Novel coring and paraffin-removing method for coiled tubing in low-pressure low-yield oil-gas well

A technology for oil and gas wells and a new method, which is used in earth-moving drilling, cleaning equipment, wellbore/well components, etc., can solve the problem of inability to establish wellbore wax blocking profiles, difficulties in wax removal and prevention research, and unsuitable oil and gas wells. and other problems, to achieve the effect of high wax removal efficiency, obvious wax removal effect, and no formation pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

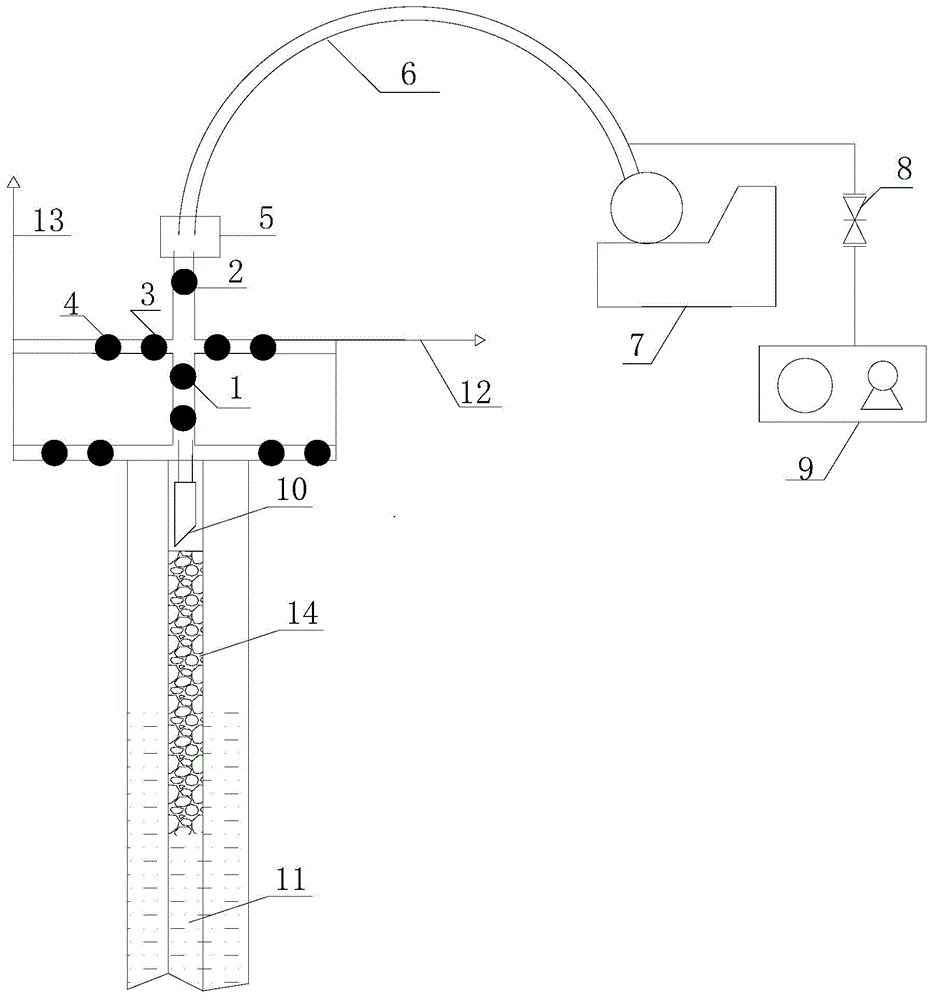

[0018] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

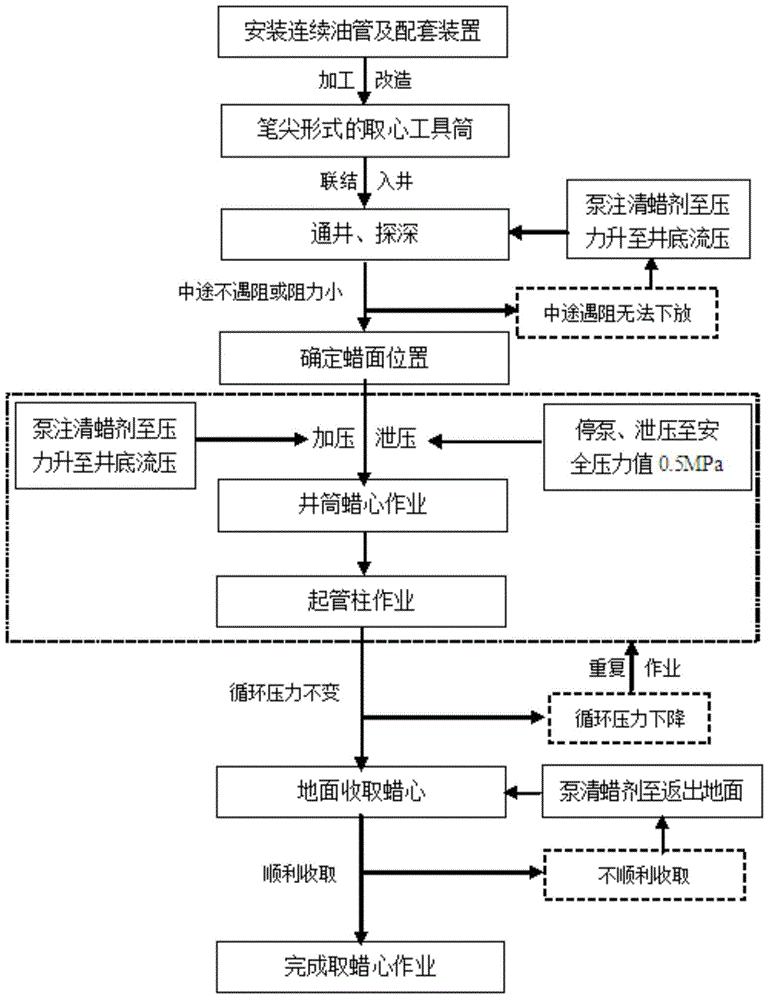

[0019] The present invention provides a new wax removal method for coiled tubing coring of low-pressure and low-yield oil and gas wells, which utilizes the technical characteristics of mechanical wax removal and chemical wax removal, and combines the working principle of drilling and coring, including the following steps:

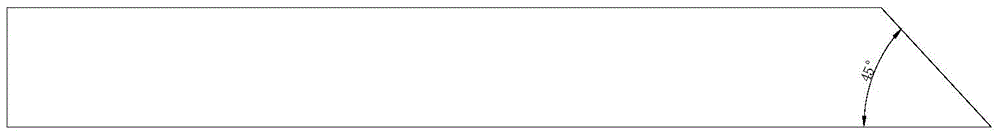

[0020] 1) Close the main valve 1 of the gas tree, the first-level needle valve 3 on the left wing, and the first-level gate valve 4 on the left wing (all other valves on both wings of the gas tree are also closed), open the wax removal valve 2, and install the blowout prevention device according to the requirements for coiled tubing operations 5; At the same time, use a high-pressure pipeline to connect the initial end of the coiled tubing 6 with an outer diameter of φ88.9mm to the process control needle valve 8 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com