9, 133.3, and 177.8, respectively. , 222.2, 266.7, 311.1 and 355.6 μm.

[0039] (3) According to C n,m =C n+1,2m-1 It can be seen that the concentration of the first channel of the third level C 3,1 =C 4,1 =f(0 / 2 3 )=0, the second channel concentration C 3,2 =C 4,3 =f(2 / 2 3 ) = 0.1015. And the second channel concen...

Embodiment 3

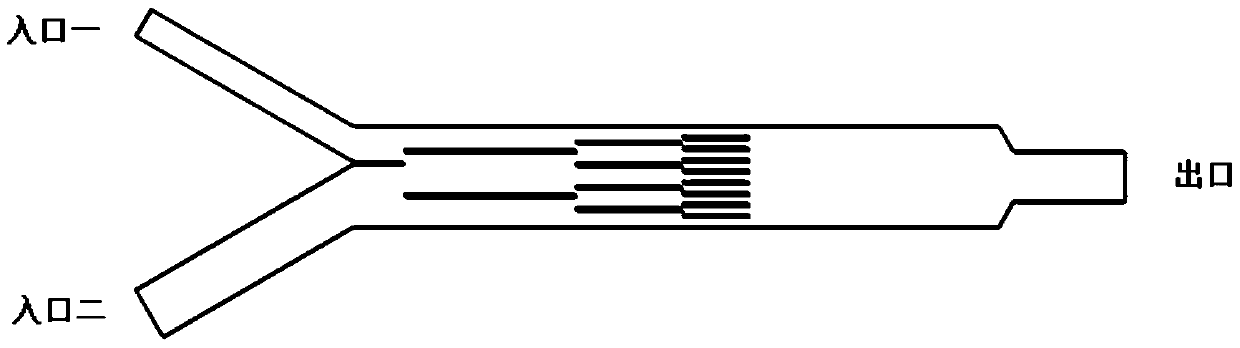

[0041] Embodiment 3: the preparation of two inlet concentration gradient generators

[0042] (1) Photolithography: Use AutoCAD to draw the microchannel pattern, then output the pattern to the film, and use standard photolithography technology to transfer the microchannel pattern to the silicon substrate template of SU-8 negative photoresist, and then forming a male mold patterned by microchannels;

[0043] (2) Pattern transfer: Mix the PDMS prepolymer and crosslinking agent evenly according to the mass ratio of 10:1, pour horizontally onto the SU-8 mold obtained by photolithography, put it in a vacuum box for 15 minutes to remove air bubbles, and then put Heat it in an oven at 70°C for 2 hours until it solidifies and take it out. Cut and peel off the PDMS, then use a hole punch to punch holes at the individual inlet and outlet channels;

[0044] (3) Bonding: The PDMS substrate with microstructure and the cleaned and dried glass cover slip are permanently bonded with a plasma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com