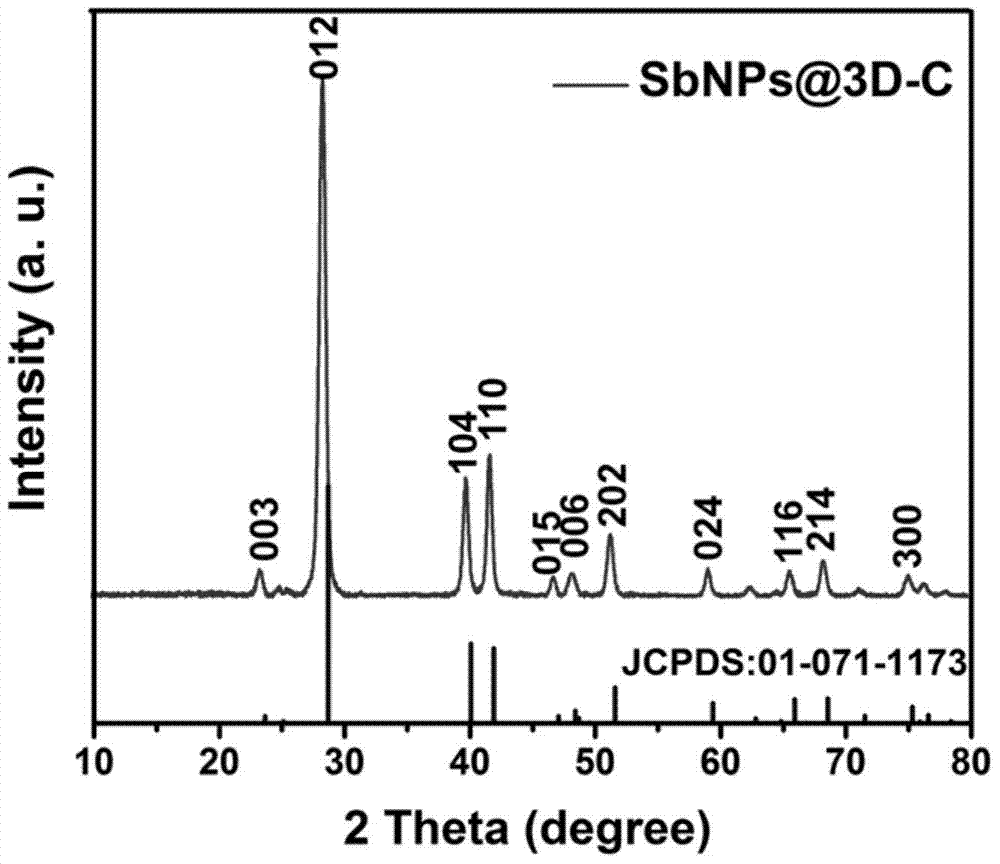

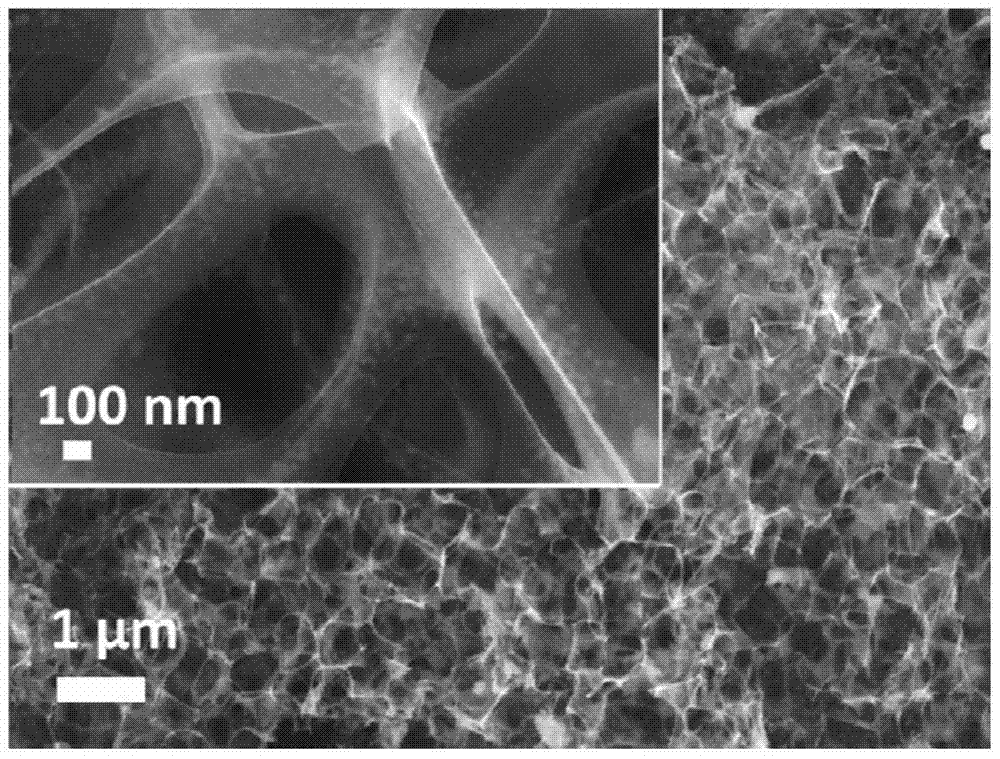

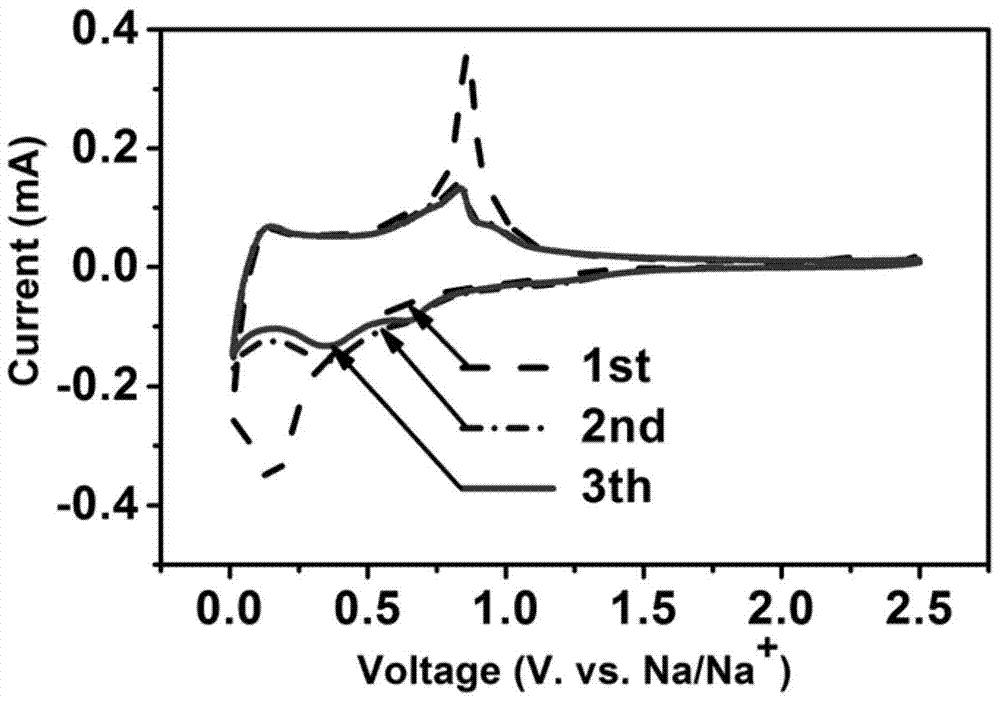

Three-dimensional-antimony/carbon network structure composite material, preparation method and application thereof

A technology of network structure and composite material, which is applied in the field of three-dimensional-antimony/carbon network structure composite material and its preparation, and achieves the effects of improving cycle stability, high structural stability and short operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Add 0.5g polyvinylpyrrolidone (PVP, K30) and 2.5g citric acid monohydrate into 50mL distilled water, stir until dissolved, and obtain a colorless transparent solution;

[0035] 2) Add 14.7g of sodium chloride to the above solution, mix and stir until dissolved;

[0036] 3) Add 0.456g of antimony chloride to the mixed solution, raise the temperature to 50°C, and stir for 30 minutes to finally obtain a colorless and transparent precursor solution;

[0037] 4) Rapidly transfer the precursor solution, pour liquid nitrogen into the solution, and quickly freeze the liquid nitrogen to obtain a crystalline solid, and dry it in a freeze dryer for 48 hours to sublimate the aqueous solution and maintain its shape;

[0038] 5) Calcining the dried product in a hydrogen atmosphere, the heating rate is 2°C / min, the calcination temperature is 700°C, and the calcination time is 6h;

[0039] 6) The obtained black product was washed with deionized water to remove NaCl, washed 3 times,...

Embodiment 2

[0045] 1) Add 0.5g polyvinylpyrrolidone (PVP, K30) and 2.5g citric acid monohydrate into 50mL distilled water, stir until dissolved, and obtain a colorless transparent solution;

[0046] 2) Add 11.76g of sodium chloride to the above solution, mix and stir until dissolved;

