Sound insulation terrace mortar, preparation method thereof and sound insulation terrace construction method

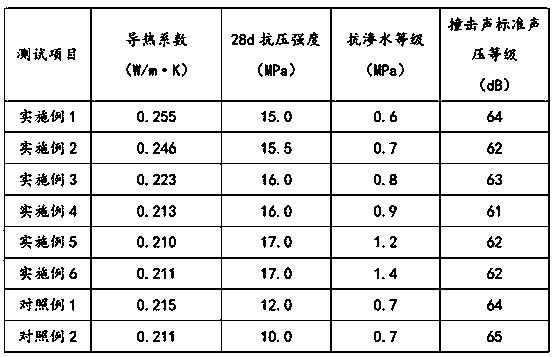

A construction method and floor technology, applied in the field of building decoration materials, can solve the problems of low strength, insufficient strength to adapt to the long-term load-bearing and wear resistance of the floor, so as to increase the compressive strength, improve the anti-seepage performance, The effect of meeting diverse needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of soundproof floor mortar, its raw material ratio is as follows:

[0057] α gypsum 80kg

[0058] Volcanic rock lightweight aggregate 10kg

[0059] Sodium polyacrylate 0.5kg

[0060] Sodium citrate 0.5kg;

[0061] Among them, the selected volcanic rock light aggregate density is 200㎏ / m 3 , The strength is 1MPa.

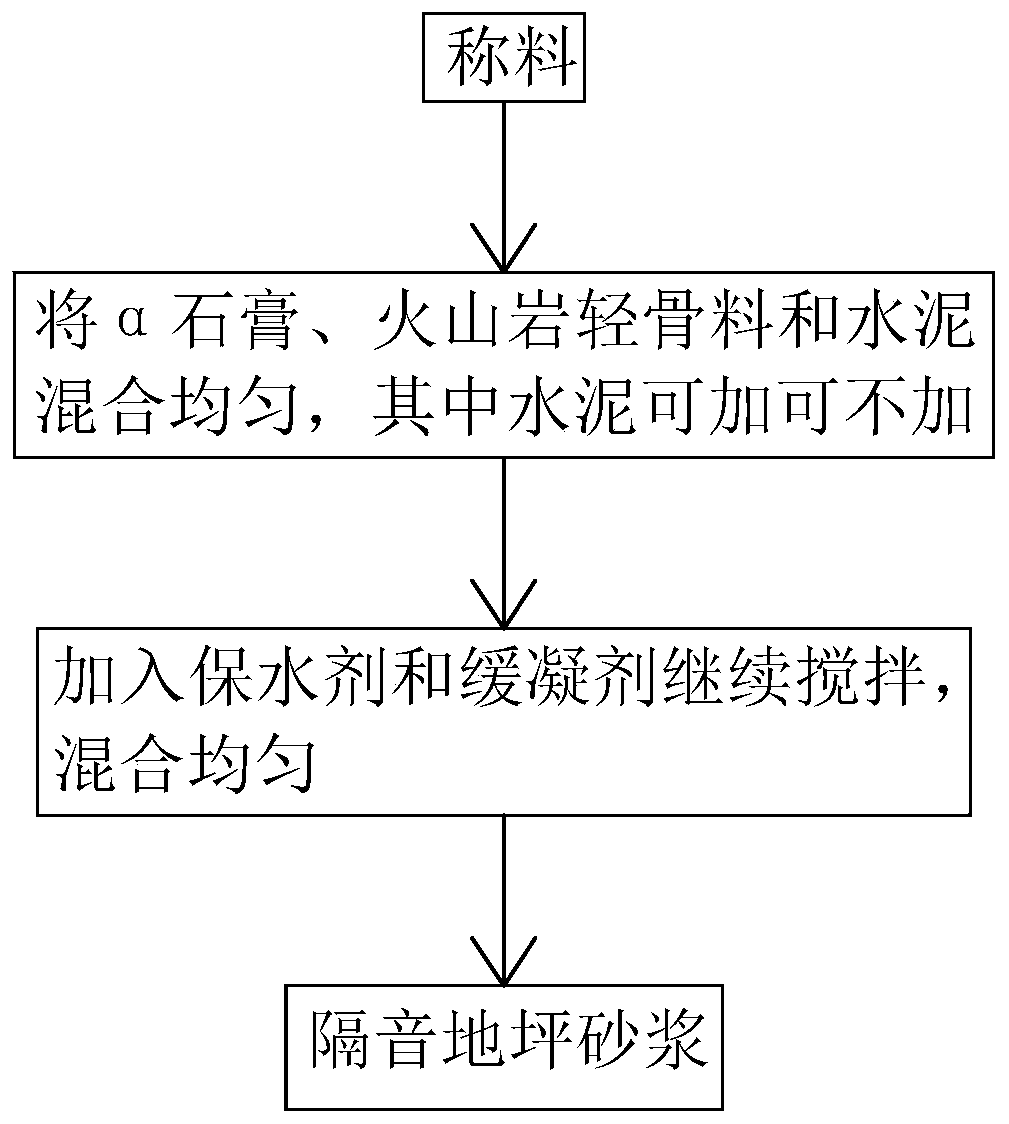

[0062] Its preparation method refers to figure 1 The process flow shown proceeds:

[0063] Weigh according to the above ratio, first add the weighed α gypsum and volcanic rock light aggregate to the mixing equipment, stir and mix evenly; then add the weighed sodium polyacrylate and sodium citrate and continue stirring, mix evenly to get the soundproof floor mortar .

