Method for manufacturing anode materials for sodium ion batteries and application of anode materials

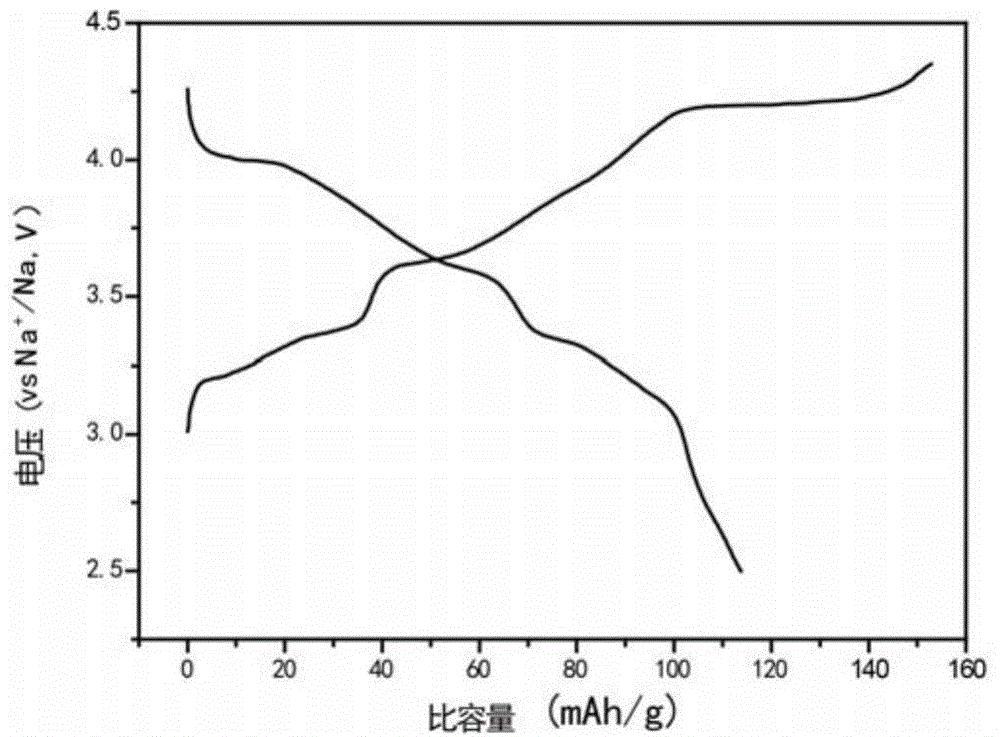

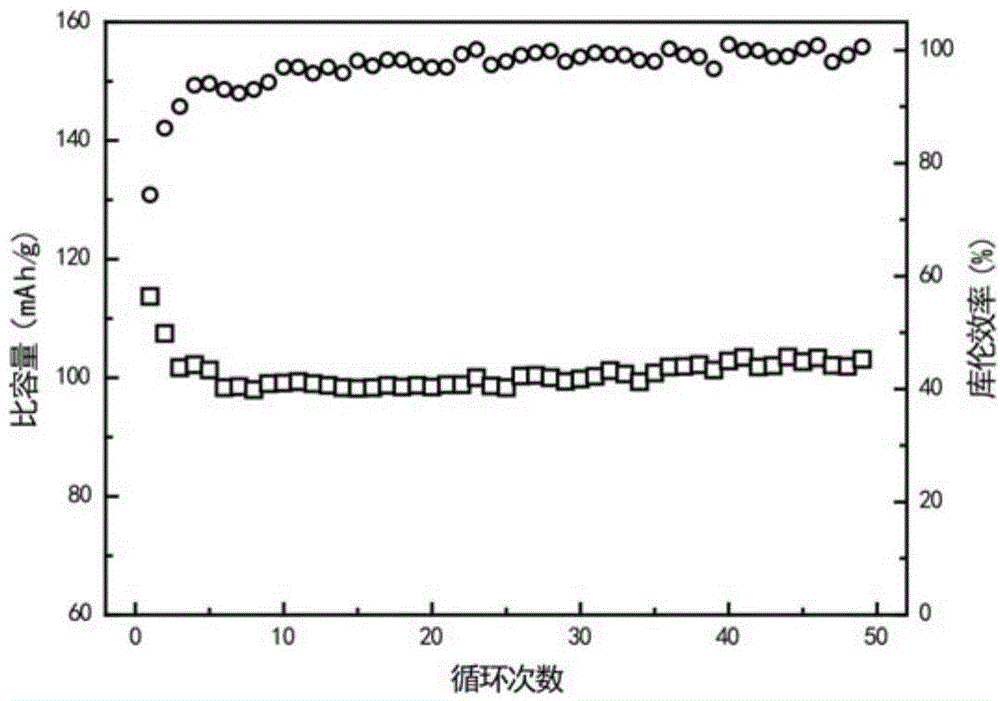

A sodium-ion battery and cathode material technology, applied in the field of electrochemical power sources and energy materials, can solve the problems of phase change structure, collapse, poor cycle stability, etc., and achieve the advantages of easy availability of raw materials, high average discharge voltage, and high cycle specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of 5% Mg-doped Na 2 / 3 mn 1-x-y Ni y Mg x o 2 (x=0.05, y=0.28) positive electrode material

