A load cu/cu 2 oReduced graphene oxide/amorphous carbon composite material of photocatalyst and its preparation method and application

An amorphous carbon and photocatalyst technology, applied in the field of composite materials, can solve the problems of limited types of organic substances, high processing cost, unfavorable industrialization promotion, etc., and achieves good visible light absorption characteristics, good hydrophilicity and wide application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

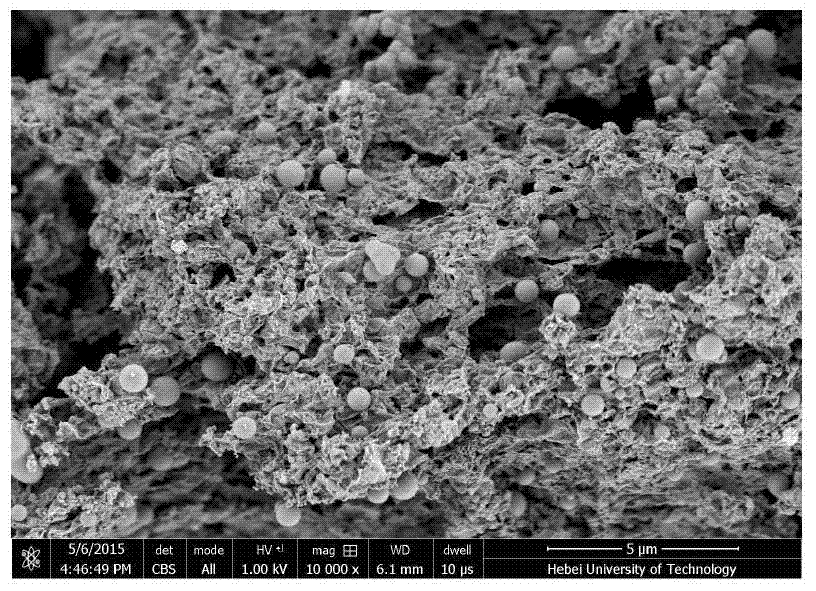

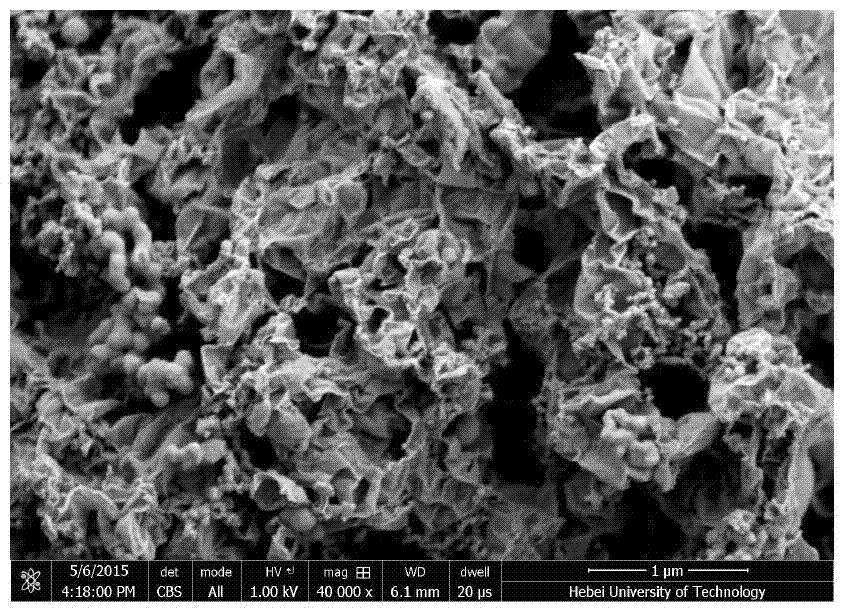

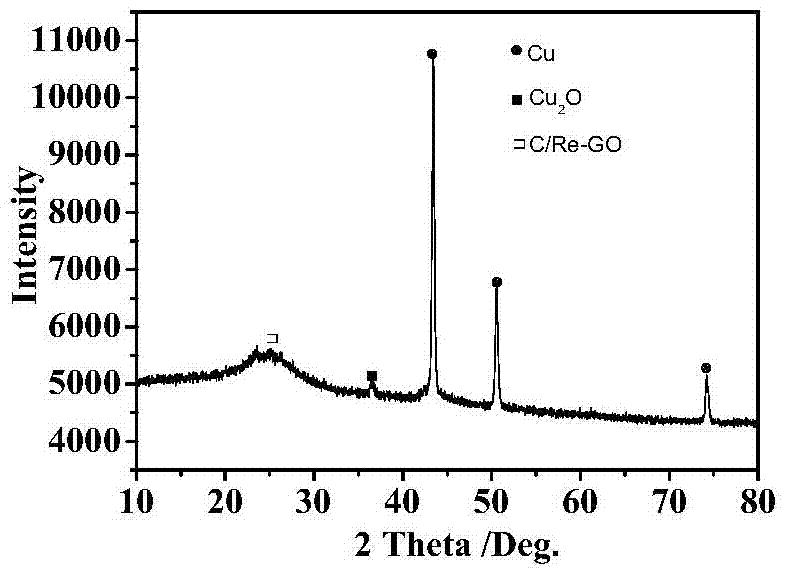

[0033] (1) Preparation of reduced graphene oxide / amorphous carbon substrate dispersion: dissolve glucose in an aqueous solution of graphene oxide, and stir at room temperature for 2 hours to obtain a mixed solution of graphene oxide and sugar, wherein: the sugar solution in the mixed solution The concentration of the graphene solution is 10mg / mL, and the concentration of the graphene solution is 0.3mg / mL. The mixture is poured into an autoclave, subjected to a hydrothermal reaction at 180°C for 6 hours, and cooled naturally to room temperature to obtain reduced graphene oxide / free Shaped carbon based dispersions;

[0034] (2) Load Cu / Cu 2 The preparation of the reduced graphene oxide / amorphous carbon composite material of O photocatalyst: a certain amount of copper sulfate is added in the reduced graphene oxide / amorphous carbon substrate dispersion liquid prepared in step 1 (per mL reduced graphene oxide / Add 0.002g of copper sulfate to the amorphous carbon substrate dispersi...

Embodiment 2

