Detection sorting device and method for rice material

A sorting device and material technology, applied in the field of color sorting and detection, can solve problems such as misselection of transparent rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

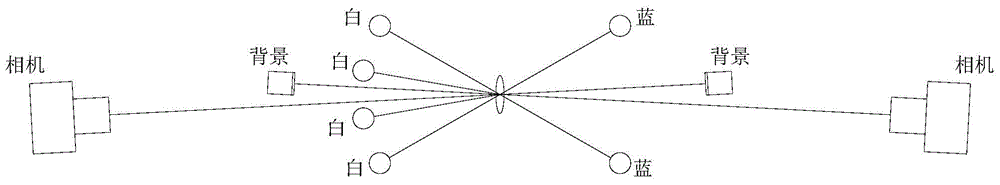

Embodiment 1

[0070] see figure 1 As shown, in this embodiment, the lighting component includes 4 groups of white light sources and 2 groups of blue light sources. The white light source is an LED or a fluorescent tube with a spectrum between 400-670nm, and the blue light source is an LED or a fluorescent tube with a spectrum between 400-500nm. The angle between the line between the white light source and the material and the chief ray is 15°-40°, preferably 30°; the angle between the line between the blue light source and the material and the chief ray is 15°-40°, preferably 30°, among which, The chief ray refers to the ray perpendicular to the falling surface of the material to be tested.

[0071] In this embodiment, it also includes a group of background light sources, including reflective and transmissive, the background is mainly to open up the difference with the material signal, the background light source is blue, the background light source is LED or fluorescent tube, and the spec...

Embodiment 2

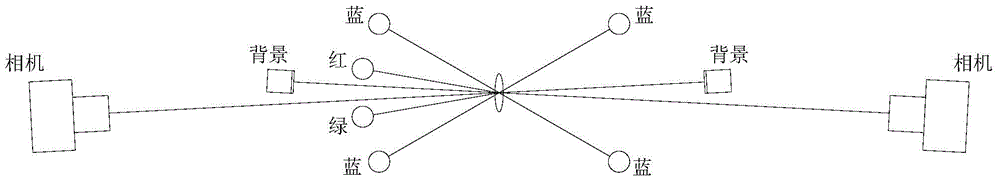

[0101] The difference between this embodiment and Embodiment 1 is that the camera on the light source side containing the blue light spectrum is a combination of red light, green light, and blue light, such as figure 2 As shown, at this time, the parameter setting methods in Embodiment 1 are also applicable.

Embodiment 3

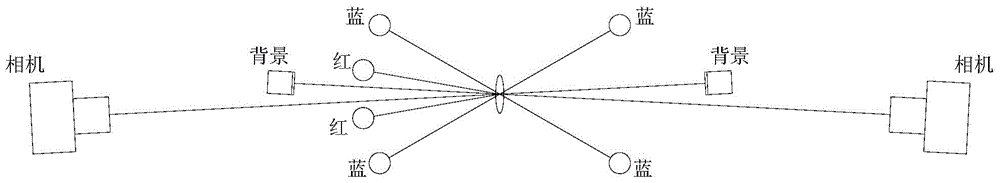

[0103] The difference between this embodiment and Embodiment 1 is that the camera on the light source side containing the blue light spectrum is a combination of red light and blue light, such as image 3 As shown, at this time, the parameter setting method in Embodiment 1 is also applicable, and it is only necessary to select the red threshold when either the red threshold or the green threshold can be selected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com