Polycarbonate composition, method for preparing same and application of polycarbonate composition

A technology of polycarbonate and composition, applied in the field of engineering plastics, to achieve the effect of low cohesion and good wear resistance

Active Publication Date: 2015-10-07

KINGFA SCI & TECH CO LTD

View PDF12 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] But, so far, with regard to adding perfluorinated polyolefin and perfluoroalkanoic acid and derivatives thereof to the polycarbonate composition in hydrolytic stability, wear resistance and resistance to polycarbonate composition The effect of flammability has not been reported

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

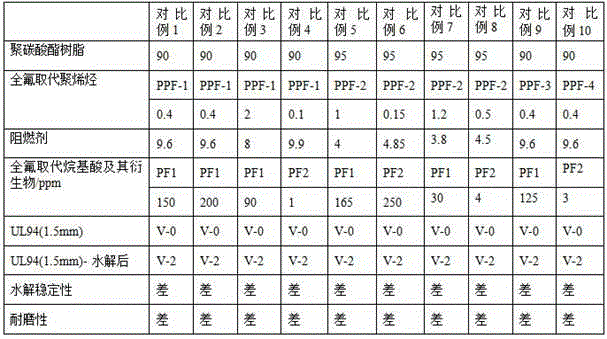

Embodiment 1-10 and comparative example 1-10

[0073] Embodiment 1-10 and comparative example 1-10: the preparation of polycarbonate composition

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a polycarbonate composition. The polycarbonate composition comprises, by weight, 86-99.5 parts of polycarbonate, 0.2-0.7 part of total-fluorine substituted polyolefin and 0.3-13.8 parts of flame retardant. The sum of the weights of the polycarbonate, the total-fluorine substituted polyolefin and the flame retardants is 100 parts. The polycarbonate composition has the advantages that specific quantities of the total-fluorine substituted polyolefin, total-fluorine substituted alkyl acid and derivatives of the total-fluorine substituted alkyl acid are selectively added into the polycarbonate composition in a formula, the total-fluorine substituted alkyl acid and the derivatives are based on the polycarbonate composition, the total weight of the total-fluorine substituted alkyl acid and the derivatives is 5ppm-100ppm, and accordingly, the hydrolysis stability, the abrasion resistance and the flame retardancy of the polycarbonate composition can be obviously improved; the polycarbonate composition is particularly applicable to the field of electronic and electrical appliances.

Description

technical field [0001] The invention relates to the technical field of engineering plastics, in particular to a polycarbonate composition and its preparation method and application. Background technique [0002] Polycarbonate is a tough thermoplastic resin, the second largest engineering plastic after polyamide in output. Polycarbonate is heat-resistant, impact-resistant, and has good mechanical properties at normal operating temperatures. It is widely used in automobiles , electronics, electrical appliances, construction, office equipment, packaging and other fields. [0003] However, due to the high requirements for flame retardancy of materials in electronics, electrical appliances, construction, and office equipment, polycarbonate must be treated with flame retardancy. In addition, polycarbonate has high hygroscopicity, and it is easy to produce bubbles and silver streaks during processing. The product is prone to residual internal stress and is highly sensitive to notc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L69/00C08L27/18C08K5/095C08K5/42C08G64/06

CPCC08G64/06C08K5/095C08K5/42C08L27/18C08L69/00C08L2201/02C08L2201/08C08L2203/20

Inventor 杨燕何继辉佟伟孙东海

Owner KINGFA SCI & TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com