[0037] (1) Preparation of reduced graphene oxide / amorphous carbon substrate dispersion: dissolve konjac starch in an aqueous solution of graphene oxide, stir at 60° C. for 2 hours, and cool to room temperature naturally to obtain a mixed solution of graphene oxide and sugar, Among them: the concentration of the sugar solution is 10 mg / mL, the concentration of the graphene solution is 0.3 mg / mL, the mixture is poured into an autoclave, subjected to a hydrothermal reaction at 180°C for 16 hours, and naturally cooled to room temperature to obtain the reduction oxidation Graphene / amorphous carbon substrate dispersion;

[0038] (2) Load Cu / Cu 2 The preparation of the reduced graphene oxide / amorphous carbon composite material of O photocatalyst: a certain amount of copper acetate is added in the reduced graphene oxide / amorphous carbon substrate dispersion liquid prepared in step 1 (per mL reduced graphene oxide / Add 0.002g of copper acetate to the amorphous carbon substrate dispers...

Embodiment 3

[0041] (1) Preparation of reduced graphene oxide / amorphous carbon substrate dispersion: dissolve cornstarch in an aqueous solution of graphene oxide, stir at 100°C for 2 hours, and cool to room temperature naturally to obtain a mixed solution of graphene oxide and sugar, Among them: the concentration of the sugar solution is 10 mg / mL, the concentration of the graphene solution is 0.3 mg / mL, the mixture is poured into an autoclave, and subjected to a hydrothermal reaction at 180°C for 24 hours, and naturally cooled to room temperature to obtain the reduction oxidation Graphene / amorphous carbon substrate dispersion;

[0042] (2) Load Cu / Cu 2 The preparation of the reduced graphene oxide / amorphous carbon composite material of O photocatalyst: a certain amount of copper acetate is added in the reduced graphene oxide / amorphous carbon substrate dispersion liquid prepared in step 1 (per mL reduced graphene oxide / Add 0.002g of copper acetate to the amorphous carbon substrate dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com