Solid cylindrical fabric and weaving method thereof

A technology of cylinders and fabrics, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of low torsional strength, structural damage, skin-core detachment of composite solid shafts, etc., and achieve strong designability of mechanical properties, Good anti-torsion performance and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

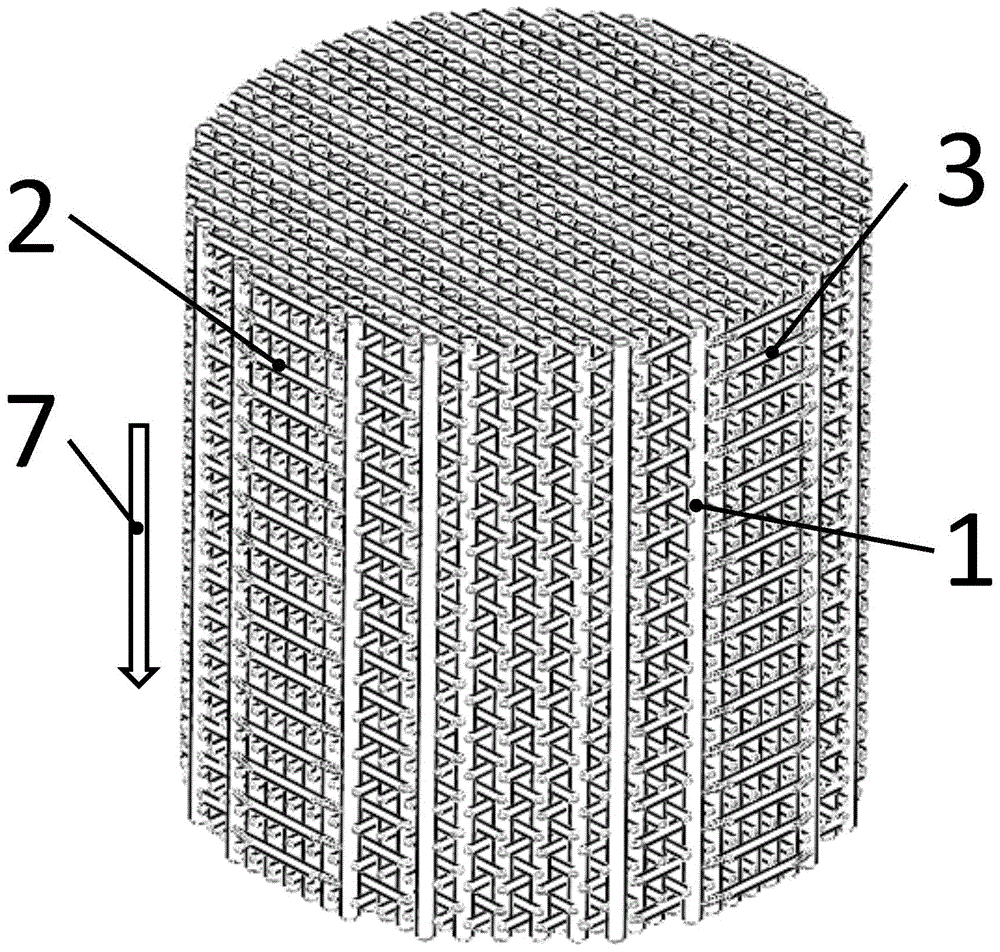

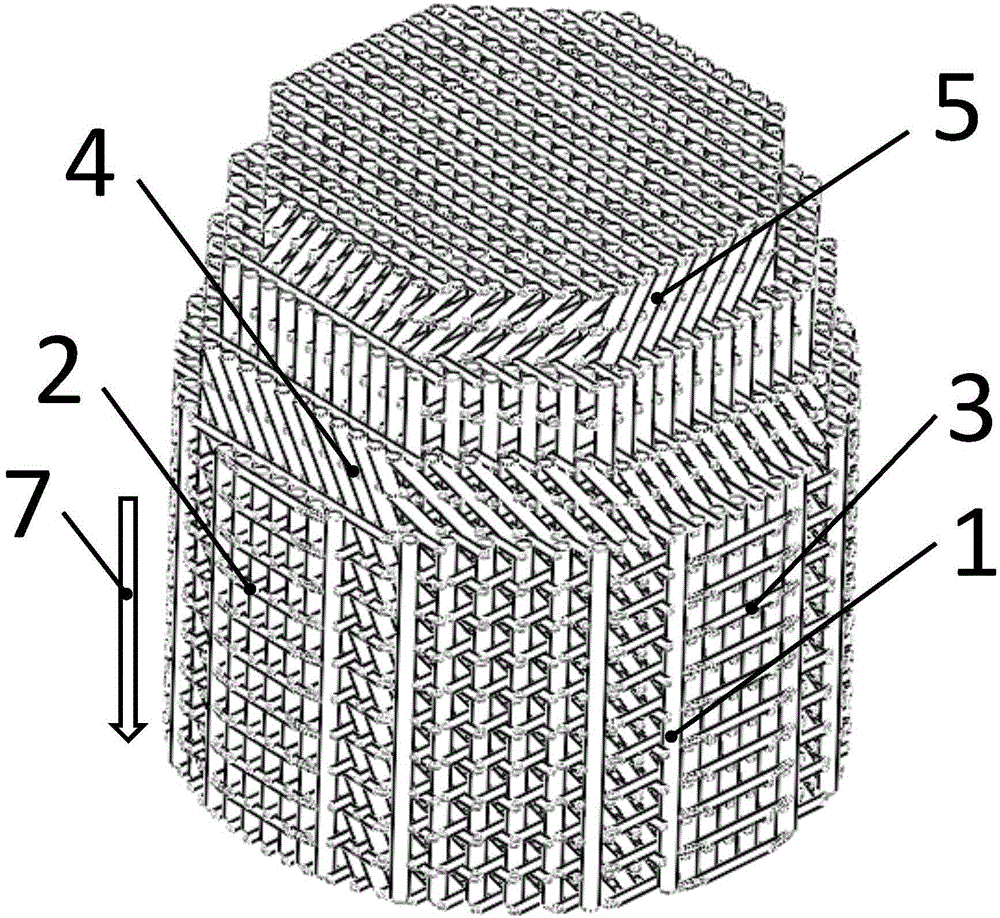

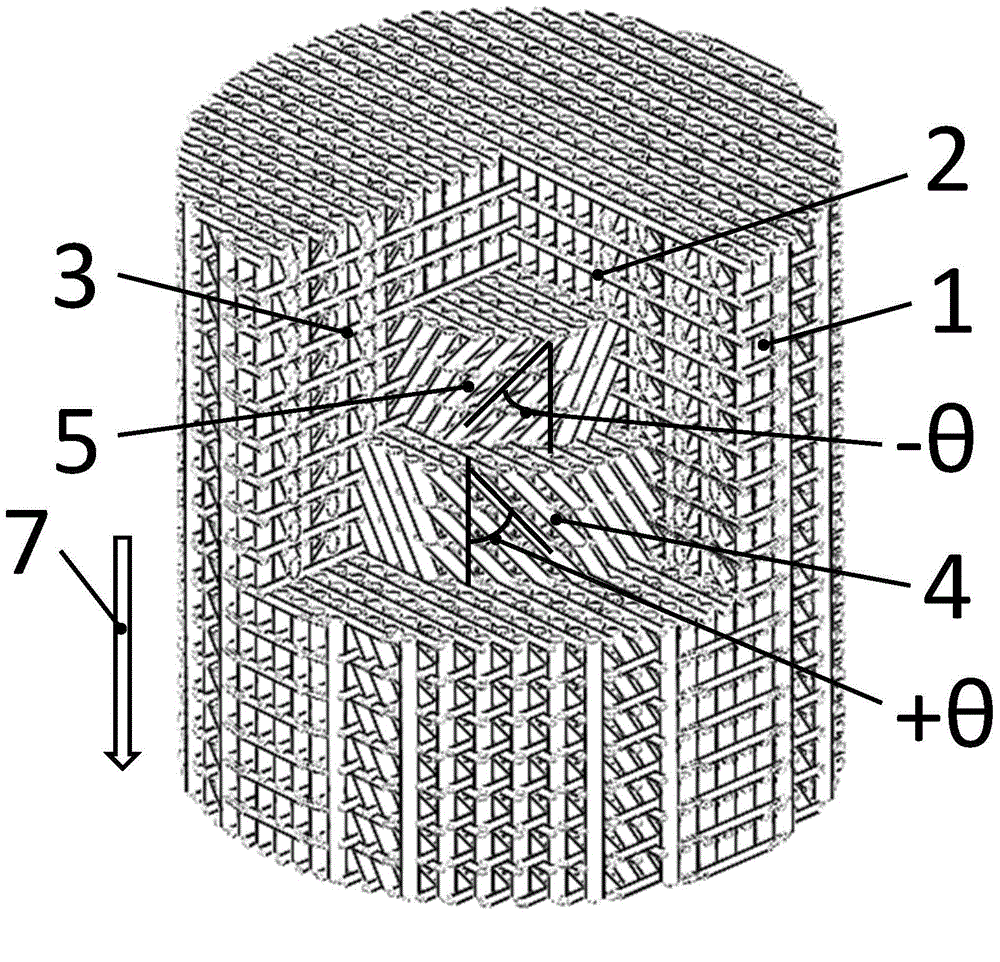

[0049] A solid cylindrical three-dimensional fabric with a cross-sectional diameter of 50mm was developed. 2 Warp yarn 1, weft yarn 2, normal yarn 3 and diagonal yarn 4 are all 12K carbon fibers. The density of yarn rows and columns in the cross-section of the fabric is 5×5 yarns / cm 2 , the movement mode is arranged as [45 / 0 / -45 / 0] 2 , where 45 represents the angle between the +θ oblique yarn and the length direction of the fabric is 45°, -45 represents the angle between the -θ oblique yarn and the length direction of the fabric is -45°, and 0 represents 0 parallel to the length direction of the fabric ° Warp yarn, the subscript represents the number of cyclic arrangements.

