Wet desulfurization wastewater zero emission process and device thereof

A technology of wet desulfurization and process equipment, which is applied in the field of wet desulfurization wastewater zero discharge process and its equipment in thermal power plants, can solve the problems of failure to popularize widely, high investment cost and high energy consumption in operation cost, and achieve low investment cost and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

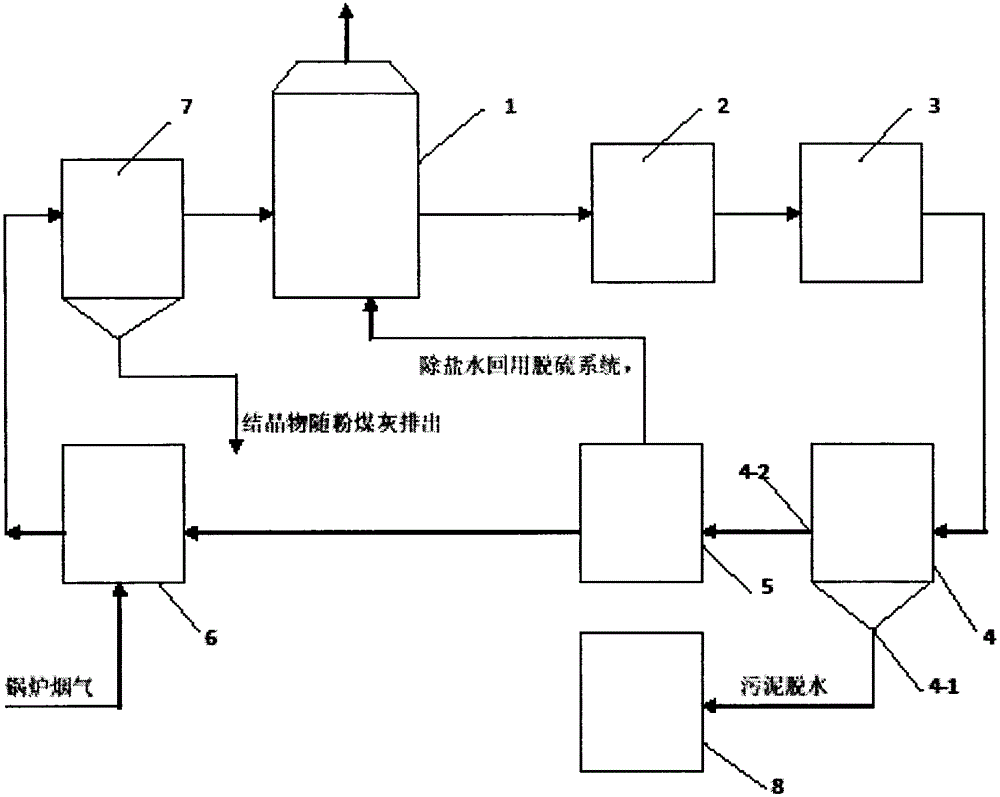

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] The invention provides a process method for zero discharge of wet desulfurization wastewater, comprising the following steps:

[0031] 1) The desulfurization wastewater collected from the gypsum dehydration device enters the flocculation device, and the desulfurization wastewater is softened, flocculated, clarified, and filtered. The separated clarified water meets the secondary treatment inlet standard, and the sludge is sent to the sludge dewatering device for further processing. dehydration.

[0032] In the flocculation device, by adding alkali, complexing agent, flocculant and coagulant to adjust the pH value, it can remove suspended solids and heavy metals in the wastewater, soften the water body, and adjust the water quality.

[0033]Wherein, the flocculation device adopts an electrocoagulation or chemical flocculation device. Specifically, electrocoag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com