Gray sparkle silver printing ink

A gray and ink technology, applied in the field of printing inks, can solve the problems of ink use restrictions and achieve the effects of no bleeding, good adhesion, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

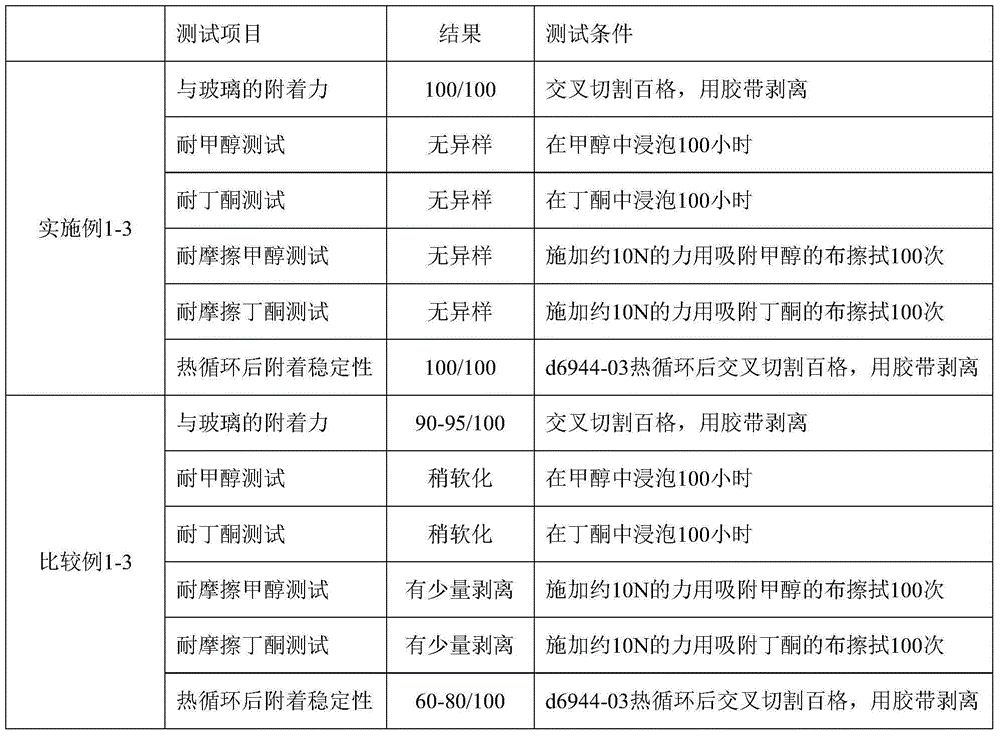

Examples

Embodiment 1

[0016] The gray flash silver ink of the present embodiment contains the HCP-213 black pigment of 8.8wt%, the HCP-214 transparent yellow pigment of 0.53wt%, the HCP-216 transparent blue pigment of 0.61wt%, the HF1000-800 light of 32.0wt% oil, 0.52wt% 607S silver powder, 0.31wt% 606Y silver powder, 2.2wt% phosphatidylserine, 1.5wt% glycerol carbonate propenyl ether, and the balance of Seiko T-926 thinner. The ink preparation process is as follows: (1) fully mix and dissolve the HF1000-800 varnish of 8wt% and the Seiko T-926 diluent of 10wt% in a stirring manner to obtain a dispersion solution; (2) mix the HCP- 213 black pigments, HCP-214 transparent yellow pigments, HCP-216 transparent blue pigments and the dispersion solution prepared in step (1), fully mixed with stirring to obtain the first mixed solution; (3) the glycerol carbonate Acryl ether, phosphatidylserine, 607S silver powder, and 606Y silver powder are fully mixed and dissolved with the remaining HF1000-800 varnish i...

Embodiment 2

[0018] The gray flash silver ink of the present embodiment contains the HCP-213 black pigment of 8.5wt%, the HCP-214 transparent yellow pigment of 0.55wt%, the HCP-216 transparent blue pigment of 0.65wt%, the HF1000-800 light of 28.0wt% Oil, 0.52wt% of 607S silver powder, 0.31wt% of 606Y silver powder, 2.5wt% of phosphatidylethanolamine, 1.2wt% of glycerol carbonate propenyl ether, and the balance of Seiko T-926 thinner. The ink preparation process is as follows: (1) fully mix and dissolve the HF1000-800 varnish of 8wt% and the Seiko T-926 diluent of 10wt% in a stirring manner to obtain a dispersion solution; (2) mix the HCP- 213 black pigments, HCP-214 transparent yellow pigments, HCP-216 transparent blue pigments and the dispersion solution prepared in step (1), fully mixed with stirring to obtain the first mixed solution; (3) the glycerol carbonate Acryl ether, phosphatidylethanolamine, 607S silver powder, and 606Y silver powder are fully mixed and dissolved with the remain...

Embodiment 3

[0020] The gray flash silver ink of the present embodiment contains the HCP-213 black pigment of 8.6wt%, the HCP-214 transparent yellow pigment of 0.55wt%, the HCP-216 transparent blue pigment of 0.63wt%, the HF1000-800 varnish of 30wt% , 0.52wt% of 607S silver powder, 0.31wt% of 606Y silver powder, 2.3wt% of phosphatidylcholine, 1.5wt% of glycerol carbonate propenyl ether, and the balance of Seiko T-926 thinner. The ink preparation process is as follows: (1) fully mix and dissolve the HF1000-800 varnish of 8wt% and the Seiko T-926 diluent of 10wt% in a stirring manner to obtain a dispersion solution; (2) mix the HCP- 213 black pigments, HCP-214 transparent yellow pigments, HCP-216 transparent blue pigments and the dispersion solution prepared in step (1), fully mixed with stirring to obtain the first mixed solution; (3) the glycerol carbonate Acryl ether, phosphatidylcholine, 607S silver powder, and 606Y silver powder are fully mixed and dissolved with the remaining HF1000-80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com