[0050] Fabric process parameter design:

[0051] (1) the number of rows (columns) N of yarns in the circumscribed regular quadrilateral of the fabric cross section: the number of yarn rows (columns) N=the diameter of the fabric cross section*yarn row (column) density+1=50 / 10*5 +1=26 rows (columns).

...

Embodiment 2

[0062] A solid cylindrical three-dimensional fabric with a cross-sectional diameter of 60mm was developed. The warp and diagonal yarns are 12K carbon fiber, and the weft and normal yarns are 6K carbon fiber. The density of yarn rows and columns in the cross-section of the fabric is 5×5 yarns / cm 2 , motion arrangement [+θ / 0 / -θ / 0 / 0] 2 , the weft density of the fabric is 8 threads / cm.

[0063] Fabric process parameter design:

[0064] (1) the row (column) number N of the yarn in the regular quadrilateral circumscribed by the fabric cross section: the yarn row (column) number N=the diameter of the fabric cross section×yarn row (column) density+1=60 / 10×5 +1=31 rows (columns);

[0065] (2) Diagonal yarn moving yarn number n: Diagonal yarn moving yarn number n=2.

[0066] (3) The number M of regular octagonal trajectories: the number M of regular octagonal trajectories = the number of arrangements of movement patterns × the number of cycles = 5 × 2 = 10.

[0067] (4) The angle ...

Embodiment 3

[0075] A solid cylindrical three-dimensional fabric with a cross-sectional diameter of 40mm was developed. The warp and diagonal yarns are 12K carbon fiber, and the weft and normal yarns are 9K carbon fiber. The density of yarn rows and columns in the cross-section of the fabric is 7×7 yarns / cm 2 , motion arrangement [+θ / -θ / 0] 3 , the weft density of the fabric is 3.5 threads / cm.

[0076] Fabric process parameter design:

[0077] (1) the number of rows (columns) N of yarns in the circumscribed regular quadrilateral of the fabric cross section: the number of yarn rows (columns) N=the diameter of the fabric cross section*yarn row (column) density+1=40 / 10*7 +1=29 rows (columns).

[0078] (2) Diagonal yarn moving yarn number n: Diagonal yarn moving yarn number n=1.

[0079] (3) The number M of regular octagonal trajectories: the number M of regular octagonal trajectories = the number of arrangement of movement modes × the number of cycles = 3 × 3 = 9.

[0080] (4) The angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com