Round bend type transformer tank cover

A transformer box and transformer technology, applied in the field of transformer manufacturing, can solve problems such as low cost of the box cover, reduced transformer sealing performance, and aging of the sealing strip, and achieve the effects of reasonable bending size design, reduced damage, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

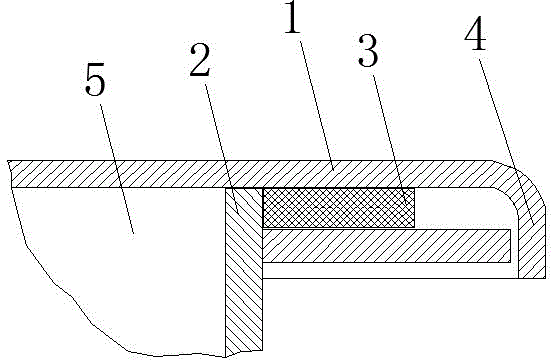

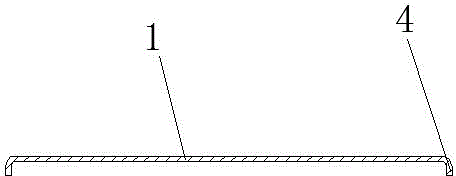

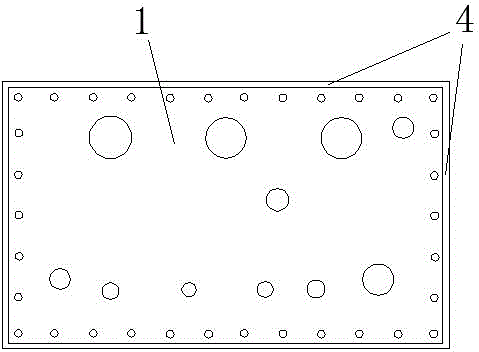

[0023] Such as figure 1 , figure 2 , image 3 As shown, a round corner bending type transformer box cover 1 is used for the transformer box body 5. The transformer box cover 1 covers the transformer box body 5 and is a square cover plate. The four sides of the box cover 1 are all located at On the outer side of the side wall 2 of the transformer box, the four edges of the box cover 1 are rounded and bent downward to form four ribs 4, and the bent parts of the cover plate forming the ribs 4 are all located outside the side wall 2 of the transformer box On the side, the four ribs are connected as a whole through welding on the outer surface of the box cover and the seams are eliminated.

[0024] The thickness of the box cover 1 is 4 mm. After bending, each side of the box cover 1 extends out of the transformer box by 9 mm. The edges of the box cover 1 are vertically bent with R4 rounded corners, and the bending length is 20 mm.

[0025] The manufacturing process of the box c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com