Light sound insulation damping mortar and building construction method

A technology of damping sand and light sand, which is used in the field of building materials, can solve the problems of the impact sound pressure level not meeting the design requirements of the specification, the destruction of sound bridges and sound insulation pads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Choose from the following proportions:

[0030] 42.5R cement 30%

[0031] Fly Ash 4.0%

[0032] Rubber 5.0%

[0033] Bottom slag 53%

[0034] Vitrified microbeads 6.7%

[0035] Latex powder 1%

[0037] PP fiber 0.15%,

[0038] Mix evenly according to the above percentage example, add an appropriate amount of water and stir evenly in a mixer, and perform a performance index test. The test data is as follows:

[0039] Apparent density: 651kg / m 3 , Tensile bond strength: 0.18Mpa, compressive strength: 3.8Mpa, linear shrinkage: 0.14%, thermal conductivity: 0.118W / m.k.

[0040] Take the 30mm thick lightweight sound insulation and damping mortar with this ratio and spread it on the reinforced concrete floor to test the impact sound improvement. The impact sound improvement is 17dB.

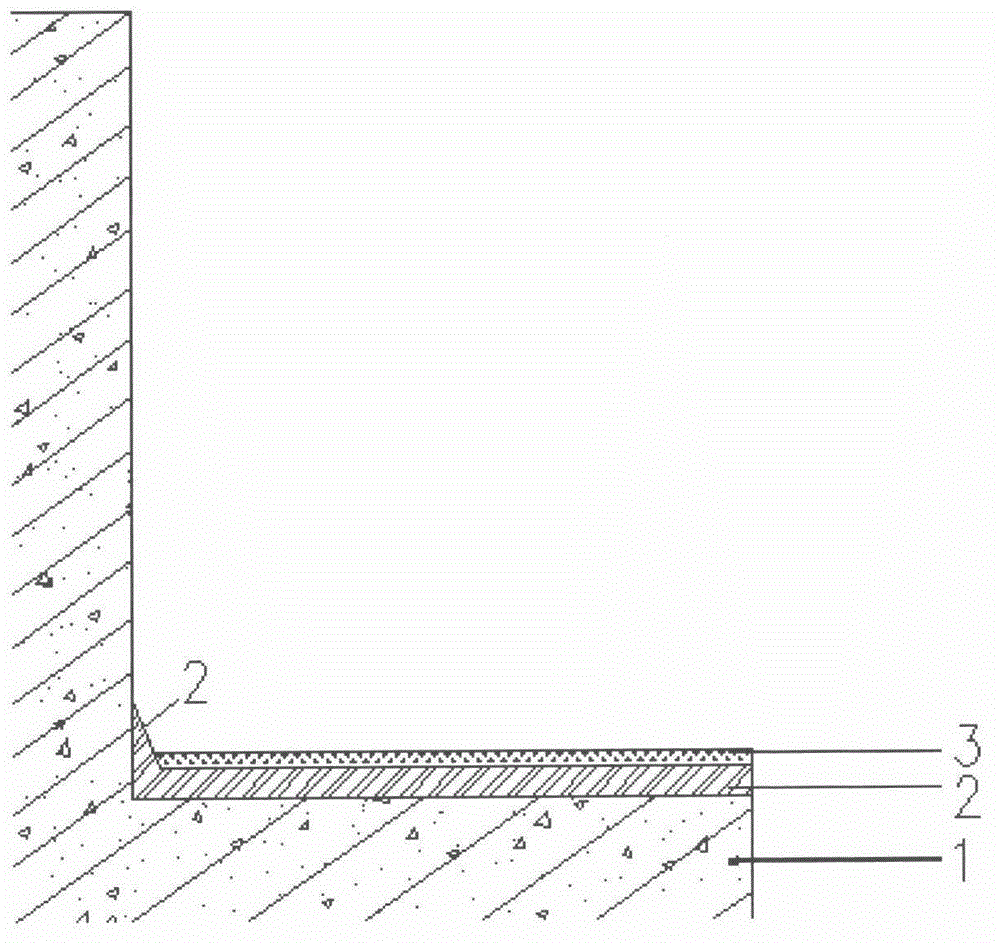

[0041] Select the above-mentioned lightweight sound-proof damping mortar and apply it to the 120mm thick reinforced concrete floor: design structure 1 is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com