Cold-rolled tin plate for beverage can bottom cover and production method thereof

A production method and tinplate technology are applied to cold-rolled tinplate for beverage can bottom covers and its production field, which can solve problems such as cracking and poor performance stability, and achieve simple process, good plate shape, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

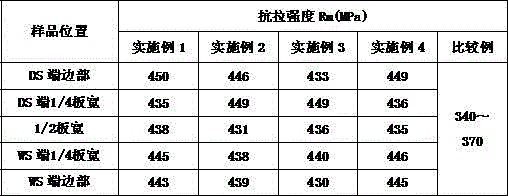

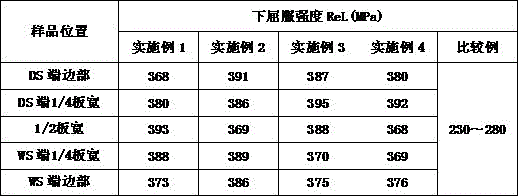

[0034] This implementation selects product specification to be 0.18mm*836mm, below in conjunction with embodiment 1~4 and comparative example---the Chinese patent application number is disclosed in the patent application of CN200510027291.4, the present invention is further described, as table 1~table 4 shown.

[0035] element C Si mn P S Alt N Ti O this invention 0.065~0.085 0.005~0.034 0.20~0.30 ≤0.018 ≤0.015 0.065~0.085 ≤0.004 Example 1 0.080 0.034 0.20 0.010 0.006 0.077 0.0040 Example 2 0.066 0.020 0.23 0.016 0.015 0.085 0.0029 Example 3 0.073 0.006 0.30 0.018 0.013 0.065 0.0023 Example 4 0.085 0.018 0.26 0.015 0.009 0.069 0.0032 comparative example ≤0.006 ≤0.03 0.1 ~0.2 ≤0.015 ≤0.015 0.025~0.075 ≤0.0030 0.03~0.08 ≤0.0040

[0036] Continuous casting slabs meeting the required chemical composition are obtained through converter smelting, with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com