[0047] 3) Add 0.456g of antimony chloride to the mixed solution, raise the temperature to 50°C, and stir for 30 minutes to finally obtain a colorless and transparent precursor solution;

[0048] 4) Rapidly transfer the precursor solution, pour liquid nitrogen into the solution, and quickly freeze the liquid nitrogen to obtain a crystalline solid, and dry it in a freeze dryer for 48 hours to sublimate the aqueous solution and maintain its shape;

[0049] 5) Calcining the dried product in a hydrogen atmosphere, the heating rate is 2°C / min, the calcination temperature is 700°C, and the calcination time is 6h;

[0050] 6) The obtained black product was washed with deionized water to remove NaCl, washed 3 times...

Embodiment 3

[0053] 1) Add 0.5g polyvinylpyrrolidone (PVP, K30) and 2.5g citric acid monohydrate into 50mL distilled water, stir until dissolved, and obtain a colorless transparent solution;

[0054] 2) Add 8.82g of sodium chloride to the above solution, mix and stir until dissolved;

[0055] 3) Add 0.456g of antimony chloride to the mixed solution, raise the temperature to 50°C, and stir for 30 minutes to finally obtain a colorless and transparent precursor solution;

[0056] 4) Rapidly transfer the precursor solution, pour liquid nitrogen into the solution, and quickly freeze the liquid nitrogen to obtain a crystalline solid, and dry it in a freeze dryer for 48 hours to sublimate the aqueous solution and maintain its shape;

[0057] 5) Calcining the dried product in a hydrogen atmosphere, the heating rate is 2°C / min, the calcination temperature is 700°C, and the calcination time is 6h;

[0058] 6) The obtained black product was washed with deionized water to remove NaCl, washed 3 times,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com