Microbacterium capable of completely degrading zearalenone and application thereof

A gibberellone, completely degradable technology, applied in the field of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

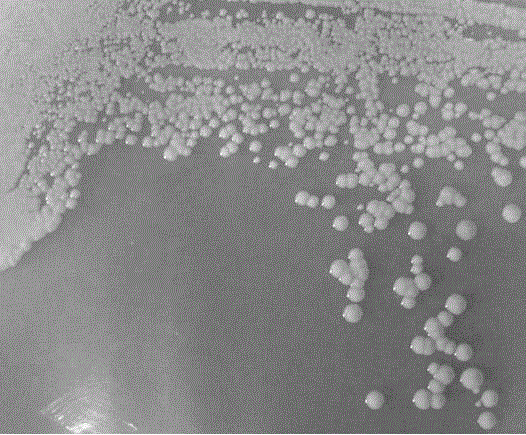

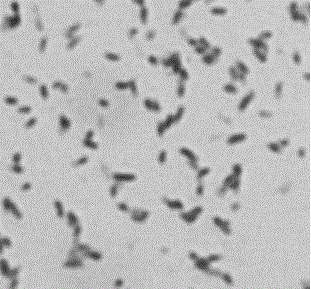

[0020] Example 1: Screening, isolation and identification of zearalenone-degrading strains

[0021] Soil samples were collected from turf (N36.34.243 E100.32.285) near Qinghai Lake on the Qinghai-Tibet Plateau. Take 2 g of soil samples, add 10 mL of 0.15M sodium chloride aqueous solution, shake for 30 min to fully disperse the samples, let stand at room temperature for 1 min, immediately take 1 mL of supernatant, spread on LB plates, and incubate at 30 °C until single For clonal growth, single colonies of different shapes were picked and inoculated in liquid LB medium (adding zearalenone with a final concentration of 25 μg / ml dissolved in methanol), cultured at 30°C for 2 days, centrifuged to obtain the supernatant, and washed with an appropriate amount of ethyl acetate. Extract, collect ethyl acetate and evaporate to dryness, dissolve the eluate with a small amount of methanol, and use TLC method (petroleum ether: acetone: ethyl acetate = 5:4:1 as the developing solvent) to...

Embodiment 2

[0023] Example 2: Microbacterium sp. Fermentation of FY1538

[0024] Microbacterium sp. The fermentation supernatant of FY1538 strain is used to degrade erythralenone, which needs to be induced by methanol. After isolation and purification of the strains, a single colony was picked and inoculated in 50 mL of LB medium, and methanol at a final concentration of 10 μl / ml was added, shaken and cultured at 30 °C for 48 h, and the fermentation broth was centrifuged at 12,000 rpm to obtain the fermentation supernatant.

Embodiment 3

[0025] Example 3: Microbacterium sp. Analysis of the ability of FY1538 fermentation supernatant to degrade erythralenone

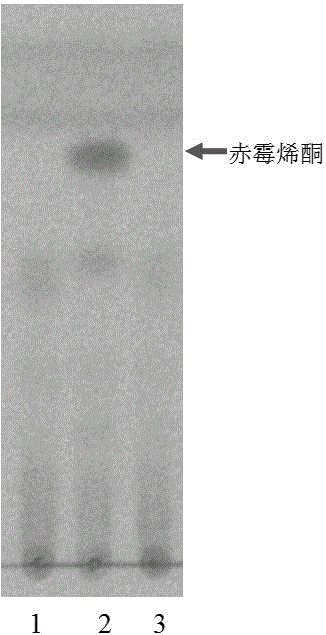

[0026]Take 500μl of the fermentation supernatant, add 25ug zearalenone, react in a water bath at 30°C for 24 hours, extract the reaction solution with 1000μl ethyl acetate, collect the ethyl acetate phase, evaporate to dryness and dissolve the eluate with a small amount of methanol, use TLC method ( MERCK company TLC silica gel plate 60F 254 , the developer is petroleum ether: acetone: ethyl acetate = 5:4:1) to check the residue of erythralenone. Such as image 3 as shown, Microbacterium sp. After 24 hours of catalytic reaction between FY1538 fermentation supernatant and zearalenone, no zearalenone in the reaction system could be detected by TLC method.

[0027] Further analysis by HPLC Microbacterium sp. The ability of FY1538 fermentation supernatant to degrade erythralenone at different reaction times. The HPLC chromatographic column was Agile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com