Carbon-based composite with high rebound resilience and high heat conductivity coefficient along thickness direction and preparation method of carbon-based composite

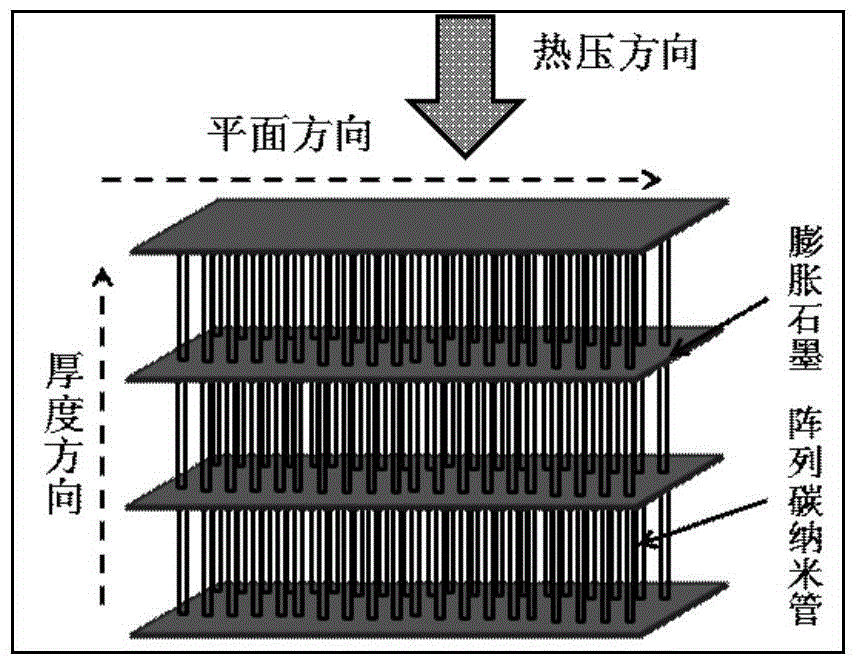

A technology of carbon-based composite materials and thickness direction, which is applied in the field of carbon-based composite materials with high resilience and high thermal conductivity along the thickness direction and its preparation. It can solve the problems of low thermal conductivity and poor resilience of graphite heat-conducting sheets, and achieve growth shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

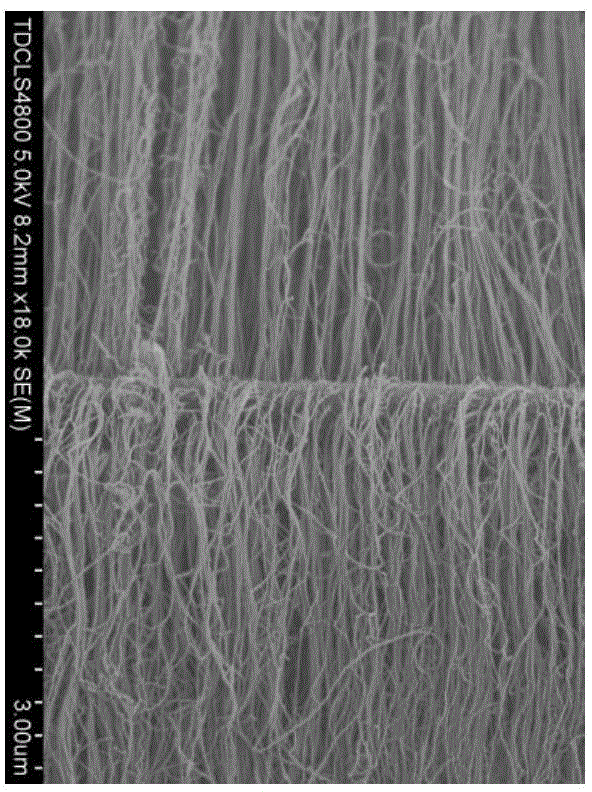

[0024] Select 1.8 g and 18 g of absolute ethanol and xylene respectively to prepare a carbon source solution, and add 0.2 g of ferrocene to the carbon source solution to prepare a ferrocene carbon source solution with a mass fraction of 1%. Place expanded graphite with an expansion rate of 100 in a tube furnace, pass through argon protection, heat the tube furnace to 700°C, inject the above-mentioned ferrocene carbon source solution, and the injection speed of the ferrocene carbon source solution is The growth time was controlled at 10mL / h, and the growth time was 120min. After the growth, stop injecting the ferrocene carbon source solution, and take it out after cooling to room temperature under the protection of inert gas. The expanded graphite with carbon nanotubes growing arrays is placed in a graphite mold and placed in a vacuum hot-press furnace for high-temperature hot-pressing. The heating rate is 200°C / h, the hot-pressing temperature is 1500°C, and the hot-pressing pre...

Embodiment 2

[0026] 9.5 g of absolute ethanol and xylene were selected to form a carbon source solution, and 1 g of ferrocene was added to the carbon source solution to form a ferrocene carbon source solution with a mass fraction of 5%. Place expanded graphite with an expansion rate of 300 in a tube furnace, pass through argon protection, heat the tube furnace to 900°C, inject the above-mentioned ferrocene carbon source solution, and the injection speed of the ferrocene carbon source solution is Control at 30mL / h, growth time is 30min, stop injecting ferrocene carbon source solution after growth, and cool to room temperature under the protection of inert gas to take out. The expanded graphite growing arrayed carbon nanotubes is placed in a graphite mold and placed in a vacuum hot-press furnace for high-temperature hot-pressing. The heating rate is 300°C / h, the hot-pressing temperature is 2000°C, and the hot-pressing pressure is 40MPa. After 1h, when the temperature dropped to 100°C, the pr...

Embodiment 3

[0028]9.6 g of absolute ethanol and xylene were selected to form a carbon source solution, and 0.8 g of ferrocene was added to the carbon source solution to form a ferrocene carbon source solution with a mass fraction of 4%. Place expanded graphite with an expansion rate of 200 in a tube furnace, pass through argon protection, heat the tube furnace to 800°C, inject the above-mentioned ferrocene carbon source solution, and the injection speed of the ferrocene carbon source solution is The growth time was controlled at 20mL / h, and the growth time was 60min. After the growth, stop injecting the ferrocene carbon source solution, and take it out after cooling to room temperature under the protection of inert gas. The expanded graphite with carbon nanotubes growing arrays is placed in a graphite mold, placed in a vacuum hot-press furnace for high-temperature hot-pressing, the heating rate is 260°C / h, the hot-pressing temperature is 1600°C, and the hot-pressing pressure is 30MPa. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com