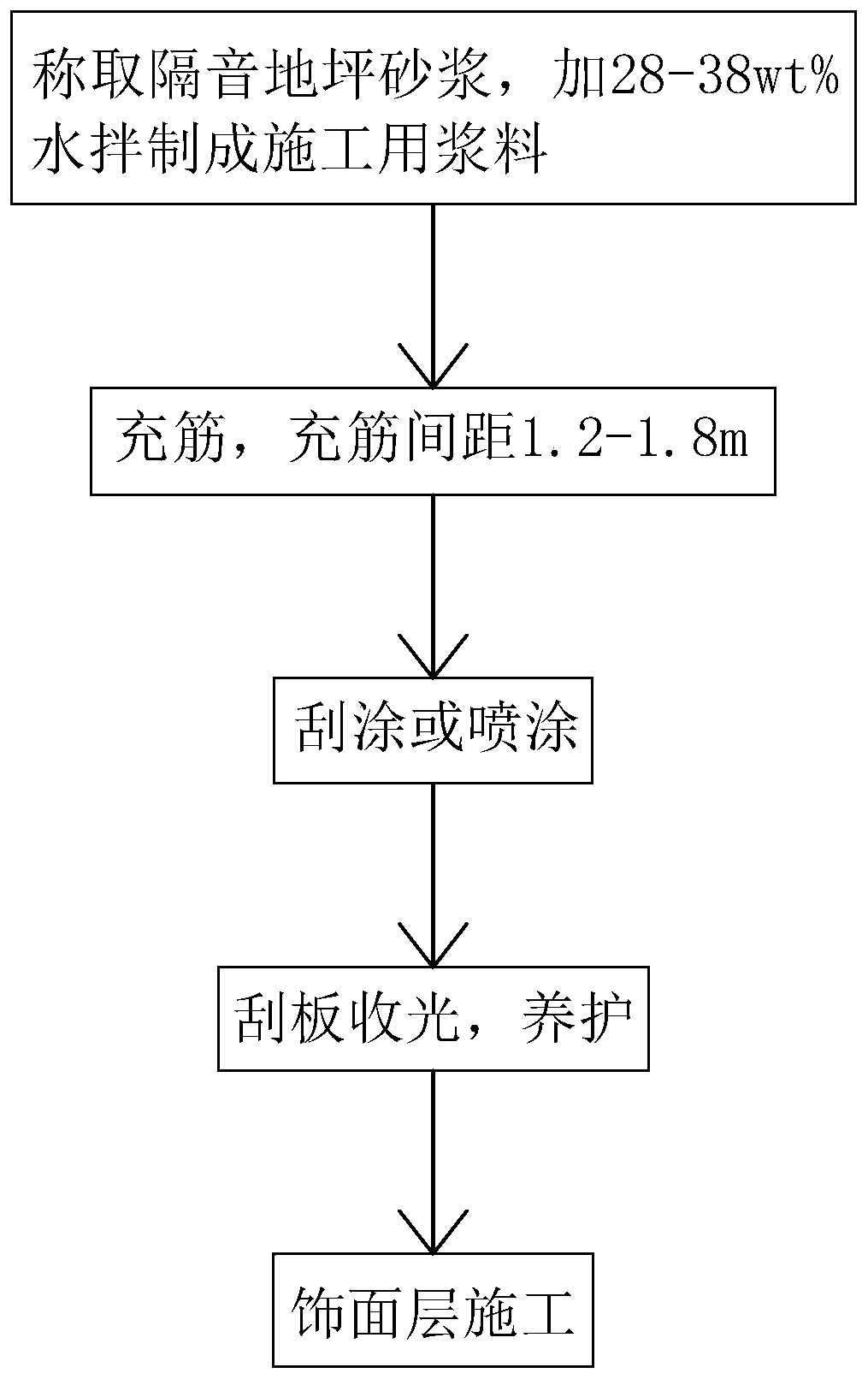

[0064] How to use: Add 28wt% water to the sound-proof floor mortar, mix it to make a uniform paste, and then apply it by scraping or spraying.

Embodiment 2

[0066] A kind of soundproof floor mortar, its raw material ratio is as follows:

[0067] α gypsum 84kg

[0068] Volcanic rock lightweight aggregate 14kg

[0069] Sodium starch grafted acrylate 1.0kg

[0070] Sodium citrate 1.5kg;

[0071] Among them, the selected volcanic rock light aggregate density is 300㎏ / m 3 , The strength is 3MPa.

[0072] Its preparation method refers to figure 1 The process flow shown proceeds:

[0073] Weigh according to the above ratio, first add the weighed α gypsum and volcanic rock light aggregate to the mixing equipment, stir and mix evenly; then add the weighed starch-grafted sodium acrylate and sodium citrate and continue stirring, mix evenly to get the soundproof floor Ping mortar.

[0074] How to use: Add 32wt% water to the sound-proof floor mortar, mix it to make a uniform paste, and then apply it by scraping or spraying.

Embodiment 3

[0076] A kind of soundproof floor mortar, its raw material ratio is as follows:

[0077] α gypsum 88kg

[0078] Volcanic rock lightweight aggregate 18kg

[0079] Hydroxyethyl Cellulose 2.0kg

[0080] Sodium citrate 2.0kg;

[0081] Among them, the selected volcanic rock light aggregate density is 400㎏ / m 3 , The strength is 4MPa.

[0082] Its preparation method refers to figure 1 The process flow shown proceeds:

[0083] Weigh according to the above ratio, first add the weighed α gypsum and volcanic rock light aggregate to the mixing equipment, stir and mix evenly; then add the weighed hydroxyethyl cellulose and sodium citrate and continue stirring, mix evenly to get the soundproof floor Ping mortar.

[0084] How to use: Add 36wt% clear water to the sound-proof floor mortar, mix it to make a uniform paste, and then apply it by scraping or spraying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com