Boneless cutting and processing technology for pickled spanish mackerel

A processing technology and technology of mackerel, which is applied in the preservation of meat/fish by freezing/cooling, the function of food ingredients, food preparation, etc., can solve the problems of long storage time, damage to nutrients, poor taste, etc., and achieves convenient and simple consumption. , The effect of less loss of nutrients and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

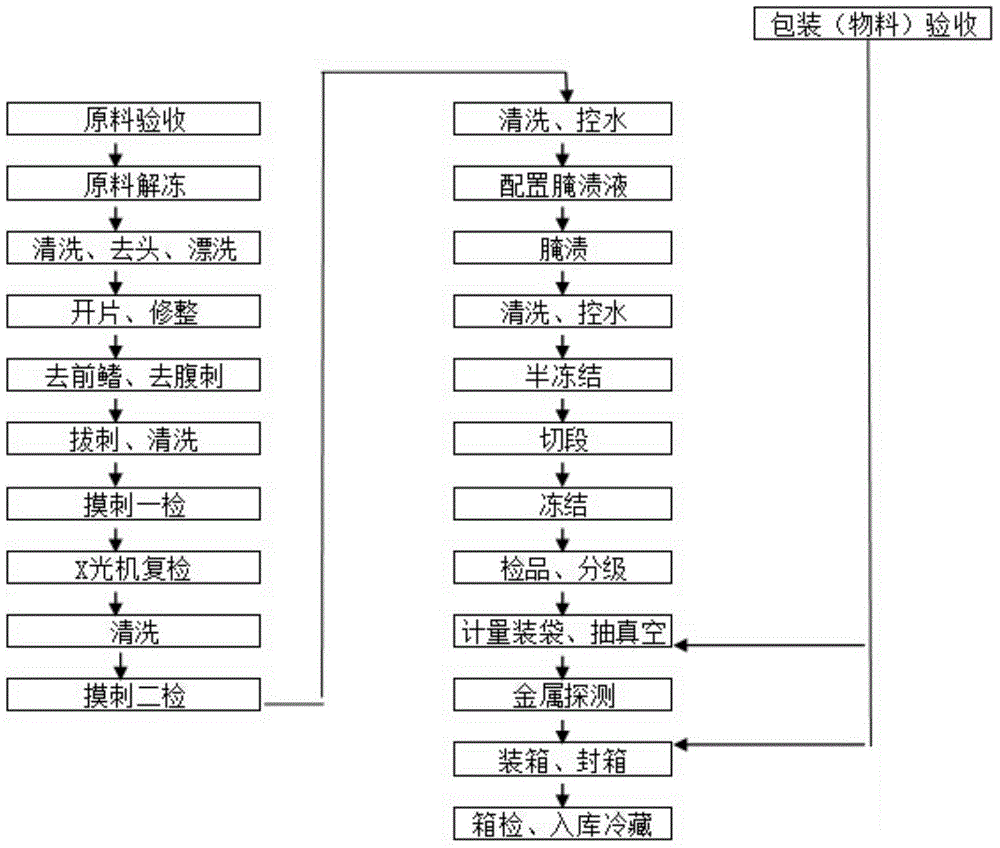

[0056] The boneless and cut processing technology of pickled mackerel of the present embodiment comprises the following steps:

[0057] Step 1: Raw Material Acceptance

[0058] The surface of the fish body is shiny, the freezing hardness is good, the surface of the raw material body has no yellowing, no air-drying, no corruption, the smell is normal fish smell, no peculiar smell, and the packaging is intact without contamination; the center temperature of the fish body is below -18°C;

[0059] Step 2: Thaw the ingredients

[0060] Natural thawing, after extracting the raw materials from the large warehouse, place them on the thawing rack in turn, and control the product temperature at -5 °C ~ -2 °C;

[0061] Step 3: Wash, De-hair, Rinse

[0062] After the raw materials are thawed, put the fish under the long running water for single cleaning to wash off the foreign matter and impurities on the surface; take the fish gill cover as a reference, cut at 1cm from the front of the...

Embodiment 2

[0102] The boneless and body-cut processing technology of pickled mackerel of the present embodiment is the same as embodiment 1 except the following differences:

[0103] Step 3 When removing the head: take the fish eye as a reference, and cut the fish eye 1cm behind.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com