Preparation method of dichloro(1,5-cyclooctadiene) platinum (II)

A technology of cyclooctadiene and potassium chloroplatinite, which is applied in the field of preparation of platinum group metal compounds, can solve problems such as difficult recovery or recycling, harsh conditions and danger, and excessive COD, so as to save precious metal platinum and ensure safety The effect of high stability and low COD consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

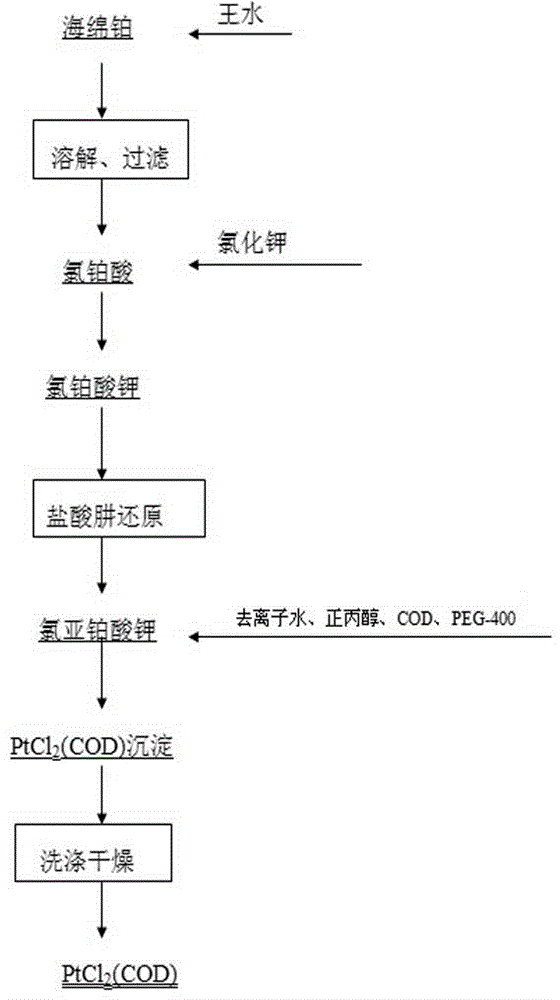

Embodiment 1

[0011] Potassium chloroplatinite can also be prepared by purchasing finished potassium chloroplatinite. The specific preparation method will be prepared by reacting chloroplatinic acid solution prepared from platinum sponge with potassium chloride solution to prepare potassium chloroplatinate, and then hydrazine hydrochloride Potassium chloroplatinite is used as a reducing agent to reduce potassium chloroplatinate to prepare pharmaceutical intermediates; the preparation process of the chloroplatinic acid solution is to react sponge platinum with aqua regia, and after the reaction stops, add concentrated hydrochloric acid dropwise to catch the nitrate until the system stops. Until brown nitrogen oxides appear again, add appropriate amount of water to catch acid, filter and heat the filtrate to 100-200g / L; chloroplatinic acid solution reacts with potassium chloride to prepare potassium chloroplatinate solution. / L of chloroplatinic acid solution is added dropwise to the potassium...

Embodiment 2

[0014] The specific implementation rules are the same as in Example 1, except that the potassium chloroplatinite is 300g, the deionized water is 6L, and n-propanol is 6L. They are added to a 50L spherical glass reactor, and the n-propanol solution of COD (1.0:1) is 1.2 L, PEG-400 600ml, reacted in an oil bath at 55°C for 4 hours; the product yield was 90.5%; the elemental analysis results were C: 25.15%, H: 3.123%, Pt: 52.13%.

Embodiment 3

[0016] The specific implementation rules are the same as example 1, except that the potassium chloroplatinite 500g purchased is used, and the added deionized water is 10L, and 10L of n-propanol is added to a 50L spherical glass reactor, and the n-propanol solution of COD (1.0 :1) 2L, PEG-400 1L, reacted in an oil bath at 55°C for 4h; the product yield was 90.5%; the elemental analysis results were C: 25.56%, H: 3.145%, Pt: 52.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com