Up-flow type reactor

A reactor, upflow technology, used in chemical instruments and methods, petroleum industry, treatment with moving solid particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

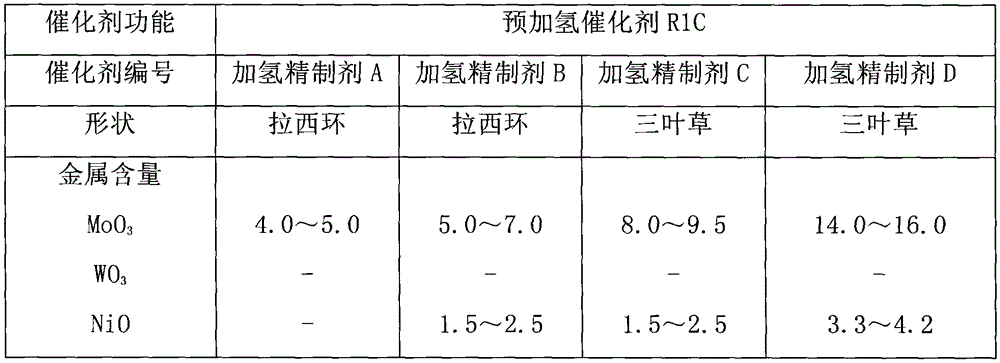

[0163] The properties of medium-temperature coal tar are shown in Table 1. It is separated into a light fraction with a weight yield of 82% mainly composed of hydrocarbons with a conventional boiling point lower than 480°C and a weight yield of 18% with a weight yield mainly composed of hydrocarbons with a conventional boiling point higher than 480°C. The coal tar pitch, the light fraction alone undergoes deep hydrogenation upgrading, and the coal tar pitch is used as a high aromatics raw material for HDS.

[0164] The hydrogen-donating hydrocarbon stream SHS is selected from the pre-hydrogenated oil R1P obtained in the pre-hydrogenation reaction process R1, the amount is 5 times that of the high-aromatic raw material HDS, and is obtained through the gas-liquid separation process of the pre-hydrogenation reaction effluent R1P. At this time, the supply The hydrogen hydrocarbon precursor stream is the high-aromatic raw material HDS itself; the weight ratio of the hydrogen-donatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com