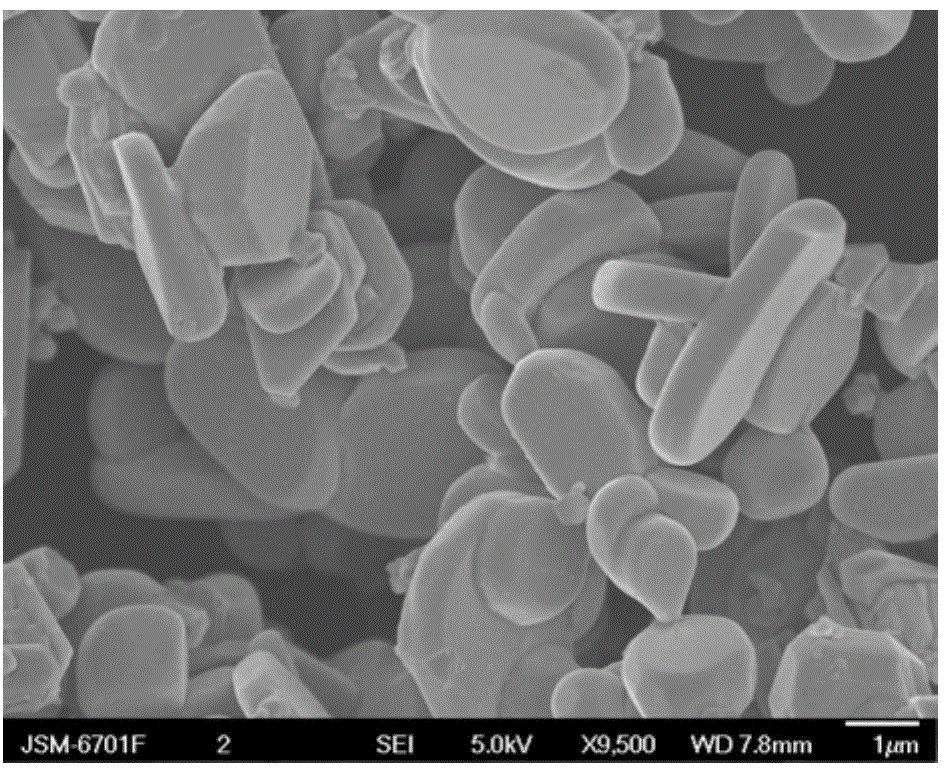

[0036] Accurately weigh the corresponding proportion of NaNO 3 , Mn(NO 3 ) 2 , Ni(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O was dissolved in distilled water and stirred. Add the chelating agent citric acid solution dropwise and stir to obtain a gel. Dry and heat-treat the precursor at 120°C. Grind and calcined at 900°C for 15h-24h to obtain black powder. The size of the obtained powder particles is 1-2μm, and the density is 5.1g / cm 3 .

[0037] (2) Preparation of 5% Mg-doped Na 2 / 3 mn 1-x-y Ni y Mg x o 2 Composite cathode

[0038] Mix the positive electrode material prepared above with Super P and the binder polyvinylidene fluoride at a mass ratio of 0.75:0.15:0.10, add the solvent N-methylpyrrolidone, and obtain the Composite positive electrode.

[0039] (3) Assembling sodium-ion batteries

[0040] The composite positive electrode prepared a...

Embodiment 2

[0044] (1) Preparation of 5% Li-doped Na 2 / 3 mn 1-x-y Ni y Li x o 2 (x=0.05, y=0.3) positive electrode material

[0045] Accurately weigh the corresponding proportion of NaNO 3 , Mn(NO 3 ) 2 , Ni(NO 3 ) 2 ·6H 2 O, LiNO 3 Dissolve in distilled water and stir. Add the chelating agent citric acid solution dropwise and stir to obtain a gel. Dry and heat-treat the precursor at 120°C. Grind and calcined at 900°C for 15h-24h to obtain black powder. The size of the powder particles is 2-3μm and the density is 4.9g / cm 3 .

[0046] (2) Preparation of 5% Li-doped Na 2 / 3 mn 1-x-y Ni y Li x o 2 Composite cathode

[0047] Mix the positive electrode material prepared above with Super P and the binder polyvinylidene fluoride at a mass ratio of 0.75:0.15:0.10, add the solvent N-methylpyrrolidone, and obtain the Composite positive electrode.

[0048] (3) Assembling sodium-ion batteries

[0049] The composite positive electrode prepared above is assembled with the sodium ...

Embodiment 3

[0053] Preparation of 0.5% Al-doped Na 2 / 3 mn 1-x-y Ni y al x o 2 (x=0.005, y=0.1) positive electrode material, the size of the obtained powder particles is 1.5-3μm, and the density is 5.0g / cm 3 . All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com