Tower bottom hydraulic contact pin breakage dust-free ash discharge device and application method thereof

A technology of pin insertion and hydraulic pressure, which is applied in the field of ash release device, hydraulic pin crushing and dust-free ash release device at the bottom of the tower, which can solve the problems of blocking the discharge port, etc., achieve the effects of reducing dust, simple and convenient operation, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

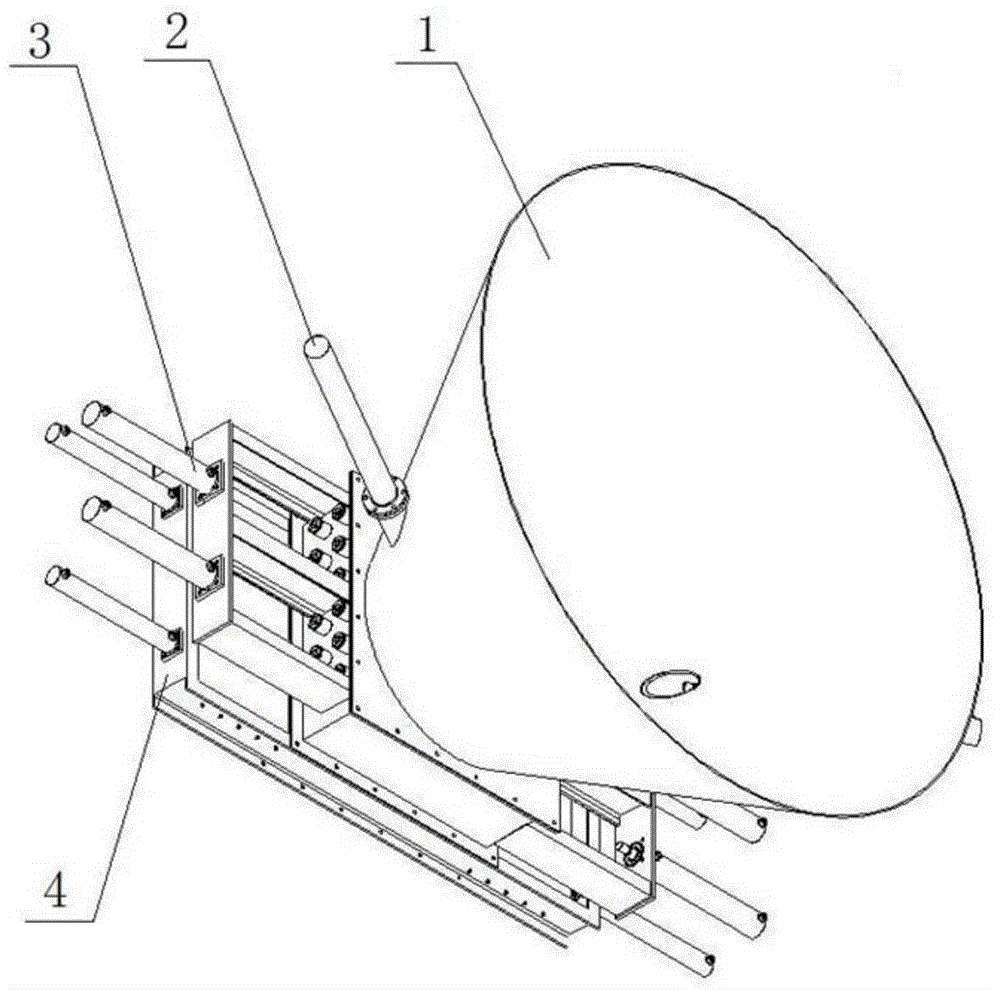

[0027] This embodiment provides a device for crushing and dust-free ash discharge of hydraulic pins at the bottom of the tower, the structure of which is as follows: figure 1 , figure 2 As shown, it includes a funnel-shaped desulfurization tower silo 1 and a bottom hydraulic flashboard 4. The bottom hydraulic flashboard 4 is a symmetrically arranged two-way flashboard. Two-way four-row pins, the two-way four-row pins are symmetrically provided with two rows of pins on both sides, the top of the flat pin 3 is connected to the bottom outlet of the desulfurization tower silo 1, and two symmetrically installed on the side wall of the desulfurization tower silo 1 An inclined pin 2, the acute angle between the pin 2 and the side wall of the desulfurization tower silo 1 is 15-75°; the bottom hydraulic insert 4 is provided with a tower bottom dust cover 7, and the tower bottom dust cover 7 is on both sides A first dust removal pipeline 5 and a second dust removal pipeline 6 are resp...

Embodiment 2

[0031] This embodiment provides an application method of a hydraulic pin crushing and dust-free ash discharge device at the bottom of the tower. The method is as follows:

[0032] (1) Install two-way four-row pins above the bottom hydraulic plug-in board with two-way plug-in board, and two rows of plug-in pins are symmetrically arranged on both sides, and two inclined pins are symmetrically installed on the side wall of the desulfurization tower silo. Hydraulic pin;

[0033] (2) When the ash discharge device is working, when there is a large block at the bottom of the tower blocking the discharge port, stop the truck at the discharge port, and notify the central control room to open the dampers of the two additional fans to 100%, and raise the first dust removal pipe and the second 2. The negative pressure of the dust removal pipeline;

[0034](3) Close the valve port of the hydraulic insert plate at the bottom, insert two rows of pins on each side into the bottom of the desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com