Catalyst and application thereof

A catalyst, catalyst quality technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, bulk chemical production, etc., to achieve good low-temperature catalytic activity, reduce gasification temperature, and overcome corrosiveness strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

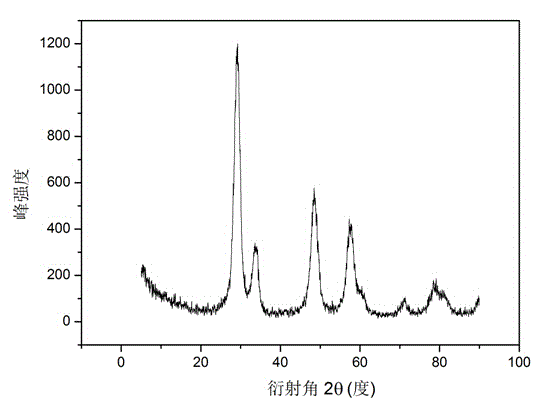

Image

Examples

Embodiment 1

[0027] Embodiment 1: The catalyst of this embodiment uses cerium-zirconium solid solution as a carrier, metal ruthenium as an active component, ruthenium in the catalyst accounts for 0.5% of the catalyst mass, and the molar ratio of cerium to zirconium in the cerium-zirconium solid solution carrier is 4: 1;

[0028] The preparation steps of this catalyst are as follows:

[0029] (1) Add polyethylene glycol in distilled water and stir until completely dissolved, the concentration of polyethylene glycol solution is 10 g / L;

[0030] (2) Add a mixture of cerium nitrate and zirconium nitrate to the solution in step (1), stir at a constant temperature of 80°C until completely dissolved, wherein the molar concentration of total metal ions of cerium and zirconium in the solution is 0.1 mol / L, cerium nitrate and nitric acid Zirconium is mixed with a molar ratio of cerium and zirconium of 4:1;

[0031] (3) Add ammonia water drop by drop to the solution in step (2) and stir, adjust the ...

Embodiment 2

[0037]Embodiment 2: The catalyst of this embodiment uses cerium-zirconium solid solution as the carrier, metal ruthenium as the active component, ruthenium in the catalyst accounts for 1.0% of the mass of the catalyst, and the molar ratio of cerium to zirconium in the cerium-zirconium solid solution carrier is 3:1;

[0038] The preparation steps of this catalyst are as follows:

[0039] (1) Add polyethylene glycol in distilled water and stir until completely dissolved, the concentration of polyethylene glycol solution is 20g / L;

[0040] (2) Add a mixture of cerium chloride and zirconium nitrate to the solution in step (1), stir at a constant temperature of 30°C until completely dissolved, wherein the molar concentration of total metal ions of cerium and zirconium in the solution is 0.2 mol / L, and cerium chloride Mix with zirconium nitrate in a molar ratio of 3:1 to cerium to zirconium;

[0041] (3) Add ammonia water drop by drop to the solution in step (2) and stir. After adj...

Embodiment 3

[0046] Embodiment 3: The catalyst of this embodiment uses cerium-zirconium solid solution as a carrier, metal ruthenium as an active component, ruthenium in the catalyst accounts for 2.5% of the mass of the catalyst, and the molar ratio of cerium to zirconium in the cerium-zirconium solid solution carrier is 2:1;

[0047] The preparation steps of this catalyst are as follows:

[0048] (1) Add polyethylene glycol in distilled water and stir until completely dissolved, the concentration of polyethylene glycol solution is 15g / L;

[0049] (2) Add the mixture of cerium chloride and zirconium sulfate to the solution in step (1), stir at a constant temperature of 50°C until completely dissolved, wherein the molar concentration of total metal ions of cerium and zirconium in the solution is 0.15 mol / L, cerium chloride Mix with zirconium sulfate in the ratio of cerium to zirconium molar ratio 2:1;

[0050] (3) Add ammonia water drop by drop to the solution in step (2) and stir. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com