Combustor of inner flame gas range

A technology for burners and gas stoves, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems that the heat flow is difficult to meet the needs of the market, it is difficult to avoid clogging the fire holes, and the air supplement is difficult. The effect of large flow, meeting market demand and fierce firepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] The implementation manners of several typical structural embodiments in the present invention are as follows:

[0040] (1) The structure of the single-cavity fire distributor device without air passage

[0041] Implementation of the first exemplary embodiment:

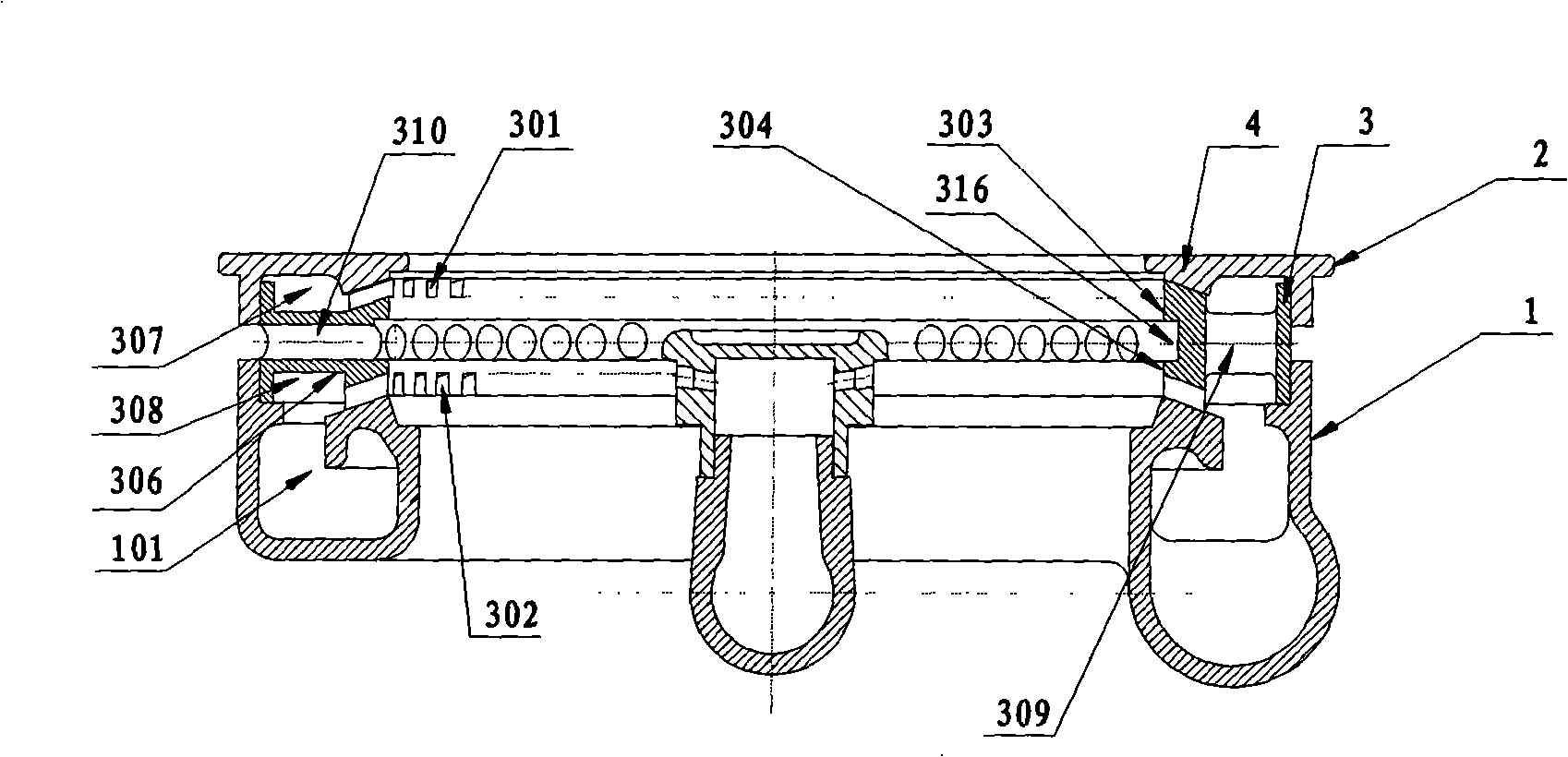

[0042] On the fire distributor device, upper and lower layers of fire holes 301, 302 are arranged along the inner circumference of the fire distributor main body, and the fire hole outlet direction is inward; The fire hole is arranged at the bottom of the cylindrical section 304 of the inner ring of the main body of the fire distributor; the section of the fire hole is trapezoidal, rectangular or strip-shaped; the cylindrical section where the upper fire hole is located is directly connected to the cylindrical section where the lower fire hole is located; in the main body of the fire distributor, A separation layer 306 is provided between the upper and lower fire holes, and the inner cavity of the main body of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com